Ion plating apparatus that prevents wasteful consumption of evaporation material

A technology of ion coating and plasma beam, applied in the field of ion coating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

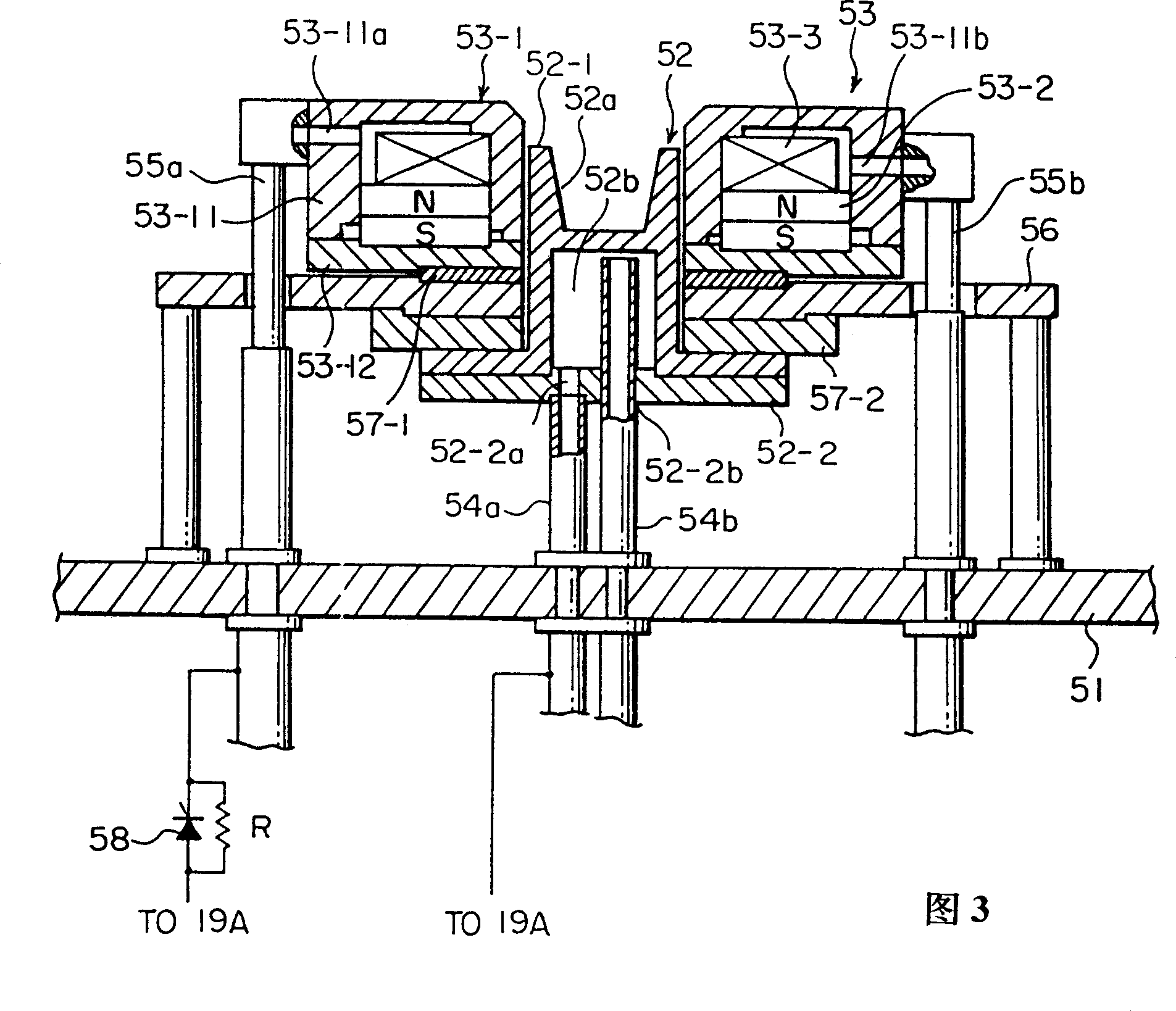

[0012] The preferred embodiment of the present invention is described as follows:

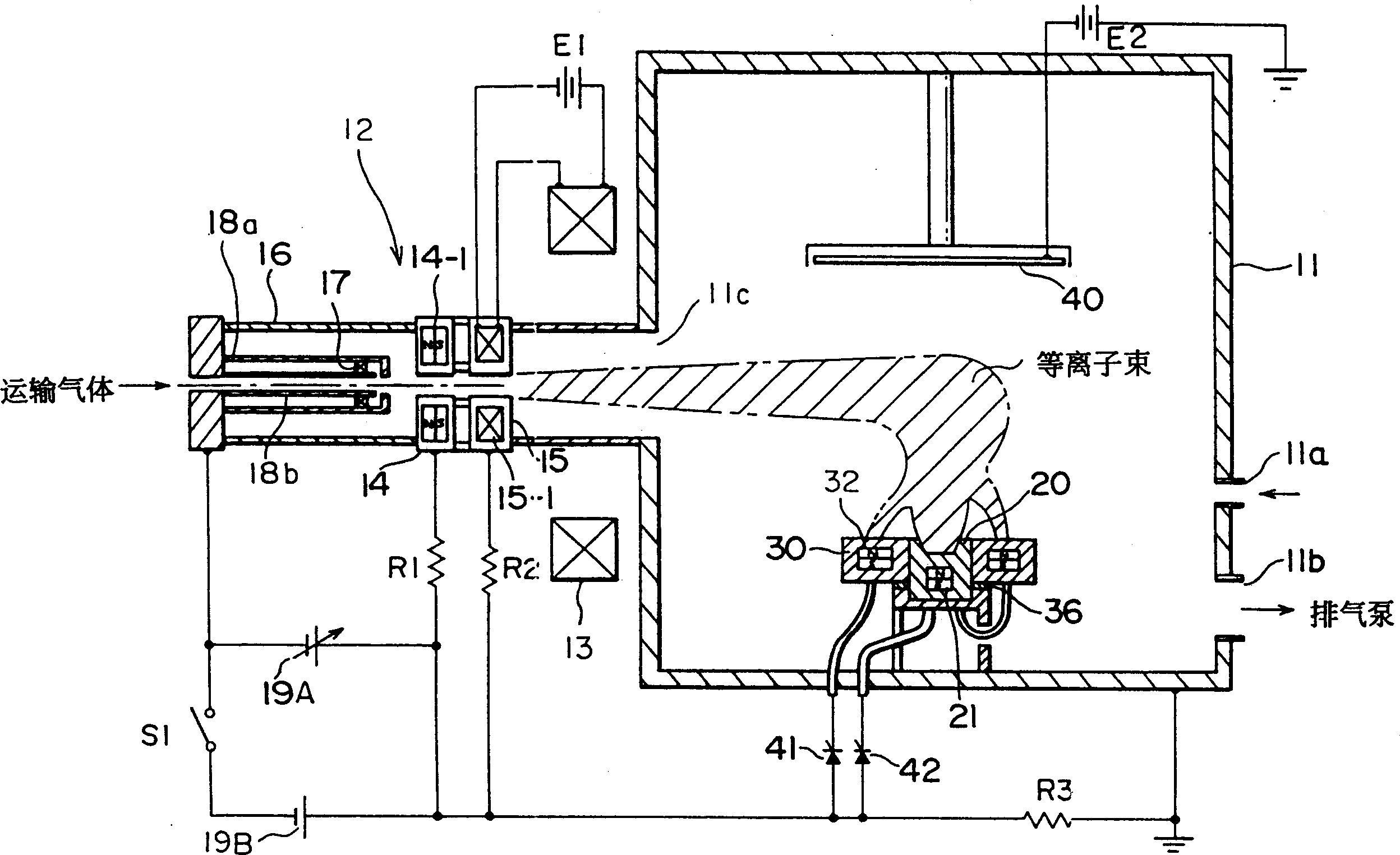

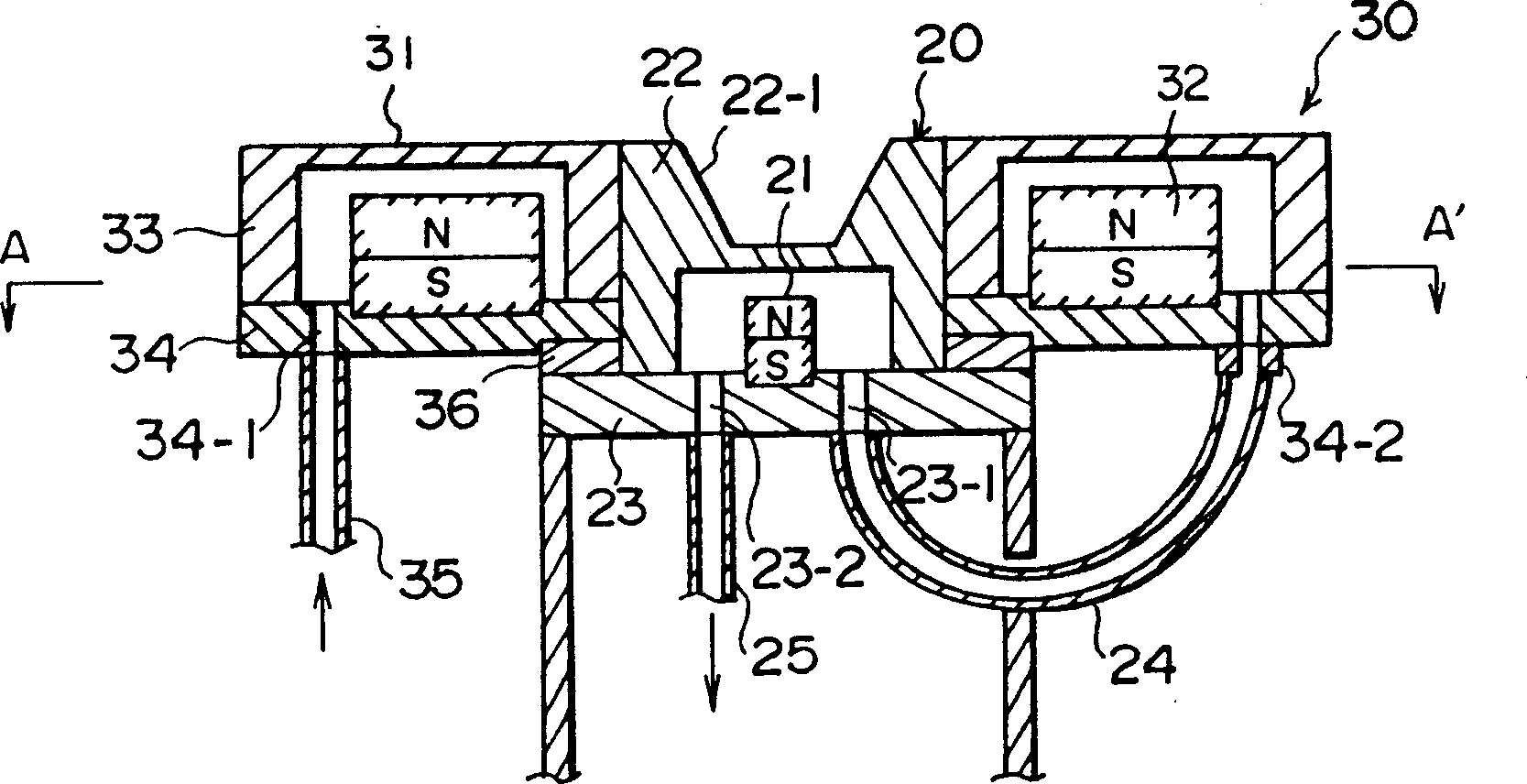

[0013] refer to figure 1 and figure 2 It is a conventional ion coating device shown in order to better understand the essence of the present invention.

[0014] exist figure 1 Among them, the ion coating device includes a vacuum chamber 11, and on the side wall of the vacuum chamber 11, there are an inlet 11a and an outlet 11b for leading in and out gases such as argon. The inlet 11a is connected to an air source (not shown), and the outlet 11b is connected to an exhaust pump (not shown). The side wall of the vacuum chamber 11 also has a hole 11c. The hole 11c houses a plasma beam generator 12 having a pressure gradient. Around the outer surface of the hole 11c is mounted a control coil 13 for guiding the plasma beam.

[0015] The plasma beam generator 12 has a first intermediate electrode 14 and a second intermediate electrode 15 for confining the plasma beam. The first and second inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com