Water-proof zipper and its making method

A waterproof zipper, the technology of manufacturing method, applied in the direction of sliding fastener components, application, fasteners, etc., can solve the problems of difficult control of heating treatment, etc., and achieve the effect of good waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

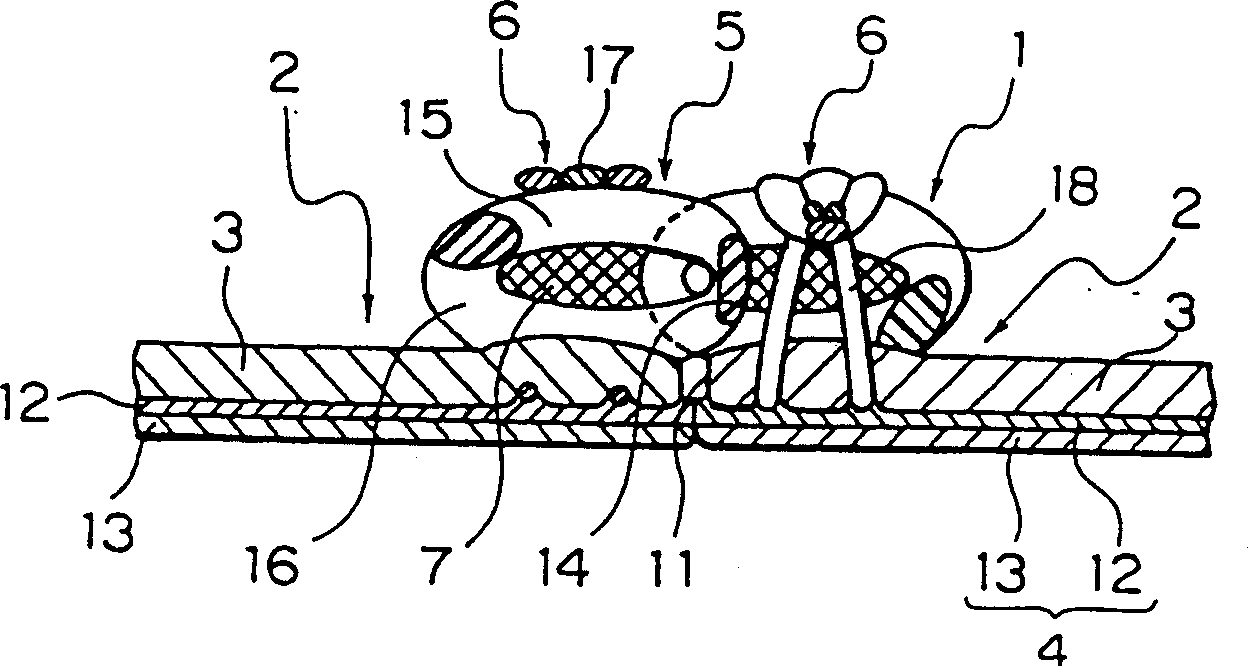

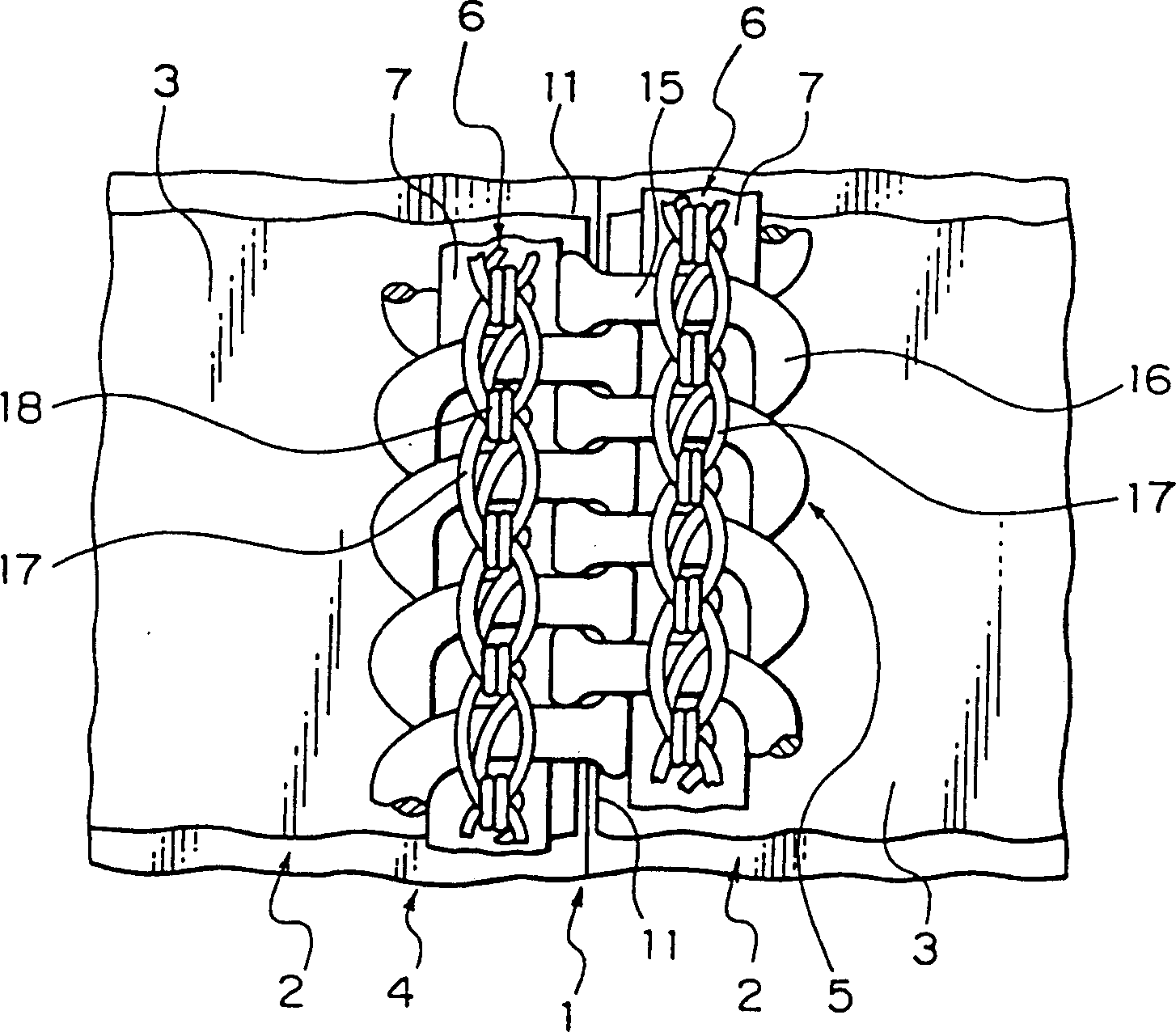

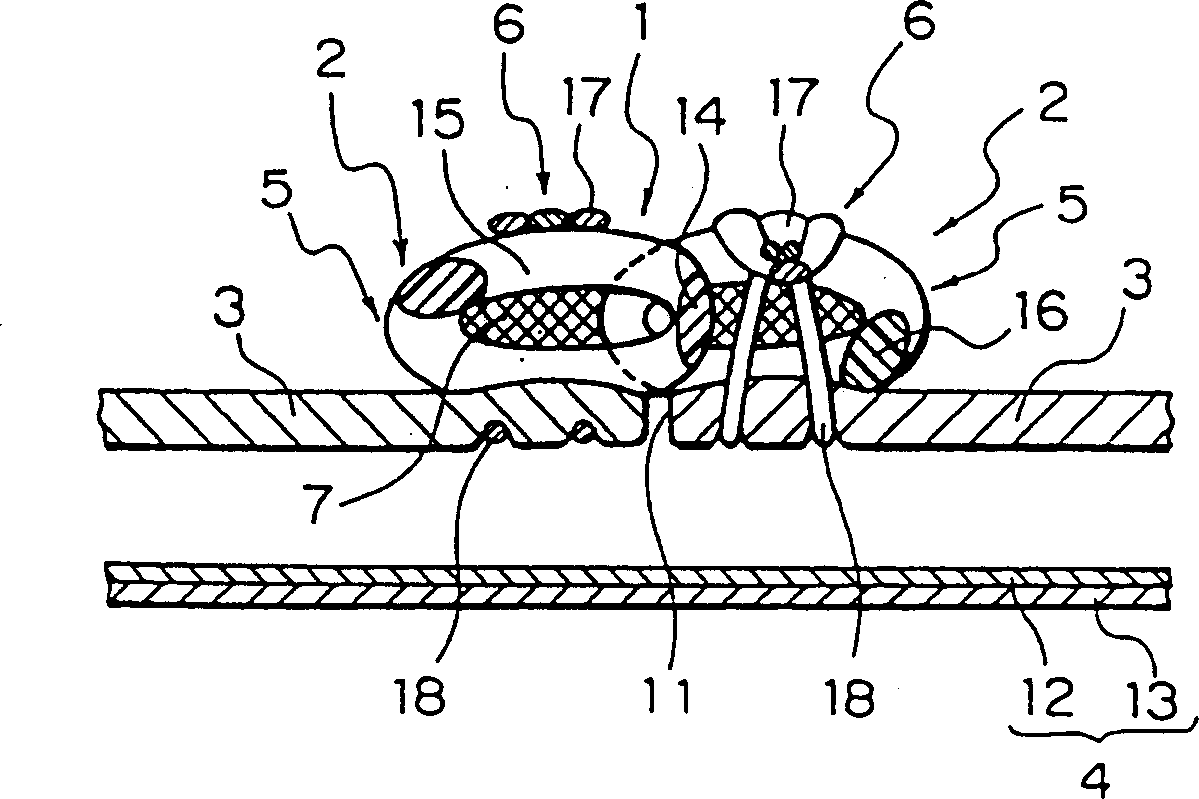

[0042] Hereinafter, the embodiments of the waterproof zipper of the present invention and the manufacturing method thereof will be described in detail with reference to the accompanying drawings.

[0043] In the zipper with the waterproof effect of the present invention, the zipper tape 3 is woven or knitted by synthetic resin fibers, such as polyamide fibers and polyethylene fibers, and is composed of a double-layer composite composed of a low-melting resin layer 12 and a high-melting resin layer 13. The resin composite film 4 is fused to one surface of the fastener tape by pressing and heating. Therefore, this zipper has a waterproof function.

[0044] In such figure 1 with figure 2 In the first embodiment of a zipper with a waterproof effect shown, a core thread 7 passes through the inside of a linear loop-shaped element 5 made of synthetic resin monofilament such as polyamide and polyethylene. The leg 15 is sewn on the surface of the side 11 of the zipper tape 3 with a sewing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com