Lithium ion battery thermal runaway safety assessment method under vibration working condition

A lithium-ion battery, safety assessment technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of increased voltage change rate and current change rate, inaccurate evaluation results, etc., to prevent misjudgment or missed judgment , the effect of an accurate assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order for those skilled in the art to better understand the technical solutions of the present application, the present application will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present application. .

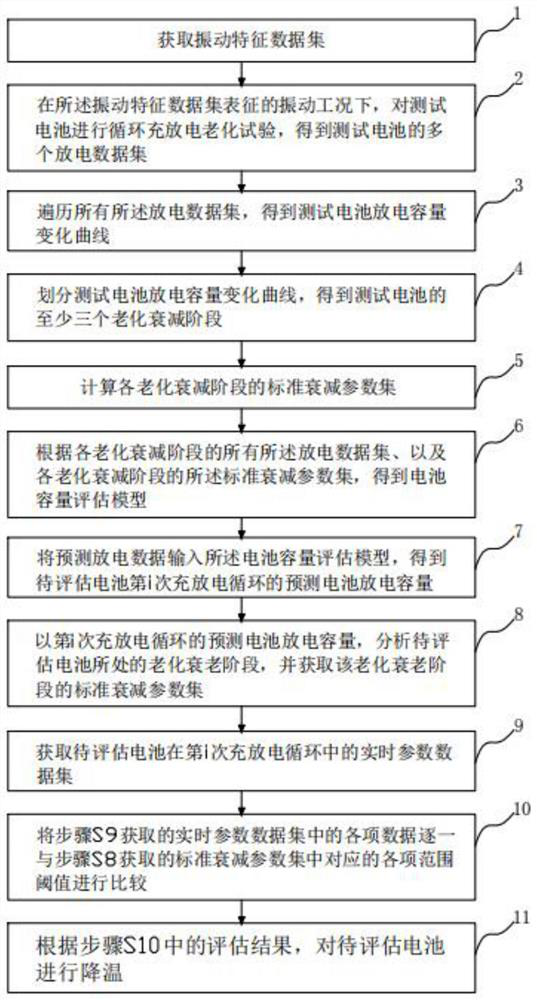

[0049] Please refer to figure 1, this embodiment provides a thermal runaway safety assessment method for a lithium-ion battery under vibration conditions, the method includes the following steps:

[0050] The method includes the following steps:

[0051] S1. Acquire a vibration characteristic data set, where the vibration characteristic data set is road vibration characteristic data collected on the spot.

[0052] Specifically, a vibration working condition is selected, and its vibration characteristic data is collected on the spot. The vibration working condition can be, for example, a highway workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com