Kettle type heat exchanger with fixed tube plate

A technology for fixing tube sheets and heat exchangers, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as difficult to guarantee welding quality, wear-through of heat exchange tube walls, and limited spacing , to achieve safe and reliable operation, prolong service life, and improve stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

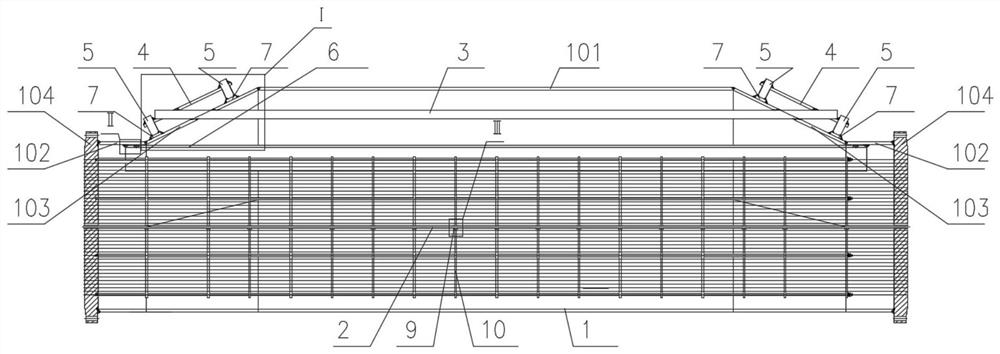

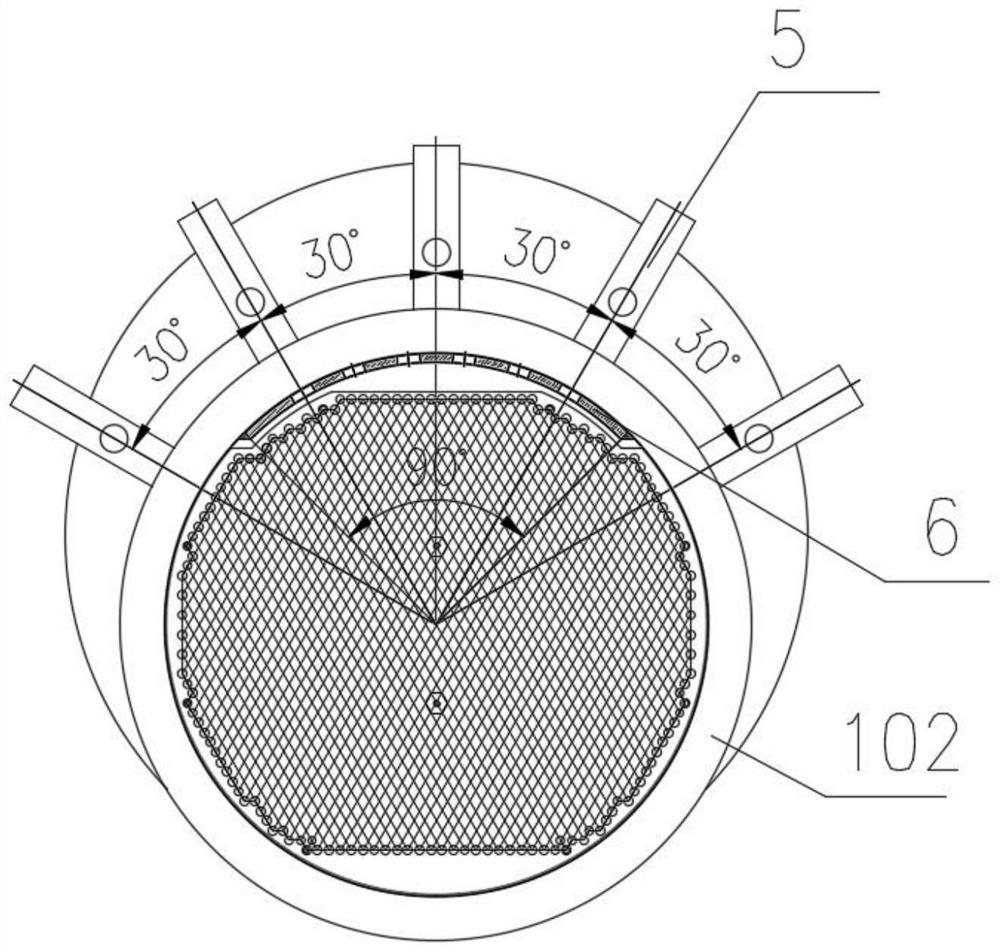

[0030] like Figure 1-6 As shown, a fixed tube sheet kettle type heat exchanger in this embodiment includes a shell side cylinder 1, tube sheets 104 located at both ends of the shell side cylinder 1, and heat exchange tubes 2 located inside the shell side cylinder 1, The shell-side cylinder 1 includes a large-diameter section cylinder 101 that is integrally connected and has a common bottom end, and a small-diameter section cylinder 102 located at both ends of the large-diameter section cylinder 101. The small-diameter section cylinder 102 and the large-diameter section cylinder 101 are eccentric. Cone 103 is connected.

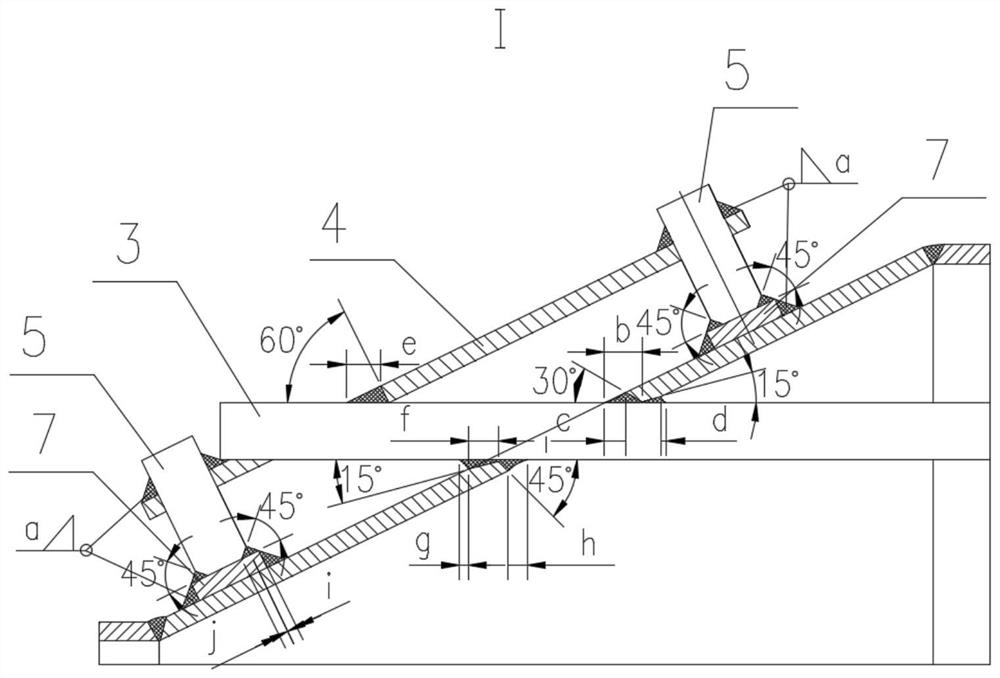

[0031] The two sets of eccentric cones 103 are connected by 6 tie rods 3, and the tie rod 3 and the eccentric cone 103 are fixed by double-sided welding, and the overhanging ends of the tie rod 3 are reinforced and fixedly connected, specifically the extension end sleeve of the tie rod 3 The two ends of the fixed plate 4 are welded and fixed with the reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com