Cross-linked polyethylene insulated parallel bunched aerial cable and processing equipment

A cross-linked polyethylene, overhead cable technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of winding influence, equipment stability influence, cable winding and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

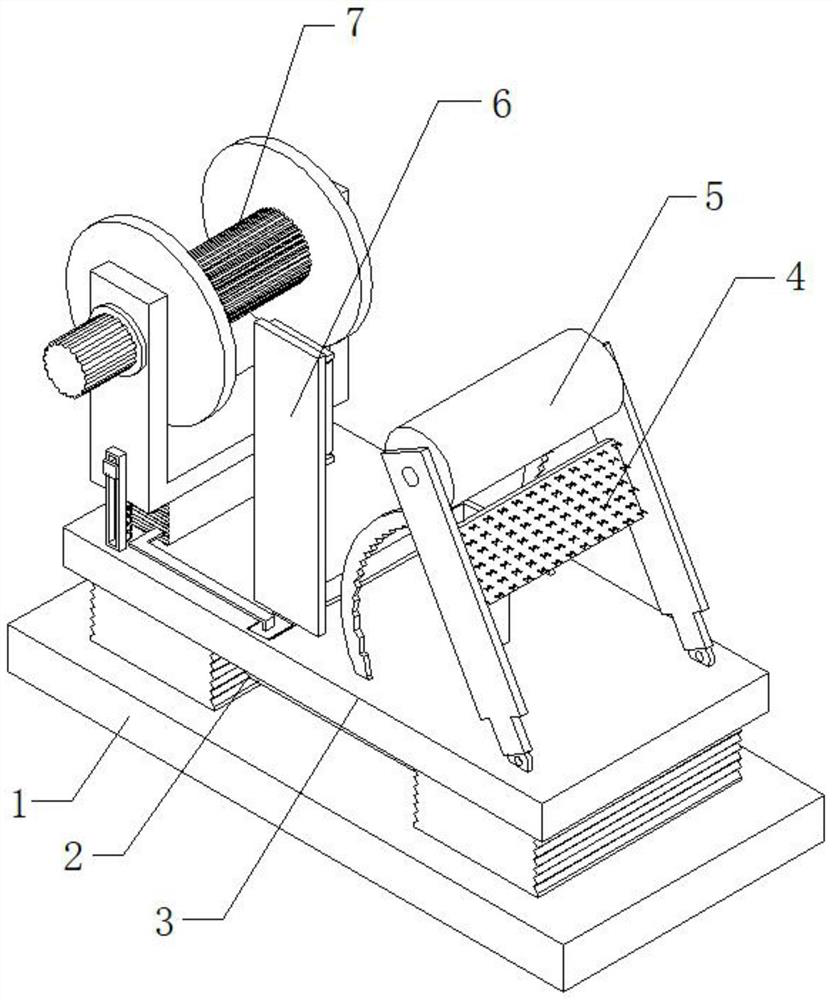

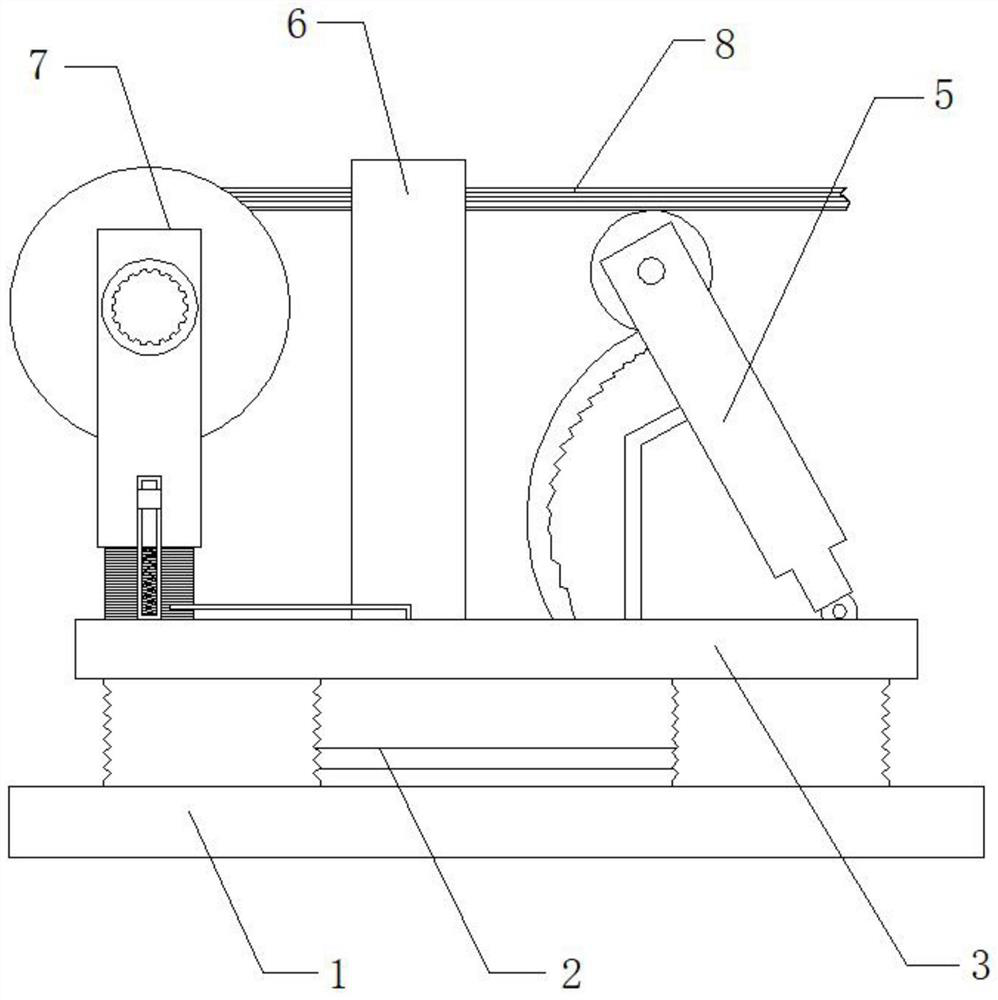

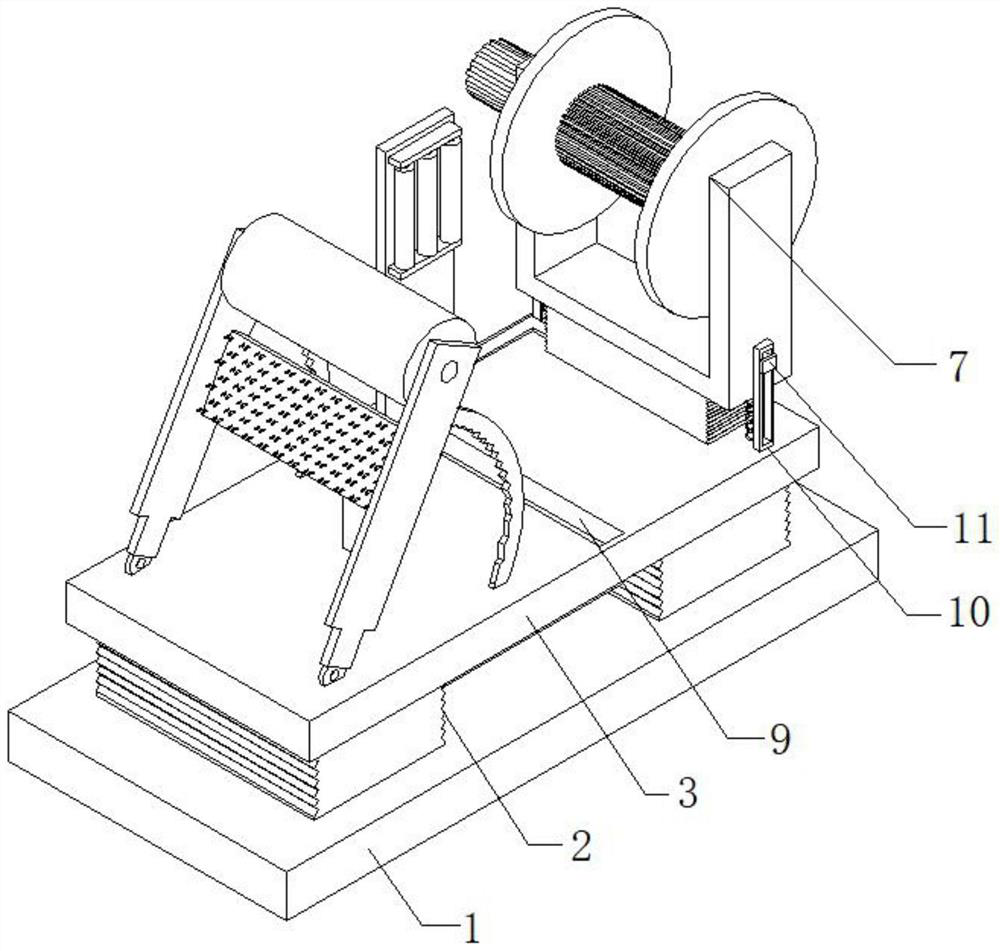

[0027] refer to Figure 1-6 , a processing equipment for cross-linked polyethylene insulated parallel bundled overhead cables, comprising a support base 3, a winding mechanism 7 is provided on one side of the top outer wall of the support base 3, and a chute 9 is provided on the top outer wall of the support base 3, and the sliding A slider 20 is slidably connected to the inner wall of the slot 9, an auxiliary mechanism 6 is arranged on the top outer wall of the slider 20, a moving mechanism 16 is arranged between the winding mechanism 7 and the auxiliary mechanism 6, and the moving mechanism 16 includes an air cushion 17 and an air bag 19, An air tube 18 is arranged between the air cushion 17 and the air bag 19. The air cushion 17 is located between the support base 3 and the winding mechanism 7, and the air bag 19 is located between the slider 20 and the chute 9. The air cushion 17 and the air bag 19 are both hollow elastic materials. When winding the cross-linked polyethyle...

Embodiment 2

[0036] refer to Figure 1-7 , a processing equipment for cross-linked polyethylene insulated parallel bundled overhead cables, comprising a support base 3, a winding mechanism 7 is provided on one side of the top outer wall of the support base 3, and a chute 9 is provided on the top outer wall of the support base 3, and the sliding A slider 20 is slidably connected to the inner wall of the slot 9, an auxiliary mechanism 6 is arranged on the top outer wall of the slider 20, a moving mechanism 16 is arranged between the winding mechanism 7 and the auxiliary mechanism 6, and the moving mechanism 16 includes an air cushion 17 and an air bag 19, An air tube 18 is arranged between the air cushion 17 and the air bag 19. The air cushion 17 is located between the support base 3 and the winding mechanism 7, and the air bag 19 is located between the slider 20 and the chute 9. The air cushion 17 and the air bag 19 are both hollow elastic materials. When winding the cross-linked polyethyle...

Embodiment 3

[0040] refer to Figure 1-8 , a processing equipment for cross-linked polyethylene insulated parallel bundled overhead cables, comprising a support base 3, a winding mechanism 7 is provided on one side of the top outer wall of the support base 3, and a chute 9 is provided on the top outer wall of the support base 3, and the sliding A slider 20 is slidably connected to the inner wall of the slot 9, an auxiliary mechanism 6 is arranged on the top outer wall of the slider 20, a moving mechanism 16 is arranged between the winding mechanism 7 and the auxiliary mechanism 6, and the moving mechanism 16 includes an air cushion 17 and an air bag 19, An air tube 18 is arranged between the air cushion 17 and the air bag 19. The air cushion 17 is located between the support base 3 and the winding mechanism 7, and the air bag 19 is located between the slider 20 and the chute 9. The air cushion 17 and the air bag 19 are both hollow elastic materials. When winding the cross-linked polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com