Mold cleaning process for mold production

A technology for molds and cleaning boxes, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of waste of water resources, uniform washing and cleaning of molds, and inability to filter and recycle sewage. Avoid wasting water resources, speed up filtration efficiency, and facilitate recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

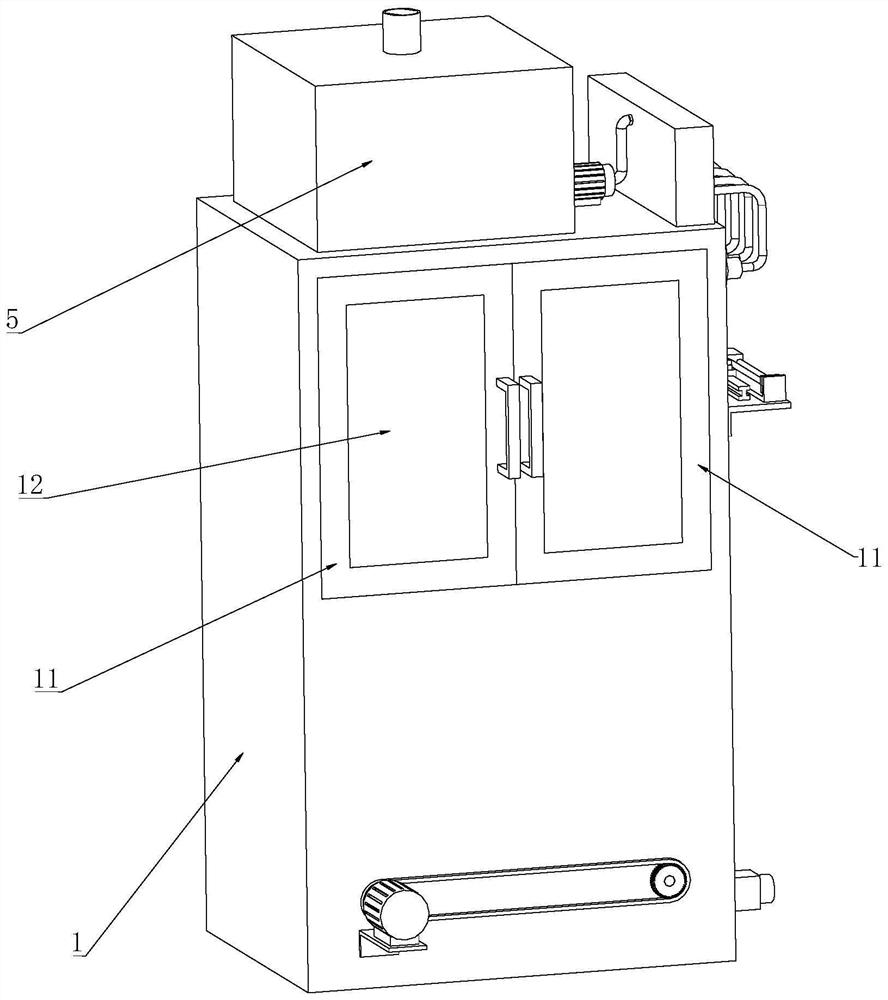

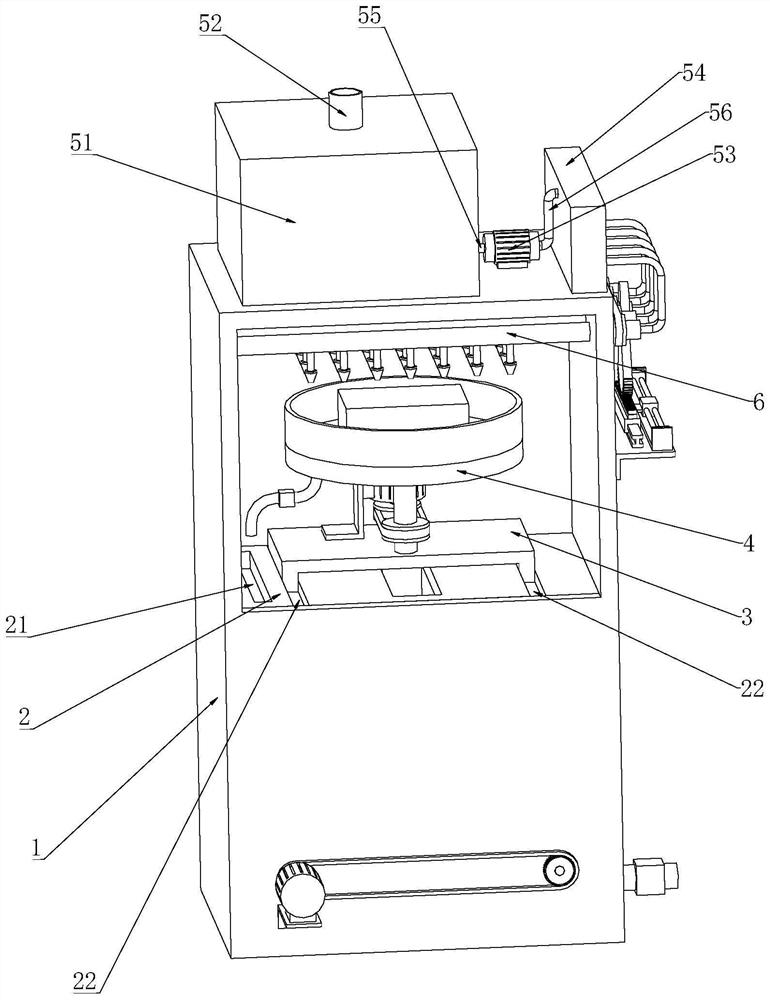

[0037] like Figure 1-7 As shown, a mold cleaning equipment for mold production includes a cleaning box 1, a partition plate 2, a moving frame 3, a mold carrying component 4, a water supply component 5, a spray component 6 and a filter component 7. The partition plate 2 Horizontally arranged in the cleaning box 1, two sliding doors 11 are hinged on the top outer wall of the cleaning box 1, a drainage groove 21 is arranged on one side edge of the dividing plate, and two symmetrically arranged tops of the dividing plate are provided. The moving frame 3 is slidably installed on the two sliding grooves 22, the mold bearing assembly 4 is installed on the top of the moving frame 3, the water supply assembly 5 is installed on the top of the cleaning box 1, the spraying The shower assembly 6 is installed at the inner top of the cleaning box 1, and the spray assembly 6 is communicated with the water supply assembly 5, and the filter assembly 7 is installed at the inner bottom end of th...

Embodiment 2

[0046] like image 3 As shown, a mold cleaning equipment for mold production is basically the same as that in Example 1. A horizontal plate 13 is horizontally arranged in the cleaning box 1. The horizontal plate 13 is located below the partition plate 2. The horizontal plate 13 A second screw slide table 14 is horizontally arranged on the top of the second screw slide table 14, a vertical plate 15 is arranged on the moving end of the second screw slide table 14, and the top of the vertical plate 15 is connected to the moving frame 3 through the partition plate 2, The partition plate 2 is provided with a rectangular slot 23 for the vertical plate 15 to pass through; the second screw slide 14 works to drive the vertical plate 15 and the moving frame 3 to move, and the moving frame 3 moves on the two chutes 22 to At the edge of the cleaning box 1 , the mold to be cleaned is placed in the shield 43 , and then the second screw slide 14 continues to work to drive the shield 43 to re...

Embodiment 3

[0048] The invention also discloses a cleaning process of the mold cleaning equipment for mold production, which comprises the following steps:

[0049]S1. Open the two sliding doors 11, the second screw slide table 14 works to drive the vertical plate 15 and the moving frame 3 to move, and the moving frame 3 moves on the two chutes 22 to the edge of the cleaning box 1, and the cleaning box 1 needs to be cleaned. The mold is placed in the shield 43, and then the second screw slide 14 continues to work to drive the shield 43 to reset;

[0050] S2, close the two sliding doors 11, the rotating motor 45 works to drive the rotating shaft 41 and the rotating disk 42 to rotate, the rotating disk 42 drives the mold in the shield 43 to rotate, and while the mold rotates, the water pump 53 works to extract the water in the water tank 51 It enters the transfer box 54 through the first water pipe 55 and the second water pipe 56, and then the water in the transfer box 54 enters the spray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com