Full-automatic steamed vermicelli roll machine

A sausage powder machine, a fully automatic technology, applied in the field of full-automatic sausage powder machine, can solve the problems of weight, thickness, size, difficulty in controlling intermittent pulp supply, poor product taste, etc., and achieve simple and controllable thickness and length, forming quality High and fast forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

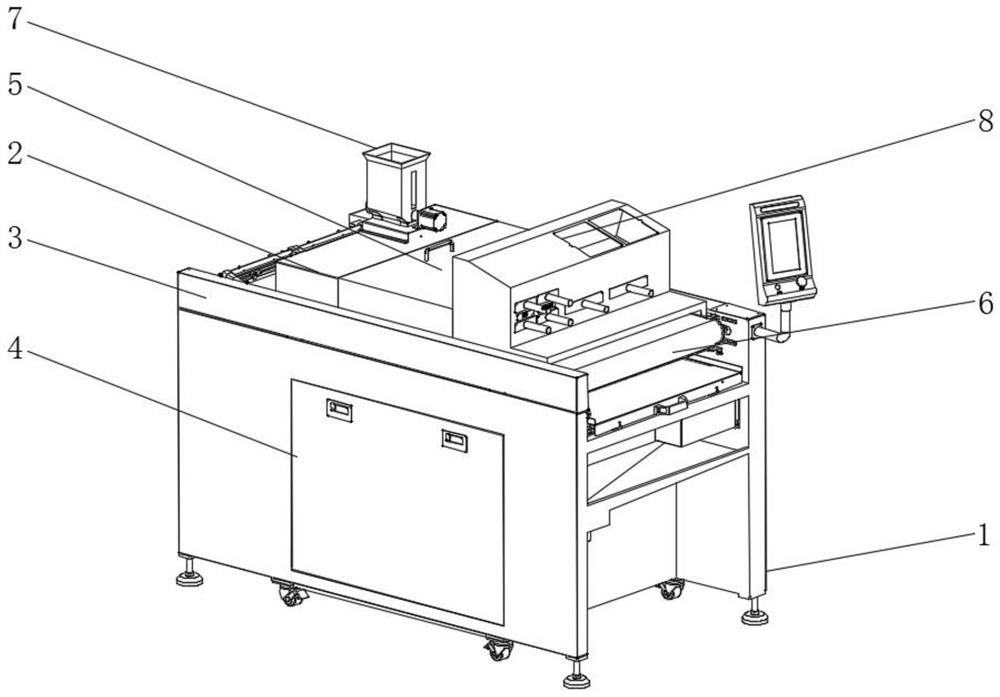

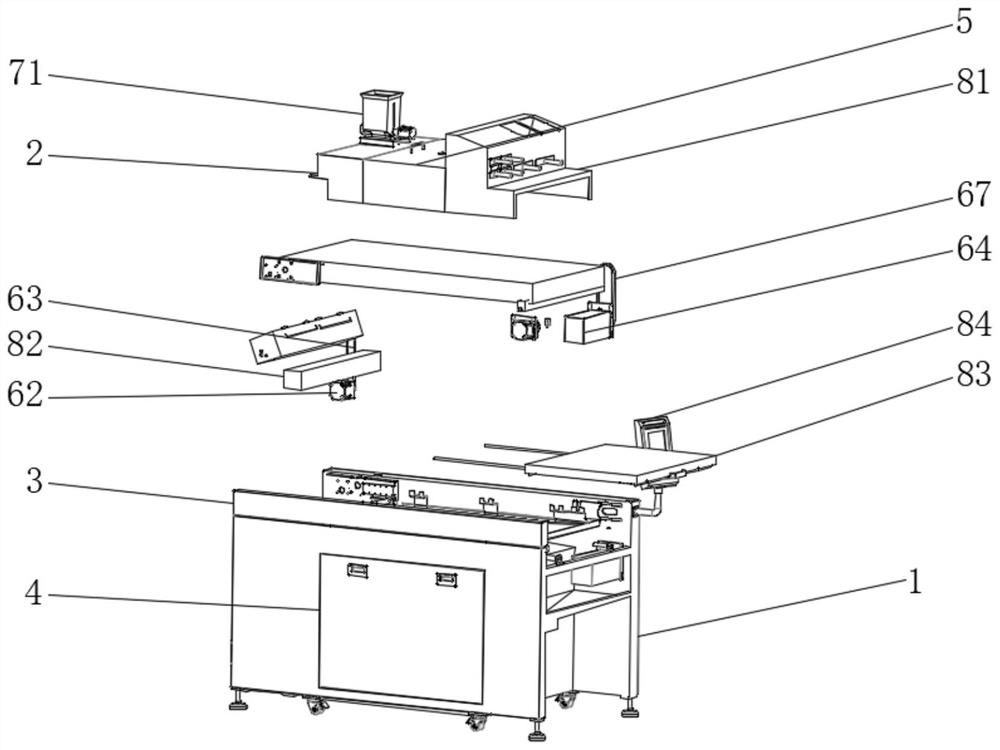

[0028] see Figure 1-5 , The present invention provides a technical solution: an automatic sausage powder machine, comprising a cabinet 1, the top of the cabinet 1 is connected with a support plate 2, the top of the cabinet 1 is movably connected with two overturning cleaning doors 3, and the front side of the cabinet 1 is provided There is a protective door 4, the protective door 4 is connected with the cabinet through hinges, the top of the cabinet 1 is fixedly connected with a frame plate 5, the frame plate 5 is arranged on the top of the cabinet 1, and a first feeding mechanism is rotatably connected to one side of the top of the cabinet 1 6. A second feeding mechanism 7 is fixedly connected to the top of the cabinet 1 , and a processing mechanism 8 is provided on the top of the cabinet 1 .

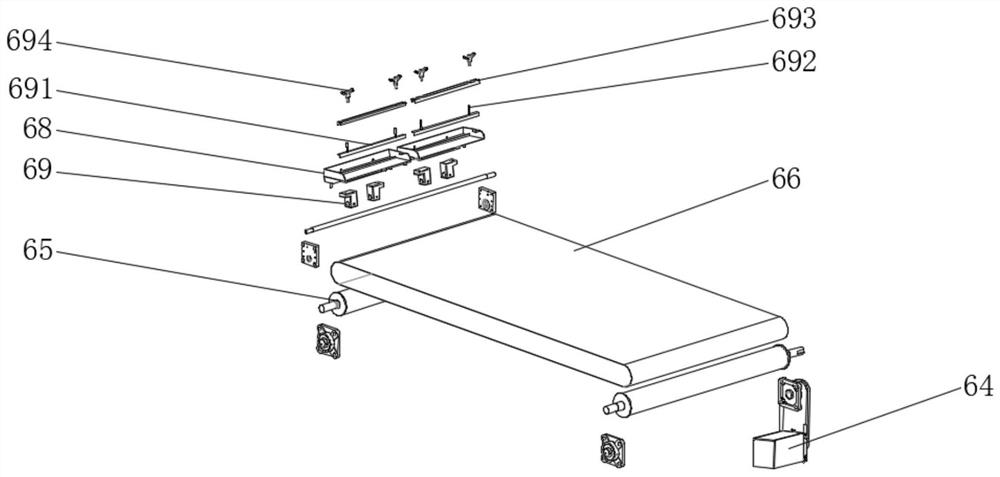

[0029] The first feeding mechanism 6 includes a rotating shaft 61. The rotating shaft 61 is arranged on the top of the two cabinet bodies 1 and is connected to the two cabinet bodies ...

Embodiment 2

[0032] see Figure 1-5 , and on the basis of Embodiment 1, it is further obtained that the second feeding mechanism 7 includes a slurry supply box 71, the slurry supply box 71 is arranged on the top of the support plate 2, the bottom of the slurry supply box 71 is fixedly connected with a base 72, and the base 72 is fixedly connected to The top of the cabinet 1, the top of the base 72 and the top of the support plate 2 are all provided with a feeding port 73. A third motor 74 is fixedly connected to one side of the pulp box 71, and the third motor 74 is fixedly connected to a threaded rod 75 through the output shaft. The rod 75 penetrates a side wall of the slurry supply box 71 and is connected with the slurry supply box 71 through a sealed bearing. A viewing port 76 is fixedly connected to one side of the slurry supply box 71. Two threaded blocks 77 are provided outside the threaded rod 75. The threaded rods 75 are Passing through two threaded blocks 77 and connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com