Preparation method and application of bioactive yoghourt for piglets

A bioactive, yogurt technology, applied in applications, animal feed, animal feed, etc., can solve the problems of insufficient milk for sows, irregular feeding and management, and difficulty in precise nutrition, so as to improve intestinal immunity and improve intestinal Health, relieve various stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

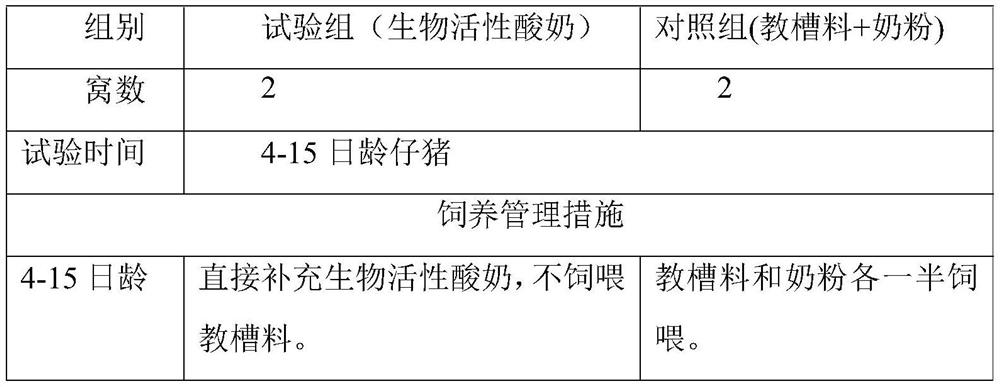

Image

Examples

Embodiment 1

[0049] Add water and stir, before heating up, put in 500U of saccharification enzyme by adding 400kg of basic rice flour, the ratio of material to water is 1:1, and stirring for 5min (stirring frequency 50r / min). The obtained mixture was heated (70° C.), and after the temperature was raised to the temperature, the enzymatic hydrolysis was carried out at a temperature of 40° C. according to the requirements of the process regulations, and the time was 50 minutes to obtain an enzymatic hydrolysis product. The obtained enzymatic hydrolysis product was cooled down, the stirring speed was adjusted to a predetermined value (50r / min), and the temperature was lowered to (25°C). Add a certain amount of dairy products (80kg whole milk powder) to the enzymatic hydrolysis solution after cooling, and then stir (20min) to obtain a mixed solution;

[0050] After the cooling and feeding is completed, the mixed liquid is divided into three parts, respectively entering three fermentation tanks,...

Embodiment 2

[0054] Add water and stir, before heating, put in 2000U of saccharifying enzyme by adding 300kg of basic rice flour, the ratio of material to water is 1:10, and stirring for 5min (stirring frequency 10r / min). The obtained mixture was heated up (130° C.), and after the temperature was raised to the temperature, the temperature was kept at 40° C. for enzymatic hydrolysis for 200 min to obtain an enzymatic hydrolysis product. The obtained enzymolysis product was cooled down, the stirring speed was adjusted to a predetermined value (10r / min), and the temperature was lowered to (45°C). Add a certain amount of dairy products (45kg whole milk powder and 45kg whey protein concentrate) to the enzymatic hydrolysis solution after cooling, and then stir (30min) to obtain a mixed solution;

[0055] After the cooling and feeding is completed, the mixed liquid is divided into three parts, respectively entering three fermentation tanks, fermentation tank A, fermentation tank B and fermentatio...

Embodiment 3

[0057] Add water and stir, before heating up, put in 1000U of saccharifying enzyme by adding 300kg of basic rice flour, the ratio of material to water is 1:5, and stirring for 5min (stirring frequency 10r / min). The obtained mixture was heated up (100° C.), and after the temperature was raised to the temperature, the temperature was kept at 40° C. for enzymatic hydrolysis for 130 min to obtain an enzymatic hydrolysis product. The obtained enzymolysis product was cooled down, the stirring speed was adjusted to a predetermined value (10r / min), and the temperature was lowered to (35°C). Add a certain amount of dairy products (75kg of whey protein concentrate) to the enzymatic hydrolysis solution after cooling, and then stir (30min) to obtain a mixed solution; after the cooling and feeding is completed, the mixed solution is divided into three parts, respectively entering 3 fermentation tanks, Fermentation tank A, fermentation tank B and fermentation tank C were respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com