Meat auxiliary processing equipment

An auxiliary processing and equipment technology, applied in meat processing equipment, meat cutting equipment, meat processing, etc., can solve the problems of uneven thickness of pig skin, irregular surface layout of pig skin, difficult cutting action of pig skin, etc. The effect of saving nitrogen resources and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

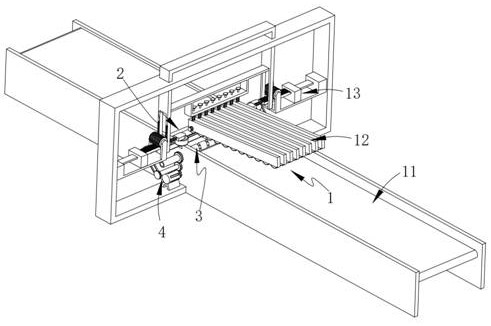

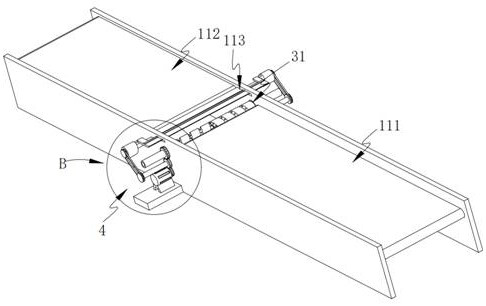

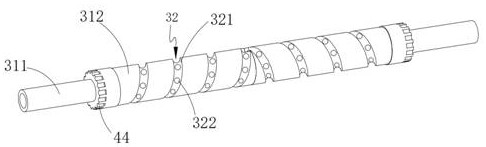

[0037] like figure 1 and 2 As shown in the figure, an auxiliary meat processing equipment is characterized in that it includes: a pressure feeding channel 1 for making the pig skin always face downward and outputting horizontally; a cutting assembly 2, the cutting assembly 2 for cutting meat skin is arranged in the One side of the pressure feeding channel 1; and a refrigeration assembly 3, the refrigeration assembly 3 is arranged under the cutting of the cutting assembly 2; the refrigeration assembly 3 includes: a refrigeration roller 31, which is used for positioning the cutting position of the pigskin. The cooling roller 31 is installed under the pressure feeding channel 1; the cooling roller 31 is provided with a spiral channel 32 for spraying liquid nitrogen to the meat skin and conveying the meat skin to both sides respectively.

[0038] It is not difficult to find from the above content that in the process of meat peeling, especially pork peeling, the pork skin is conve...

Embodiment 2

[0069] like figure 1 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0070] It also includes: a driving assembly 4 for driving the cutting assembly 2 to cut back and forth in the width direction of the meat skin, and to rotate the cooling roller 31 treated with nitrogen spray to pull the pig skin.

[0071] In this embodiment, when the refrigerating roller 31 rotates to pull the pigskin to both sides, by using the power of the driving component 4 to drive, the driving component 4 also drives the cutting component 2 to reciprocate left and right synchronously, so that the cooling roller 31 The refrigerated pigskin is cut.

[0072] It is worth noting that if Image 6As shown, the cutting assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com