Method for quickly and freely depositing or etching atomic layer and chamber structure

An atomic layer and chamber technology, applied in the field of method and chamber structure, fast and free deposition or etching of atomic layer, can solve the problems of slow growth or etching material rate, mutual contamination of precursor sources, etc., to improve deposition or Etching rate, avoiding cross-contamination, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the examples. The following examples are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

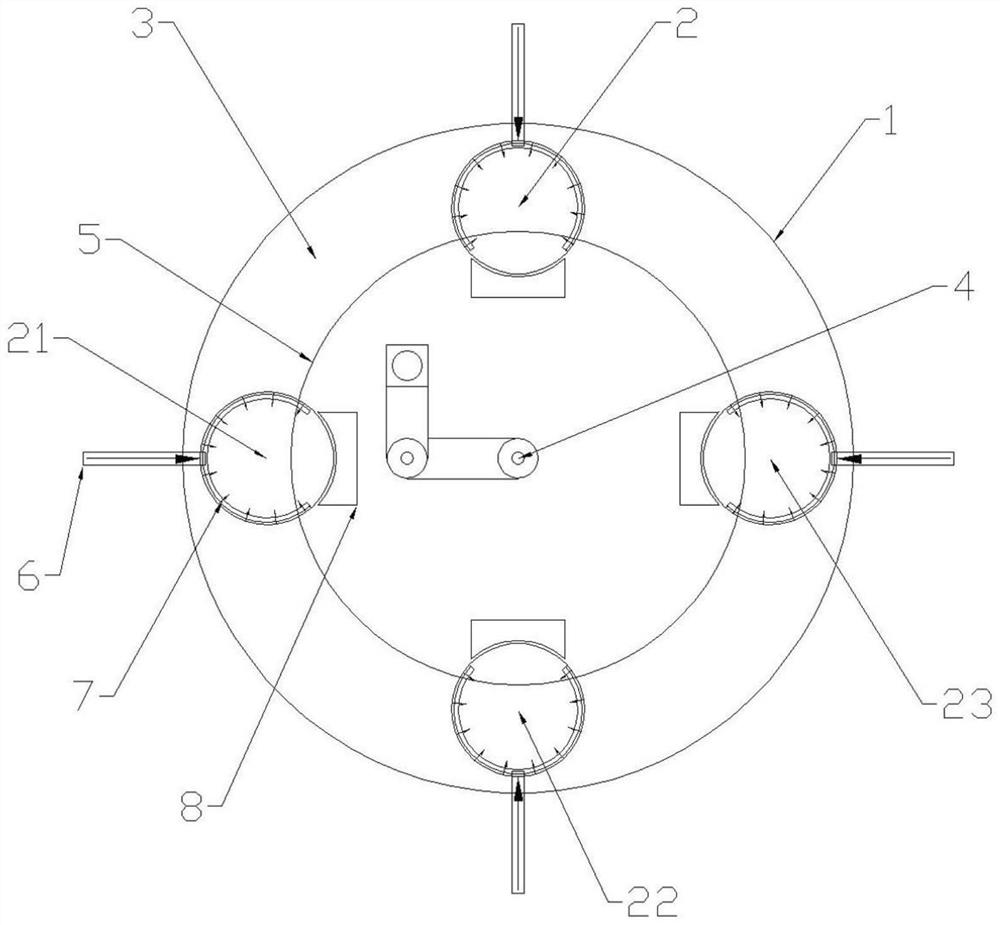

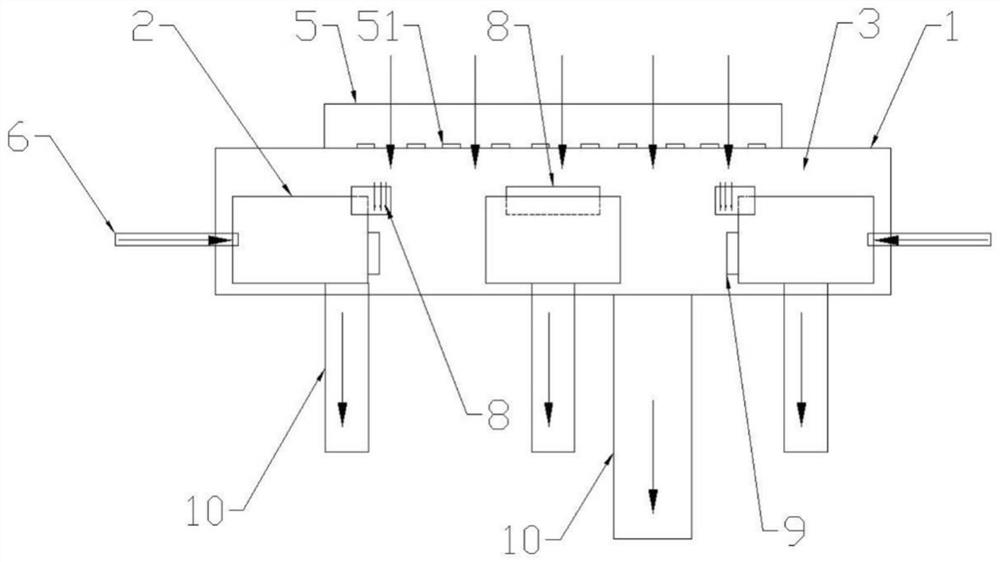

[0037] like Figure 1-6 As shown, a chamber structure for rapidly and freely depositing or etching atomic layers includes a disk chamber 1, and the disk chamber 1 is provided with a number of source reaction chambers 2 arranged in a circular ring. Chamber 2 provides the reaction place for the entire process, and each source reaction chamber 2 has only a single precursor source influx, which is carried by the carrier gas to avoid cross-infection of different precursor sources. The source reaction chamber 2 is outside the transmission chamber. 3;

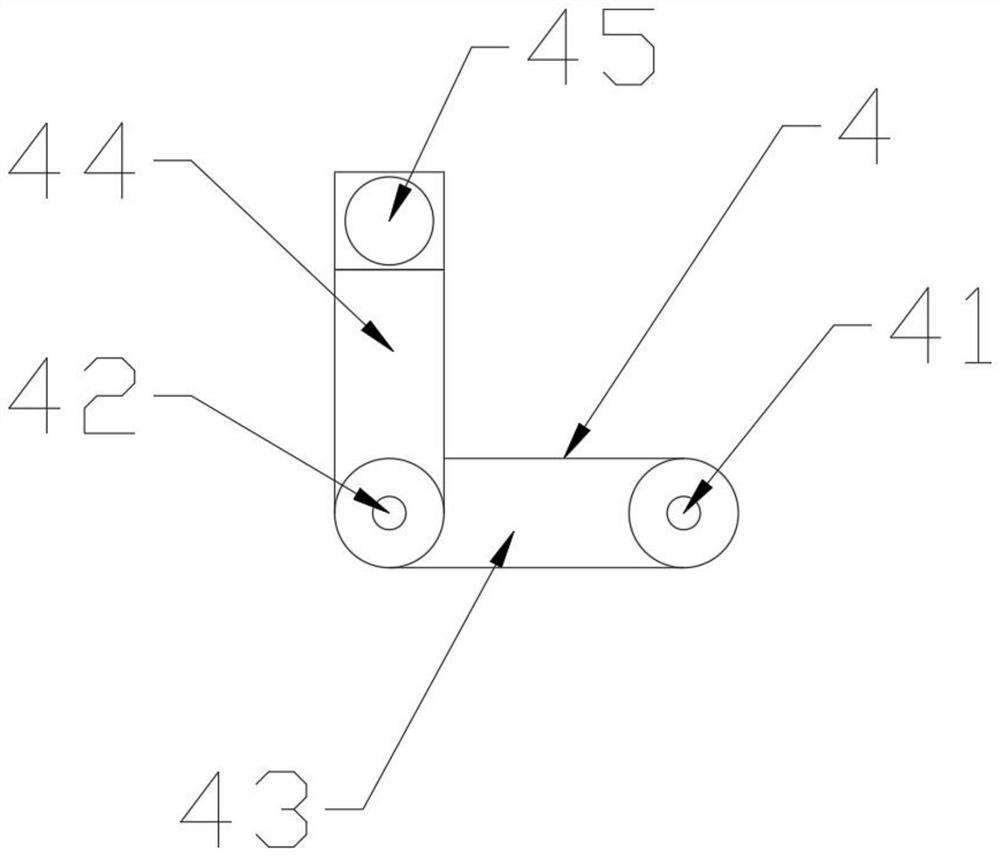

[0038] The middle of the disk chamber 1 is provided with at least one substrate transmission device 4 that rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com