Testing device and method under high-temperature and high-pressure hydrogen corrosion environment

A high-temperature, high-pressure, corrosive environment technology, applied in the direction of measuring devices, test sample preparation, weather resistance/light resistance/corrosion resistance, etc., to achieve stability and safety guarantee, good sealing performance, and avoid the effect of kettle lid wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the present invention, the present invention will be described below in conjunction with the embodiments. These descriptions are only used to further explain the features and advantages of the present invention, and are not intended to limit the claims of the present invention.

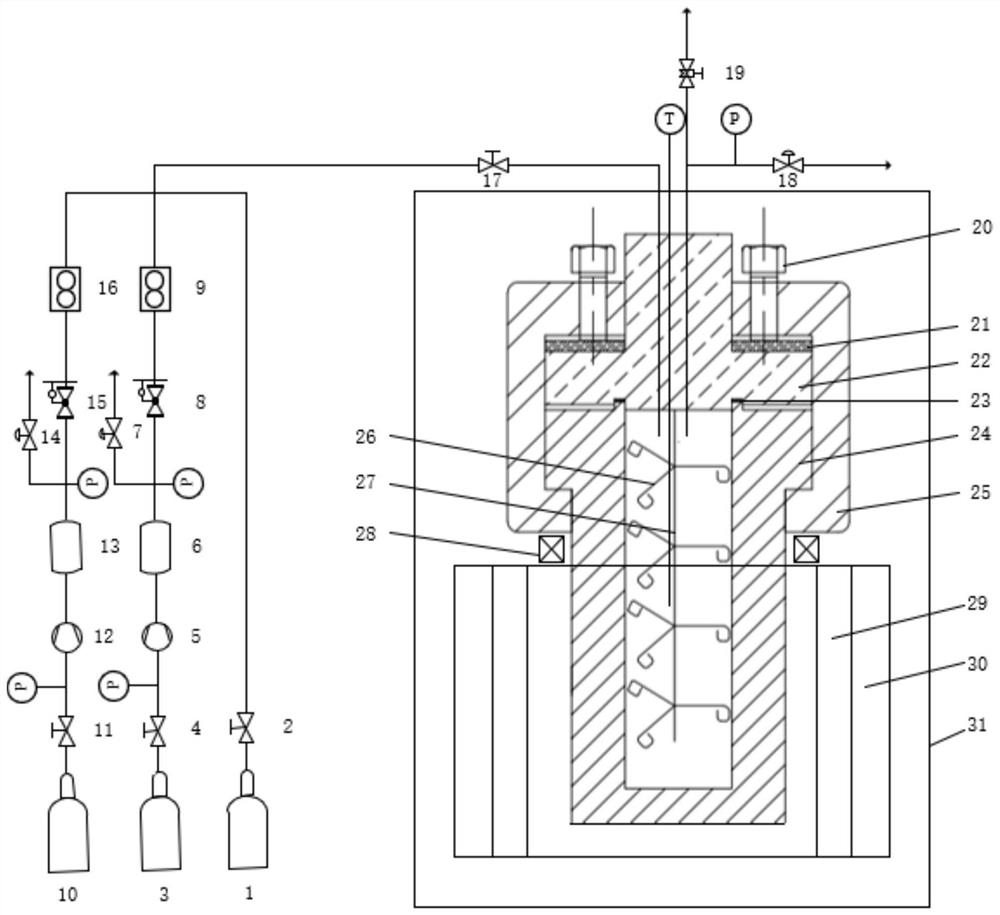

[0030] The testing device under the high temperature and high pressure hydrogen corrosion environment of the present invention includes: a main unit, a heating unit, a monitoring unit, an air supply unit, a fixing unit and a detection unit. The detailed schemes of each subunit are as follows.

[0031] Refer to the attached figure 1 , the main unit includes a high-temperature and high-pressure reaction kettle arranged in a vertical structure. The high-temperature and high-pressure reaction kettle includes a kettle cover 22, a kettle body 24 and a clamping plate 25. The upper end of the kettle cover 22 and the kettle body 24 is fixedly connected by the clamping plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com