Antibacterial slush molding skin for automobile instrument panel as well as preparation method and application of antibacterial slush molding skin

A technology for instrument panels and skins, applied in the field of antibacterial slush plastic skins and its preparation, can solve problems such as penetration into human skin, high price, secondary pollution, etc., and achieve high-efficiency, long-lasting antibacterial effects, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

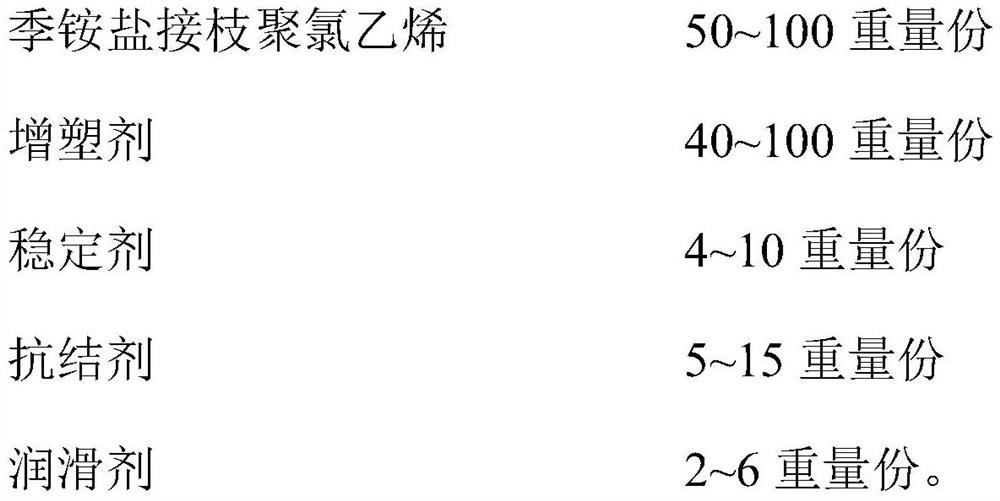

[0049] An antibacterial slush-molded skin for an automobile instrument panel, the material of which comprises the following components according to parts by weight:

[0050]

[0051] The preparation method of the antibacterial slush skin provided by the present embodiment comprises the following steps:

[0052] (1) 2kg polyvinyl chloride (Zhejiang Jin Lida, MG701-7AB2809) is added to the ethanol solution of 1% 3-chloropropyltriethoxysilane with 10kg mass percentage, and the pH value of the acetic acid adjustment system is 5. Mix for 2h under stirring conditions to obtain silane coupling agent modified polyvinyl chloride;

[0053] (2) 6L of acetonitrile was added to the 10L reaction kettle, then 2kg of the silane coupling agent-modified polyvinyl chloride obtained in step (1) and 6mol of dodecyl dimethyl tertiary amine were added, and the reaction was carried out at 50° C. for 72h to obtain Quaternary ammonium salt grafted polyvinyl chloride;

[0054] (3) quaternary ammoni...

Embodiment 2

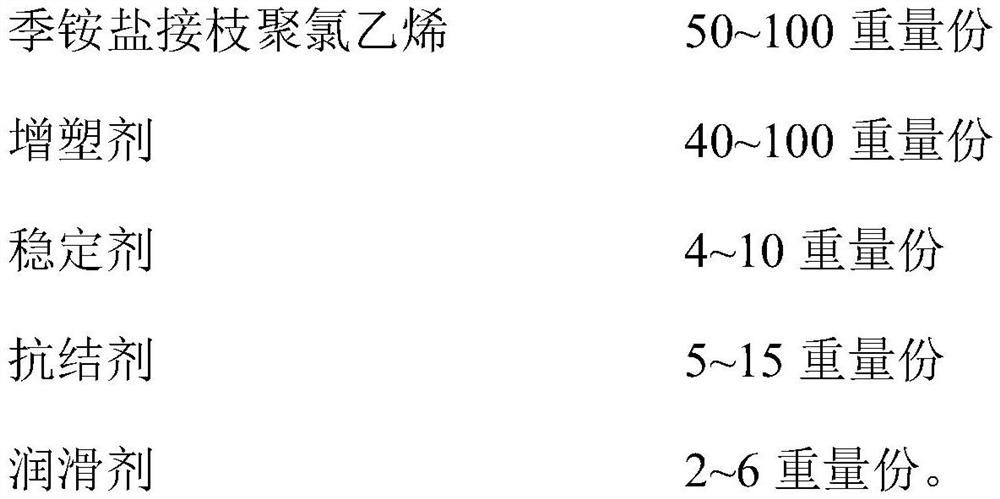

[0056] An antibacterial slush-molded skin for an automobile instrument panel, the material of which comprises the following components according to parts by weight:

[0057]

[0058]

[0059] The preparation method of the antibacterial slush skin provided by the present embodiment comprises the following steps:

[0060] (1) 2kg polyvinyl chloride (Zhejiang Jinlida, MG701-7AB2809) is added to the ethanol solution of 0.5% 3-chloropropyltriethoxysilane in 10kg mass percentage, and the pH value of the acetic acid adjustment system is 3.5, mixing under stirring conditions for 3 hours to obtain silane coupling agent modified polyvinyl chloride;

[0061] (2) 6L of acetonitrile was added to the 10L reactor, then 2kg of the silane coupling agent-modified polyvinyl chloride obtained in step (1) and 12mol of dodecyl dimethyl tertiary amine were added, and the reaction was carried out at 60° C. for 24h to obtain Quaternary ammonium salt grafted polyvinyl chloride;

[0062] (3) pou...

Embodiment 3

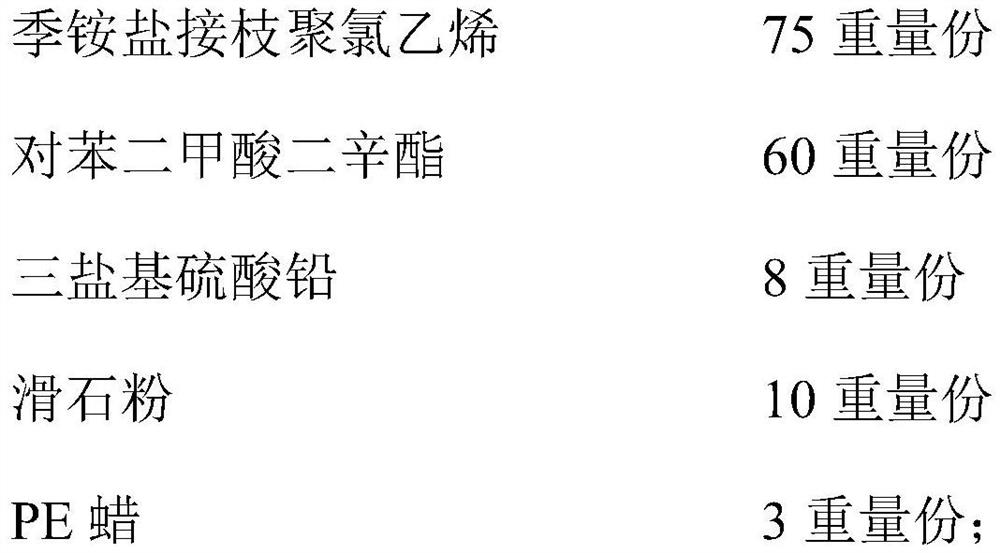

[0064] An antibacterial slush-molded skin for an automobile instrument panel, the material of which comprises the following components according to parts by weight:

[0065]

[0066] The preparation method of the antibacterial slush skin provided by the present embodiment comprises the following steps:

[0067] (1) 2kg polyvinyl chloride (Zhejiang Jin Lida, MG701-7AB2809) is added to the ethanol solution of 3% 3-chloropropyltriethoxysilane in 10kg mass percentage, and the pH value of adding acetic acid to adjust the system is 5. Mix for 2h under stirring conditions to obtain silane coupling agent modified polyvinyl chloride;

[0068] (2) 6L of acetonitrile was added to the 10L reactor, then 2kg of the silane coupling agent-modified polyvinyl chloride obtained in step (1) and 24mol of dodecyl dimethyl tertiary amine were added, and reacted at 50° C. for 24h to obtain Quaternary ammonium salt grafted polyvinyl chloride;

[0069] (3) pour the quaternary ammonium salt-grafted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com