Separation and purification process of by-product 2-butoxyethyl chloride in production process of tris (butoxyethyl) phosphate

A technology for the production process of butoxychloroethane, which is applied in the field of separation and purification of the by-product 2-butoxychloroethane, to achieve the effects of reducing pressure, difficult treatment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

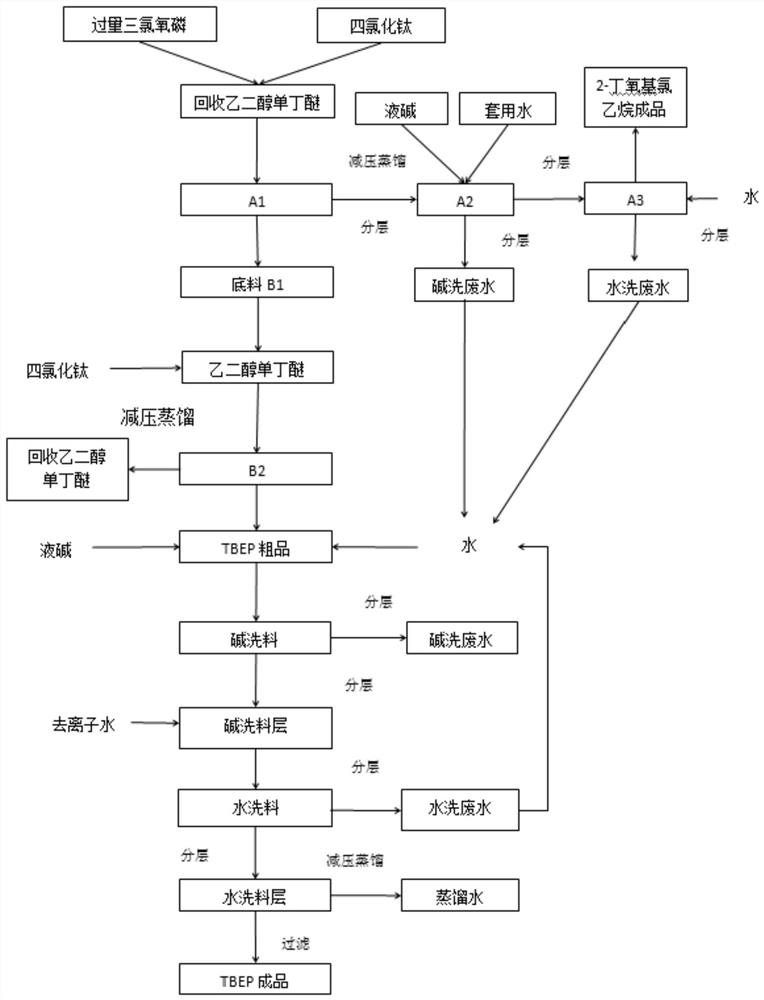

[0046] by e.g. figure 1 The flow shown is carried out.

[0047] 1) Esterification and dropwise addition of phosphorus oxychloride:

[0048] Take and recover 110g of ethylene glycol monobutyl ether and 0.3g of titanium tetrachloride, put it into a 500ml four-necked bottle, turn on stirring, keep the vacuum in the bottle at -0.094Mpa, and use an ice bath to cool down the bottom material to 10-15°C. , slowly drop 100.3g of phosphorus oxychloride into the bottom material, and the dropwise addition is completed in about 1.5h. The dropwise addition process needs to control the vacuum -0.094Mpa and the temperature of 15°C. After the dropwise addition, the temperature is maintained at 15°C for 1.5h;

[0049] 2) Esterification heat preservation:

[0050] Keeping the vacuum degree of the system unchanged, the temperature was raised to 50 °C and then kept for 1 h, sampling was carried out for gas chromatography to detect that there was no residue of ethylene glycol monobutyl ether, and i...

Embodiment 2

[0065] Other processes are consistent with embodiment 1, and embodiment 2 only proceeds to step (4), the difference is:

[0066] In step (1), the addition amount of phosphorus oxychloride was changed to 105.06g, and the addition amount of titanium tetrachloride was changed to 0.315g.

[0067] In step (3), the crude product A2 of 2-butoxychloroethane was distilled off and weighed 34.14 g, and gas chromatography detected: the purity of 2-butoxychloroethane was 96.65%, and the residual ethylene glycol monobutyl ether was 2.18%, Other components (phosphorus oxychloride, hydrogen chloride) 1.17%. Distillation bottoms B1 weighed 157.46 g.

[0068] In step (4), A2 alkali washing adds water 14.83g and the liquid caustic soda 2.24g of mass concentration 30%, washing adds water 17.07g, A2 after washing, sampling gas chromatography records 2-butoxychloroethane content 98.74%, Ethylene glycol monobutyl ether was 1.11%, and the water content was measured by Karl Fischer method to 0.15% t...

Embodiment 3

[0070] The other processes are the same as in Example 1, except that:

[0071] In step (1), the addition amount of phosphorus oxychloride was changed to 106.73g, and the addition amount of titanium tetrachloride was changed to 0.32g.

[0072] In step (3), the crude product A2 of 2-butoxychloroethane was distilled off and weighed 33.81 g, and gas chromatography detected: the purity of 2-butoxychloroethane was 97.61%, and the residual ethylene glycol monobutyl ether was 1.1%, Other components (phosphorus oxychloride, hydrogen chloride) 1.29%. Distillation bottoms B1 weighed 159.1 g.

[0073] In step (4), A2 alkali washing adds water 14.49g and the sodium hydroxide aqueous solution 2.42g of mass concentration 30%, washing adds water 16.9g, A2 after washing, sampling gas chromatography records 2-butoxychloroethane content 99.29 %, ethylene glycol monobutyl ether 0.56%, using Karl Fischer method to measure water content of 0.15% to obtain 33.24 g of 2-butoxychloroethane finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com