Double faced adhesive tape punching system

A double-sided tape, punching machine technology, applied in thin material handling, climate sustainability, final product manufacturing, etc., can solve problems such as low production efficiency and inconvenient operation, reduce manpower dependence, and improve stability. , the effect of improving the convenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

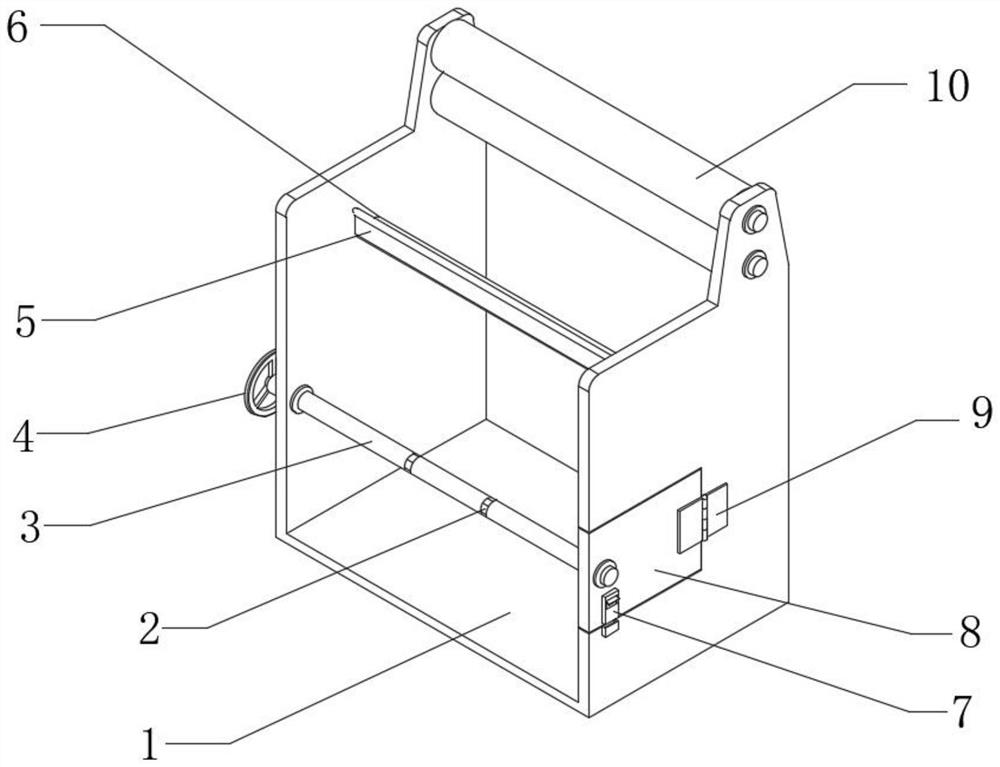

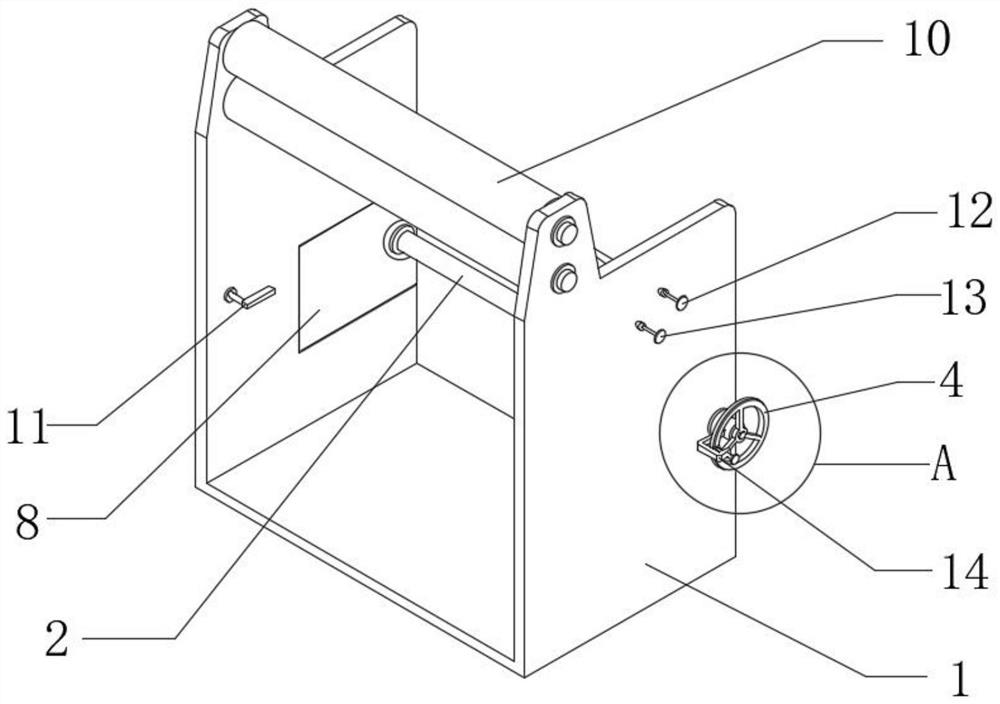

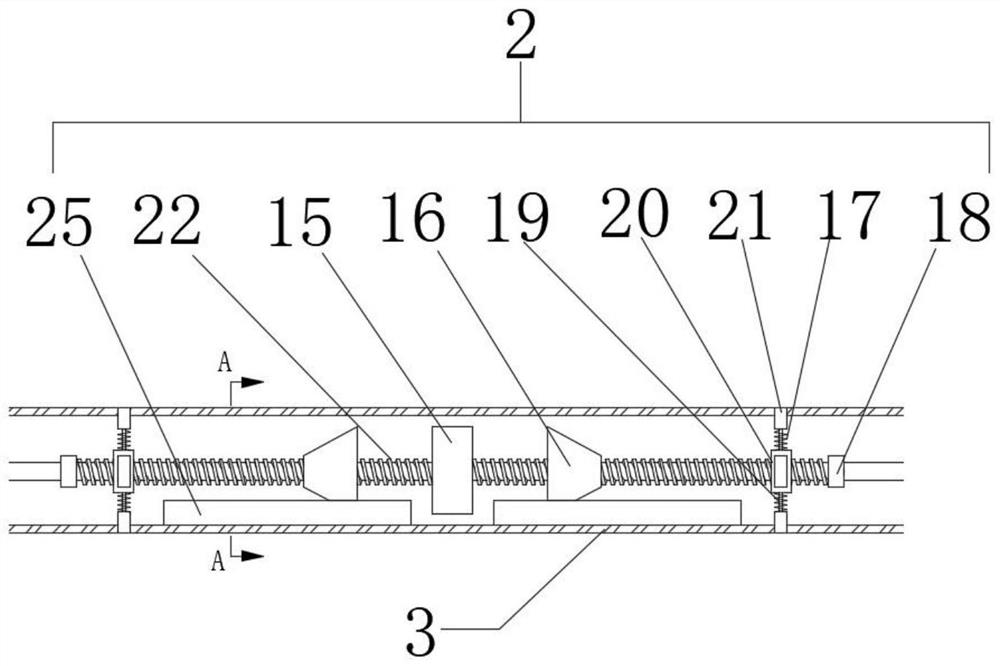

[0054] As an embodiment of the present invention, refer to figure 1 , image 3 and Image 6 , the feeding shaft 3 is provided with a built-in cavity, and the raw material fixing device 2 includes:

[0055] The screw 22, the screw 22 is fixedly installed on the feeding shaft 3, and the screw 22 passes through the built-in cavity;

[0056] The sliding table 25, two sliding tables 25 are symmetrically installed on the inner side wall of the feeding shaft 3, and the two sliding tables 25 are both provided with sliding grooves;

[0057] The round table 16 and the screw 22 are connected with two round tables 16 by a symmetrical screw drive, and the two round tables 16 are both provided with protruding blocks that cooperate with the chute on the sliding table 25;

[0058]The first limit block 15, the first limit block 15 is fixedly installed on the screw 22, and is located in the middle of the two circular platforms 16;

[0059] For the second limit block 18, two second limit blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com