Film sealing/packaging opening adopting pre-folding structure

A pre-folding and packaging technology, applied in the field of mechanical processing and manufacturing, can solve the problems of complex preparation process and high cost, and achieve the effect of simple process, low requirements for film materials, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

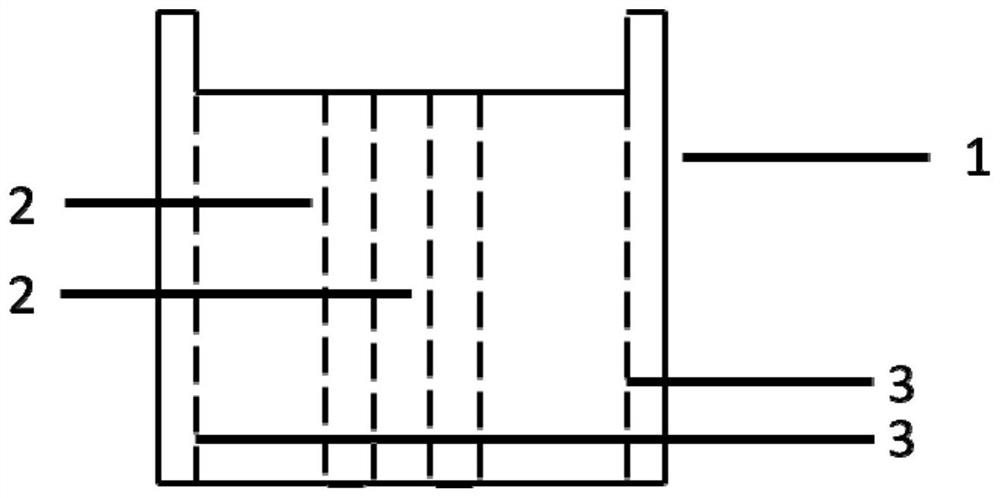

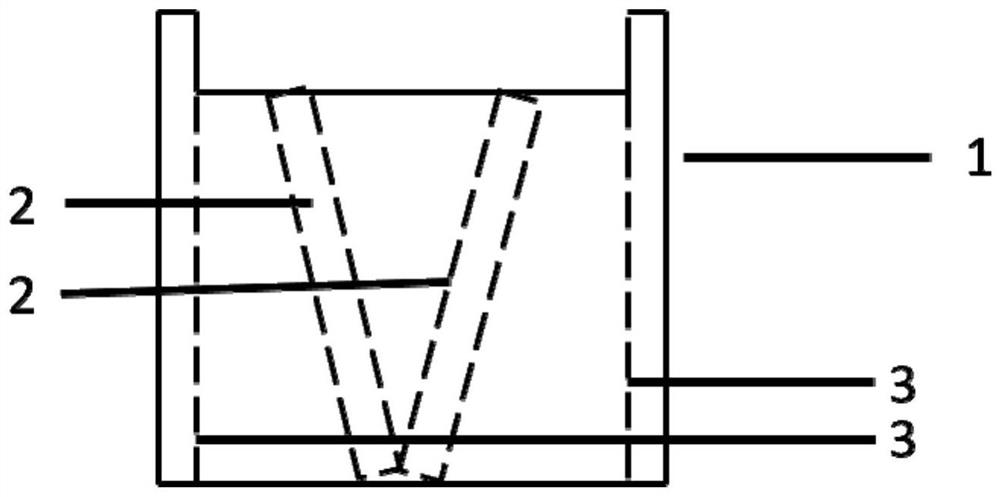

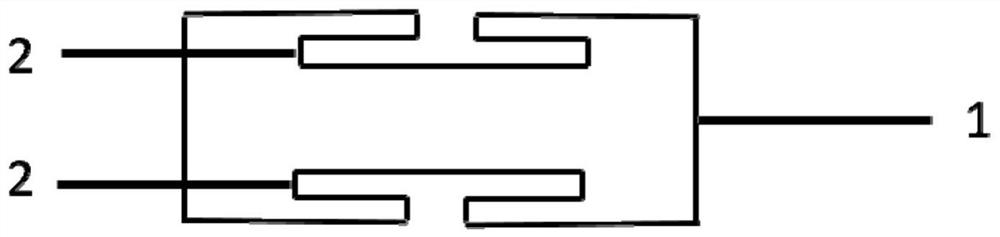

[0020] The embodiments of the present invention are described in detail below with reference to the technical solutions and the accompanying drawings.

[0021] As shown in the figure, the upper film and the lower film are folded separately during the preparation process; during use, by gently pulling the film on both sides of the sealing / packaging structure, the pre-folded structure produces friction / oscillation during the unfolding process and folding in the opposite direction. Marks facilitate quick opening of the seal / package opening. The pre-folded approach allows for quick opening of the film seal / wrap compared to conventional full fit film seals / wraps.

[0022] The film encapsulation / packaging structure can be an air-blown expandable film structure. Film structures with pre-folded creases are easier to deploy quickly than fully conformable expandable film structures.

[0023] The film seal / packaging opening can be a common plastic packaging bag in daily life. Conventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com