Method for preparing infusion bag by adopting biodegradable infusion bag special material

A technology of biodegradable and special materials, applied in the direction of biological packaging, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of non-degradable plastics, non-biodegradable, waste of resources, etc., and achieve good water vapor barrier Sexuality, prevention of proliferation, effects of addressing abuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

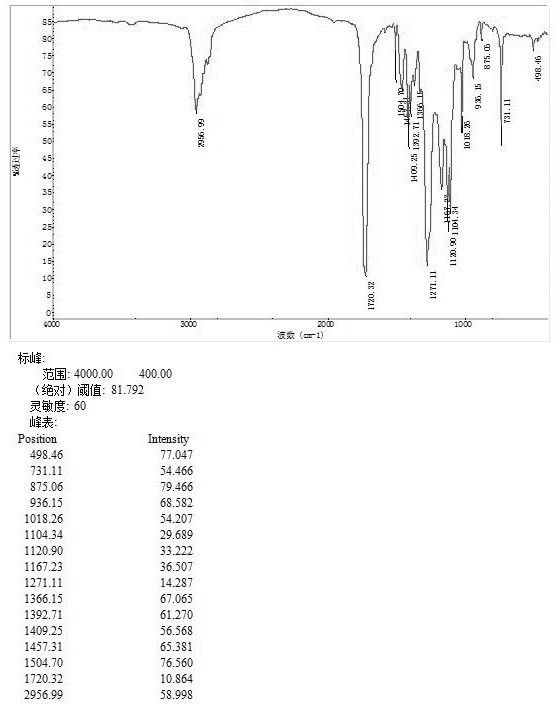

Image

Examples

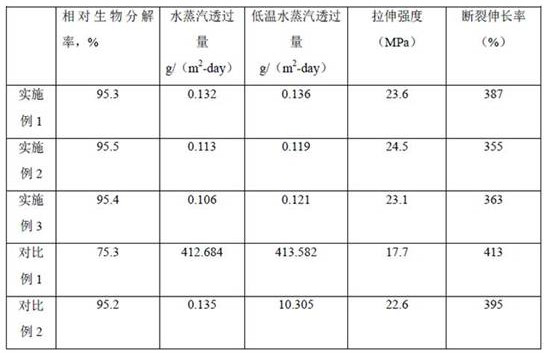

Embodiment 1

[0063] The special material for biodegradable infusion bag is composed of special material for inner layer, special material for middle layer and special material for outer layer, wherein:

[0064] The inner layer special material is made of the following raw materials by weight:

[0065] 90 servings of PBAT;

[0066]10 copies of PLA;

[0067] 1.1 parts of polycarbodiimide;

[0068] 1.0 part of talcum powder;

[0069] 3.5 parts of nano zinc oxide;

[0070] The special material for the middle layer is made of the following raw materials by weight:

[0071] 45 copies of PPC-TPU;

[0072] 54.2 copies of PPCP;

[0073] 0.8 servings of MDI;

[0074] The outer layer special material is made of the following raw materials by weight:

[0075] 100 copies of PBAT;

[0076] 0.5 part of polycarbodiimide;

[0077] Light stabilizer 944 0.4 parts;

[0078] Glyceryl tristearate 0.7 parts.

[0079] The proportions of the inner layer special material, the middle layer special materi...

Embodiment 2

[0091] The special material for biodegradable infusion bag is composed of special material for inner layer, special material for middle layer and special material for outer layer, wherein:

[0092] The inner layer special material is made of the following raw materials by weight:

[0093] 90 servings of PBAT;

[0094] 10 copies of PLA;

[0095] 0.8 part of polycarbodiimide;

[0096] 0.5 part of talcum powder;

[0097] 2.5 parts of nano zinc oxide;

[0098] The special material for the middle layer is made of the following raw materials by weight:

[0099] 30 copies of PPC-TPU;

[0100] 69.75 copies of PPCP;

[0101] 0.25 servings of MDI;

[0102] The outer layer special material is made of the following raw materials by weight:

[0103] 100 copies of PBAT;

[0104] 0.3 part of polycarbodiimide;

[0105] Light stabilizer 944 0.3 parts;

[0106] Glyceryl tristearate 0.5 part.

[0107] The proportions of the inner layer special material, the middle layer special mater...

Embodiment 3

[0119] The special material for biodegradable infusion bag is composed of special material for inner layer, special material for middle layer and special material for outer layer, wherein:

[0120] The inner layer special material is made of the following raw materials by weight:

[0121] 90 servings of PBAT;

[0122] 10 copies of PLA;

[0123] 1.5 parts of polycarbodiimide;

[0124] 1.5 parts of talcum powder;

[0125] 5.0 parts of nano zinc oxide;

[0126] The special material for the middle layer is made of the following raw materials by weight:

[0127] 60 copies of PPC-TPU;

[0128] 38.5 copies of PPCP;

[0129] 1.5 copies of MDI;

[0130] The outer layer special material is made of the following raw materials by weight:

[0131] 100 copies of PBAT;

[0132] 0.8 part of polycarbodiimide;

[0133] Light stabilizer 944 0.5 parts;

[0134] Glyceryl Tristearate 1.0 part.

[0135] The proportion of the inner layer special material, the middle layer special material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com