Safety needle group capable of being automatically sleeved with protective sleeve

A safety needle and sheath technology, used in needles, drug devices, and devices introduced into the body, etc., can solve problems such as needle stick injuries, staff infection, and missed needles, and achieve the effect of eliminating secondary use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

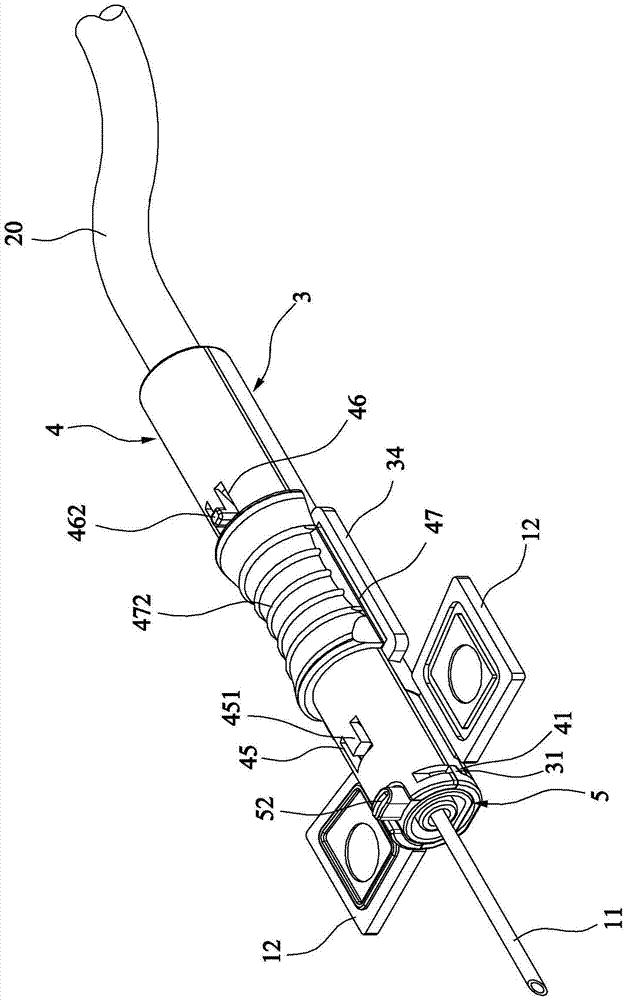

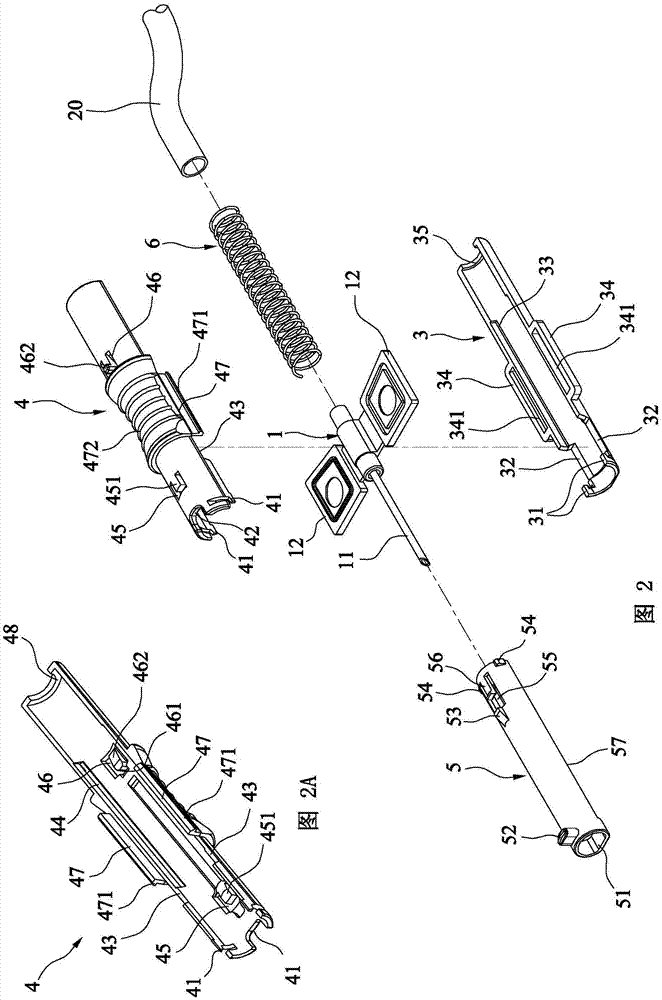

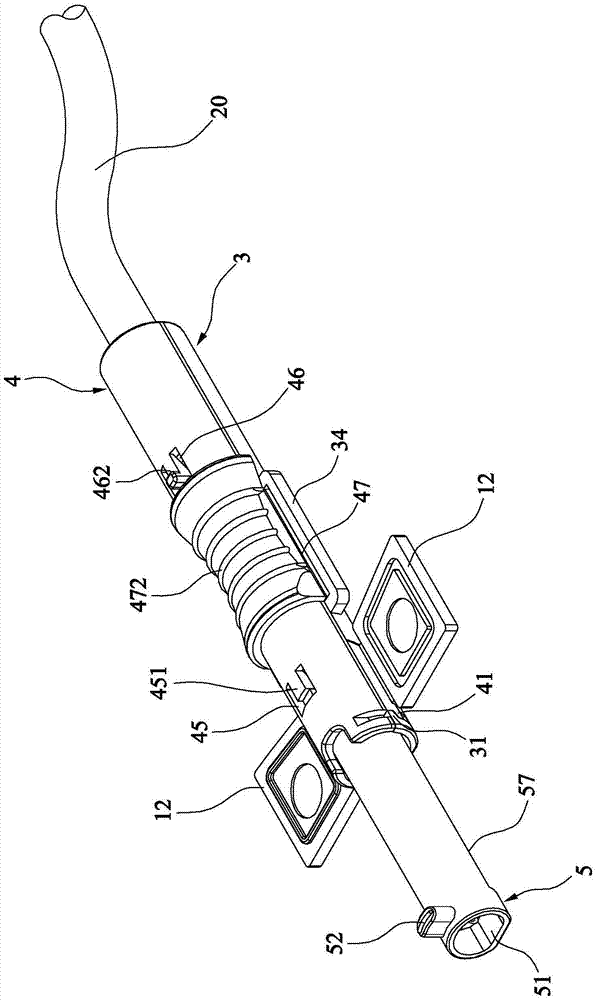

[0032] see figure 1 , FIG. 2 and FIG. 2A are perspective views and three-dimensional exploded schematic diagrams of the first embodiment of the safety needle set that can automatically fit the sheath according to the present invention. The safety needle set includes: a first needle assembly 1; a clamping lower seat 3; A clamp upper seat 4; a sheath 5 and a spring 6.

[0033] One end of the first needle assembly 1 is a needle head 11 with a needle head, and a wing 12 is connected to each side of the needle head 11. Before the needle head 11 is not used, a protective sleeve (not shown) is used to cover the needle head. , and the other end of the first needle assembly 1 is sleeved and connected with a medical fluid conduit 20 .

[0034] The lower group of the first needle assembly 1 is provided with a clamping lower seat 3 , and corresponding to the clamping lower seat 3 is provided with a clamping upper seat 4 , and the corresponding group of the clamping upper seat 4 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com