Pressure-sensitive pasting device for pressure-sensitive adhesive tape production line

A technology of pressure-sensitive adhesive tape and sticking device, which is applied to devices for coating liquid on surfaces, coatings, pre-treatment surfaces, etc. Uniform gluing and firm pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

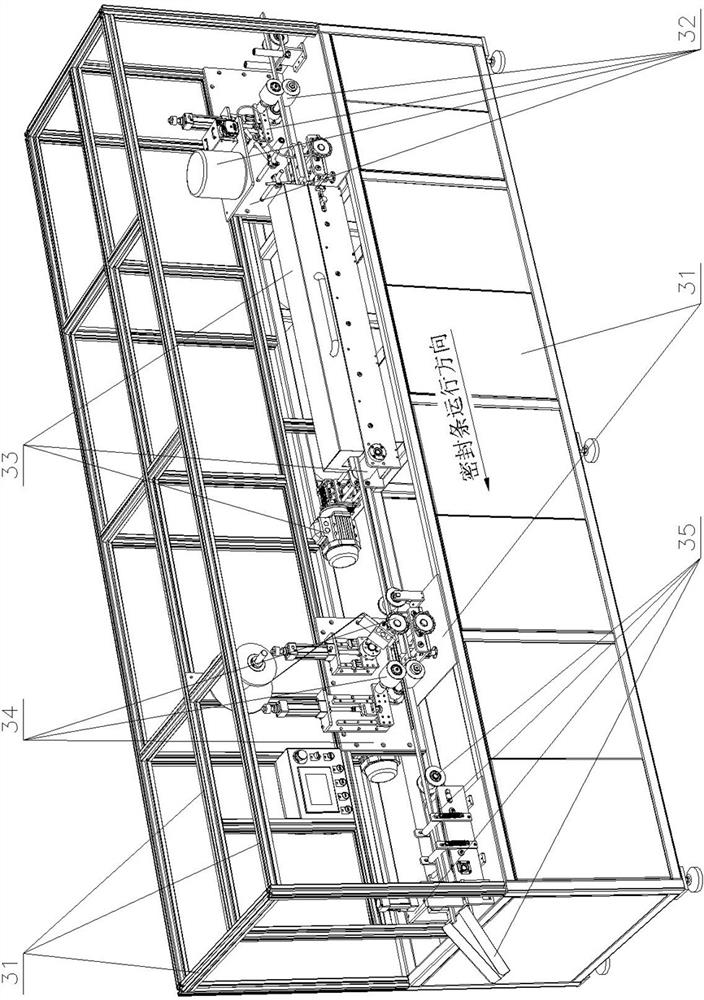

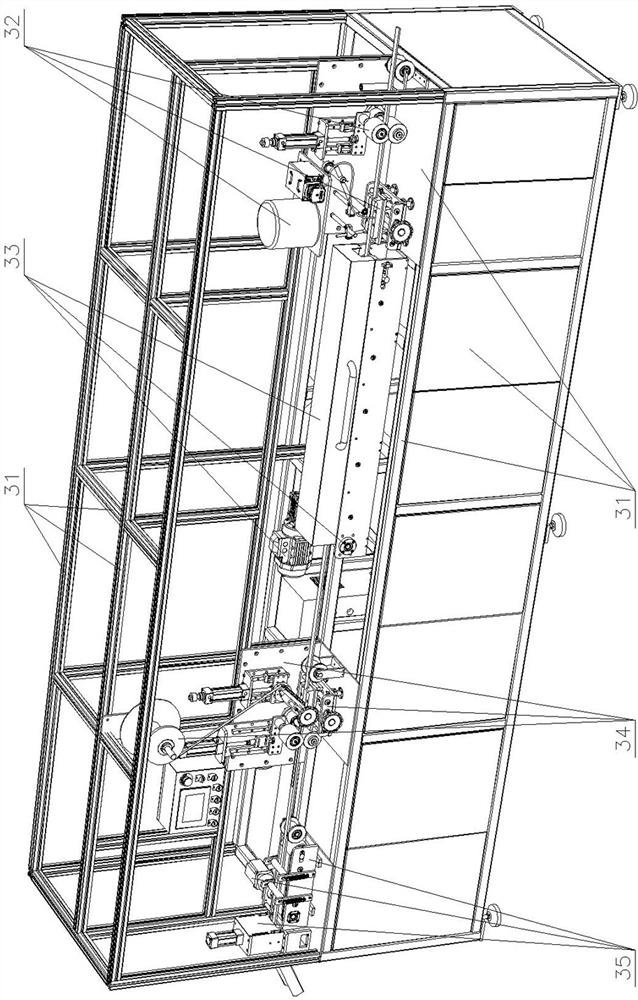

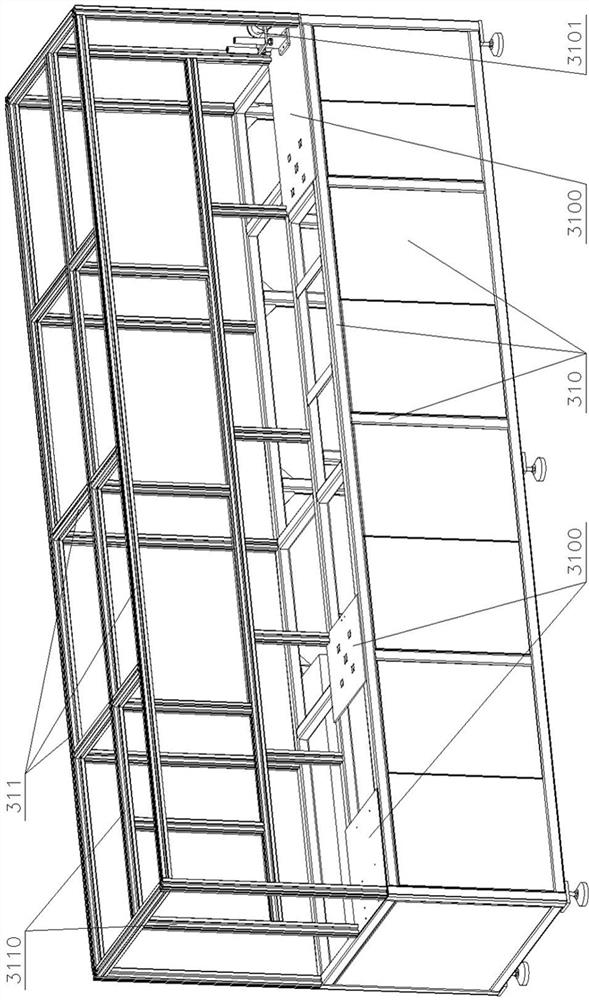

[0039]31. Pressure-sensitive workbench 310, pressure-sensitive 6-sided box 3100, pressure-sensitive platen 3101, pressure-sensitive guide frame 311, pressure-sensitive 6-sided frame 3110, middle plane rectangular frame 32, gluing device 320, gluing guide device 3200 , glued traction assembly 32000, glued base plate 32001, pressure-sensitive traction drive 32002, pressure-sensitive active roller 32003, pressure-sensitive cylinder 32004, pressure-sensitive guide rail 32005, pressure-sensitive roller mounting plate 32006, pressure-sensitive slider 32007, pressure-sensitive pressure roller 3201, gluing support assembly 32010, gluing rod 32011, pressing roller 32012, gluing tension spring 32013, conduit nozzle 32014 gluing brush 321, glue dispensing assembly 3210, glue plate 3211, glue pump 3212, glue bucket 3213, drip hose 322, pressure sensitive mold assembly 3220, mold U-shaped frame 3221, mold guide post 3222, mold round nut 3223, mold screw 3224, mold hand wheel 3225, mold guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com