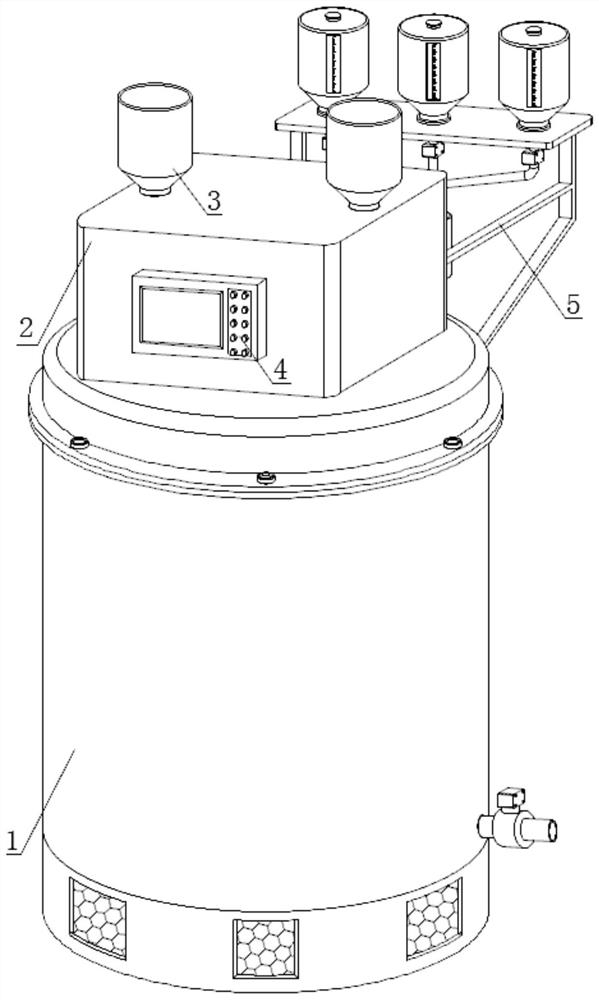

Raw material premixing equipment and method capable of regularly filling reactants for plastic products

A technology for plastic products and reactants, which is applied to the field of raw material premixing equipment for regularly adding reactants, can solve the problems of affecting the mixing effect, poor raw material processing effect, and inaccurate control of the adding time of the reactants, so as to avoid the time effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

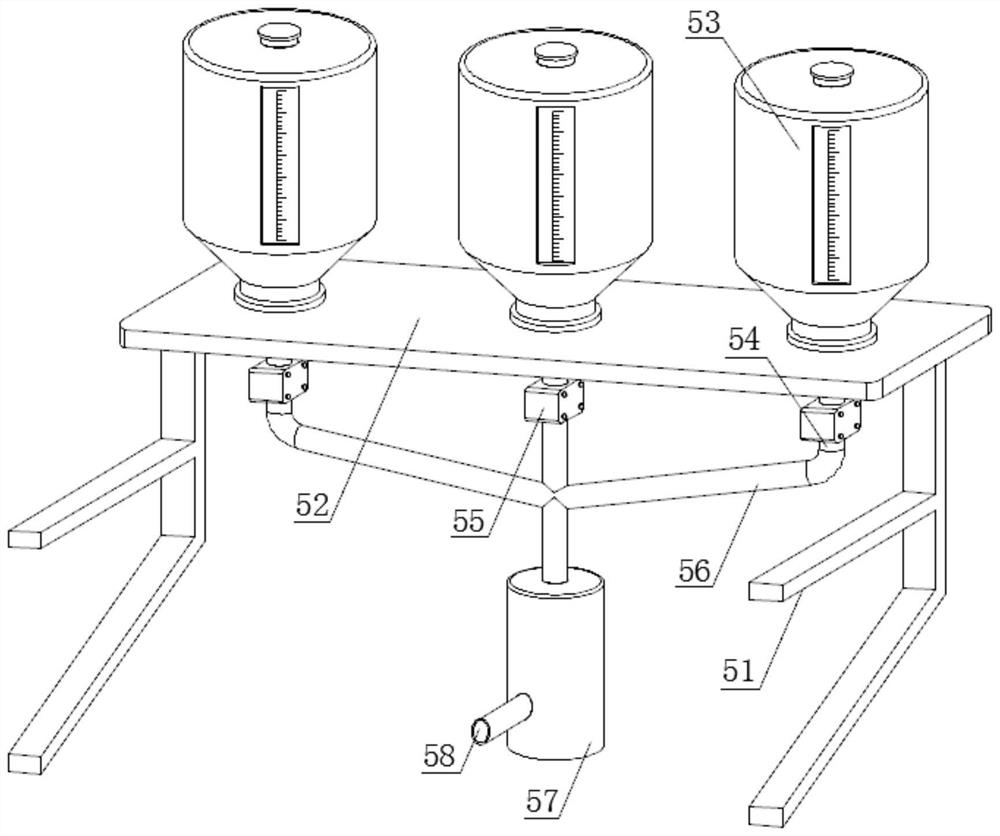

[0057] In order to better demonstrate the raw material premixing equipment used for plastic products that can add reactants regularly, this embodiment provides an implementation method of the raw material premixing equipment that can add reactants regularly for plastic products, including the following steps:

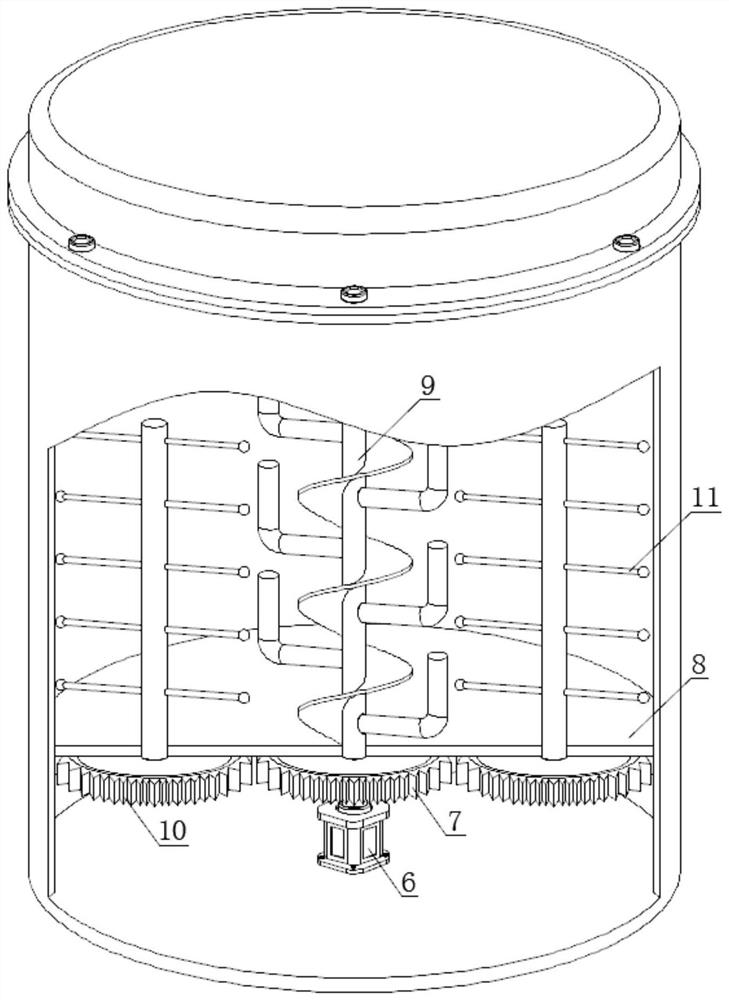

[0058] Step 1: Put different plastic raw materials into the feeding hopper 3, the plastic raw materials enter the mixing treatment box 2 from different feeding hoppers 3, and the plastic raw materials follow the opposite materials on the inner wall of the mixing treatment box 2. The inclined plate 21 slides down, and the raw material slides down to the bottom of the receiving inclined plate 21 and jumps up under the action of the throwing guide table 22 to perform flat throwing and mixing;

[0059] Step 2: then start the stirring motor 6 to drive the stirring rod 9 to rotate, the stirring rod 9 drives the adjusting cam 259 to rotate through the connecting rod 258, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com