Method for preparing spherical Cu/Fe biochar composite material by one-step method and application of spherical Cu/Fe biochar composite material

A composite material, biochar technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve problems such as the cost of raw materials for major secondary pollutants, achieve strong antioxidant capacity and reduce production costs. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

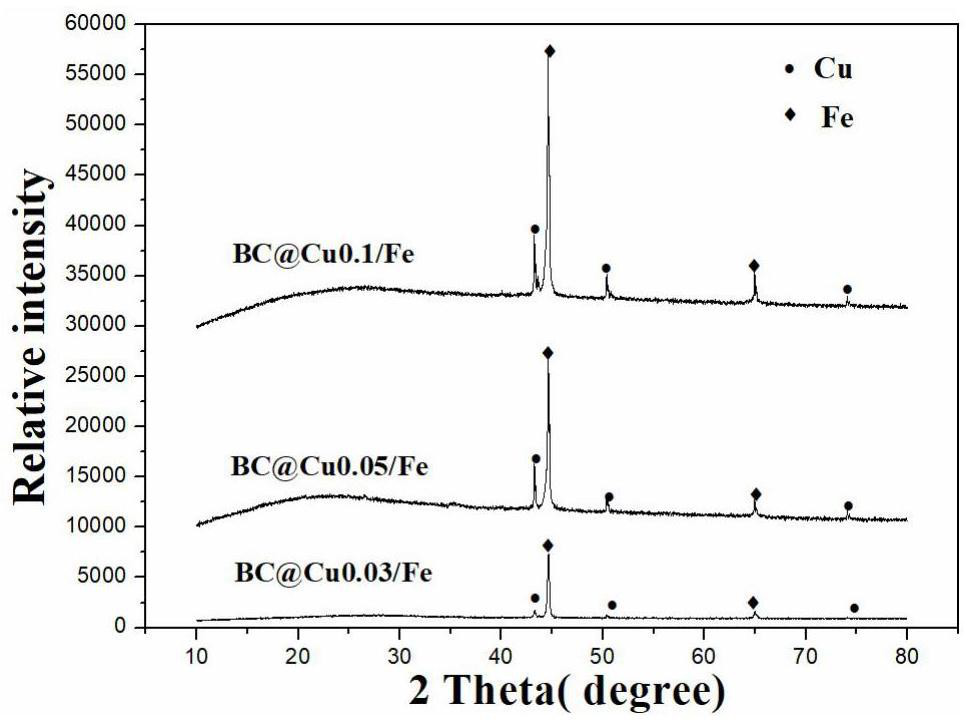

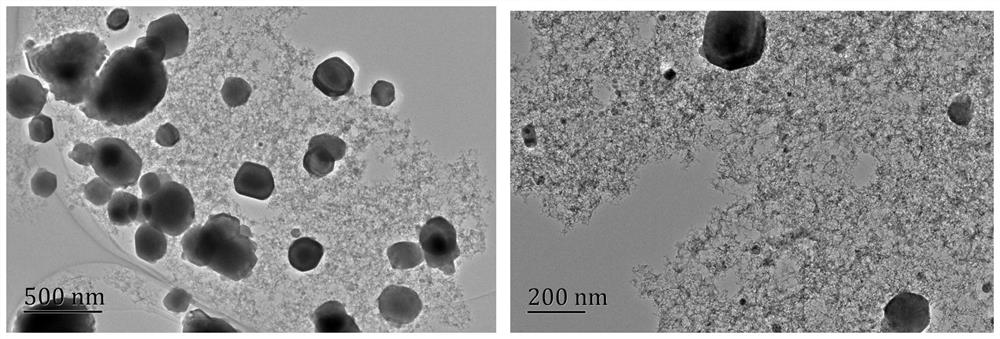

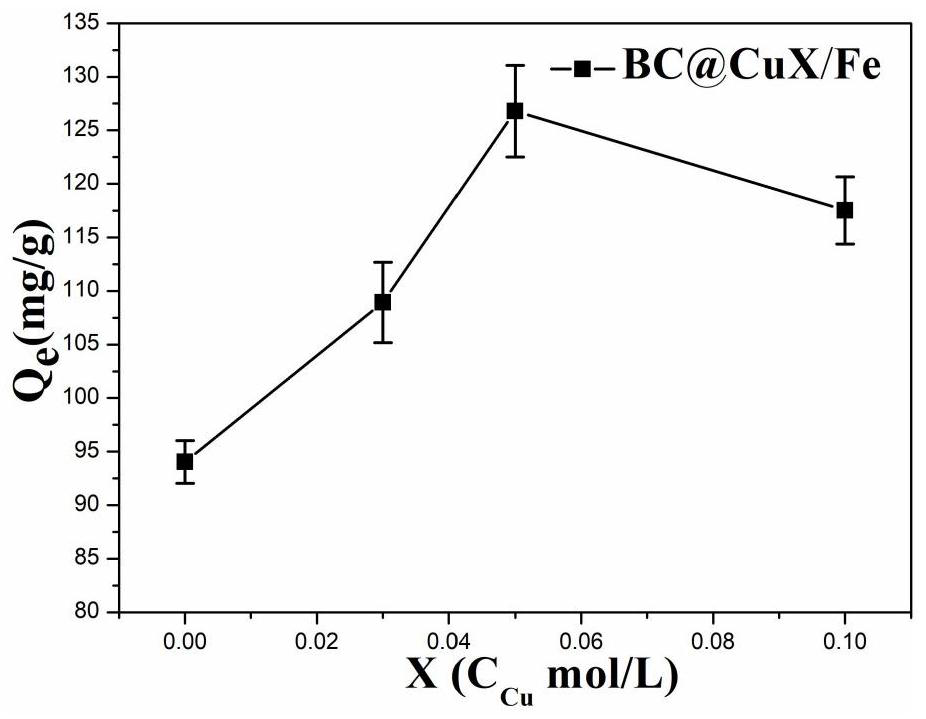

Embodiment 1

[0024] Take 30 g of sodium algina and place it in a cup, add 1L distilled water to stir and dissolve, and make sodium alginate solution. Formation FeCL 3 · 6H 2 O material concentration is 0.3 mol / L; configure CUCL 2 The amount of material is 0.03mol / L, and feed 3 · 6H 2 O solution and cUCL 2 The solution is mixed with a hybrid solution. Drop the sodium alginate solution into the mixed solution, the cross-linking of the solution, and the rest of 24h, and the alginic acid -FE 3+ / Cu 2+ Gel, wash 6 times with distilled water, dry at 60 ° C in vacuum drying oven, and then dry 3h at 100 ° C. 3+ / Cu 2+ gel. Alotide-FE after drying 3+ / Cu 2+ After the gel is vacuumed for 15min, it is 20min at a high level of high -purity nitrogen at a rate of 200ml / min; then at the condition of 100ml / min nitrogen flow rate, at a heating rate of 5 ℃ / min to heating to 200 ° C, and then at 10 ° C / min The heating speed is heated to 900 ° C, and after 3H at 900 ° C, it is cooled to room temperature at a cool...

Embodiment 2

[0027] Take 30 g of sodium algina and place it in a cup, add 1L distilled water to stir and dissolve, and make sodium alginate solution. Formation FeCL 3 · 6H 2 O material concentration is 0.3 mol / L; configure CUCL 2 The quantity concentration of the material is 0.05mol / L. FECL will 3 · 6H 2 O solution and cUCL 2 The solution is mixed with a hybrid solution. Drop the sodium alginate solution into the mixed solution, the cross-linking of the solution, and the rest of 24h, and the alginic acid -FE 3+ / Cu 2+ Gel, wash 7 times with distilled water, dry at 60 ° C in vacuum drying oven, and then dry 3h at 100 ° C. 3+ / Cu 2+ gel. Alotide-FE after drying 3+ / Cu 2+ After the gel is vacuumed for 15min, it is 20min at a high level of high -purity nitrogen at a rate of 200ml / min; then at the condition of 100ml / min nitrogen flow rate, at a heating rate of 5 ℃ / min to heating to 200 ° C, and then at 10 ° C / min The heating speed is heated to 900 ° C, and after 3H at 900 ° C, it is cooled to room ...

Embodiment 3

[0031] Take 30 g of sodium algina and place it in a cup, add 1L distilled water to stir and dissolve, and make sodium alginate solution. Formation FeCL 3 · 6H 2 O material concentration is 0.3 mol / L; configure CUCL 2 The quantity concentration of the material is 0.1mol / L. FECL will 3 · 6H 2 O solution and cUCL 2 The solution is mixed with a hybrid solution. Drop the sodium alginate solution into the mixed solution, the cross-linking of the solution, and the rest of 24h, and the alginic acid -FE 3+ / Cu 2+ Gel, wash 8 times with distilled water, dry at 60 ° C in vacuum drying oven, and then dry 3h at 100 ° C. 3+ / Cu 2+ gel. Alotide-FE after drying 3+ / Cu 2+ After the gel is vacuumed for 15min, it is 20min at a high level of high -purity nitrogen at a rate of 200ml / min; then at the condition of 100ml / min nitrogen flow rate, at a heating rate of 5 ℃ / min to heating to 200 ° C, and then at 10 ° C / min The heating speed is heated to 900 ° C, and after 3H at 900 ° C, it is cooled to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com