Embedded stranding machine with compact structure

A compact structure and stranding machine technology, which is applied in thin material processing, electrical components, cable/conductor manufacturing, etc., can solve the problems of large equipment footprint, waste of factory space, and complex structure, etc., to reduce the footprint, Improving utilization rate, streamlining and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

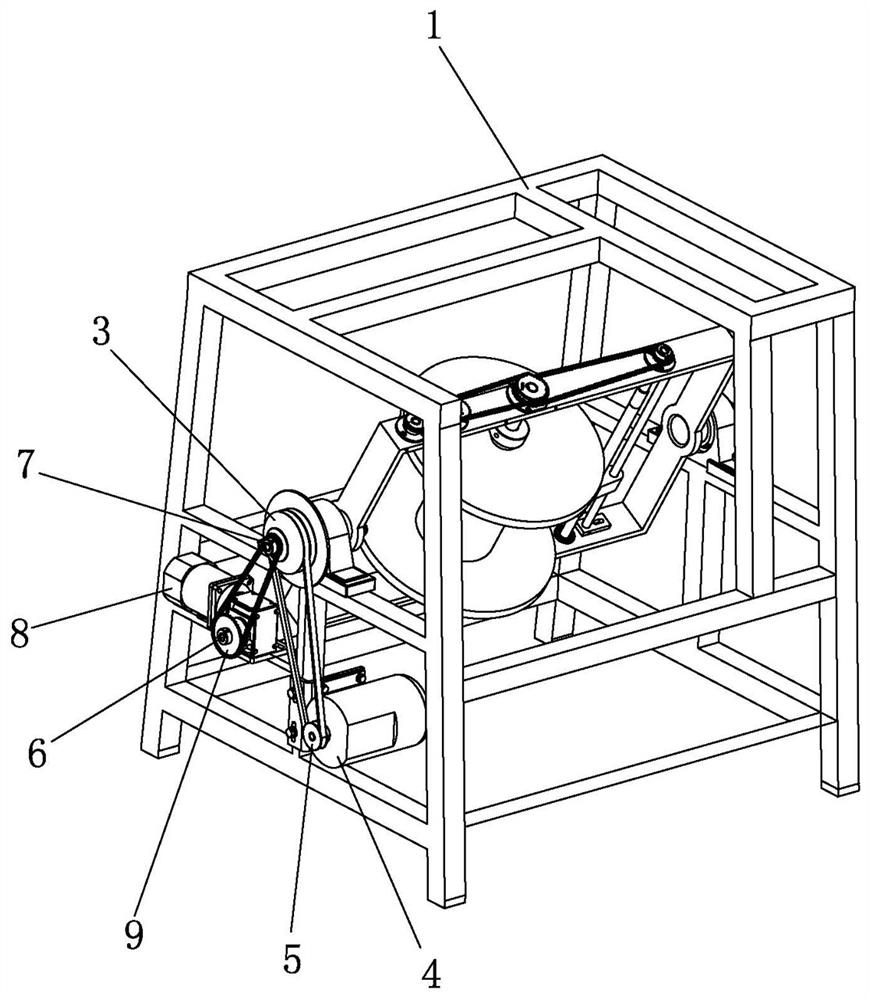

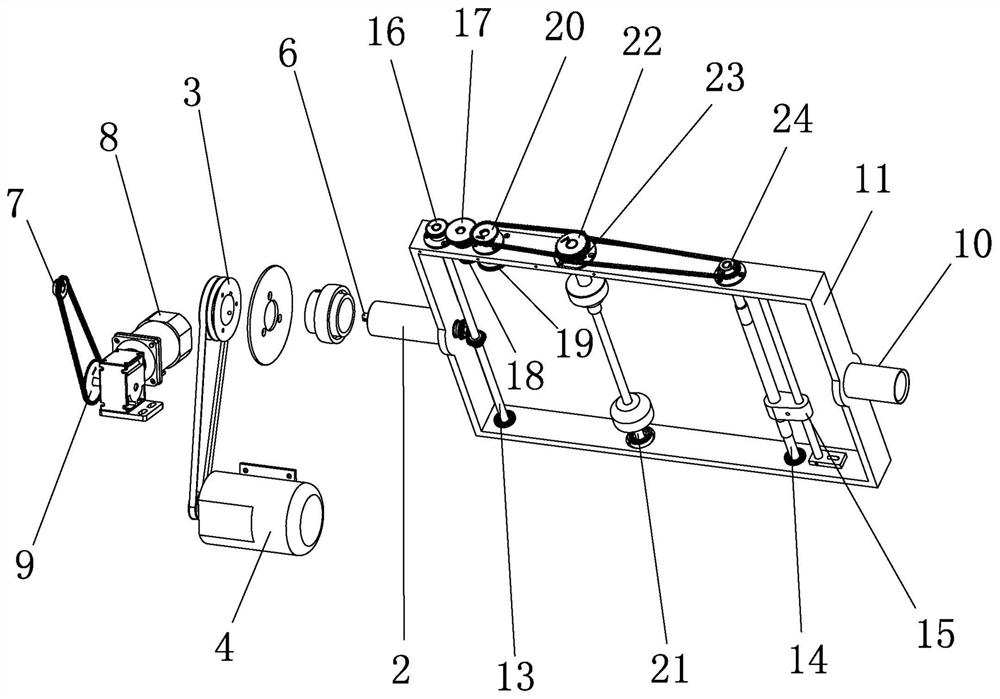

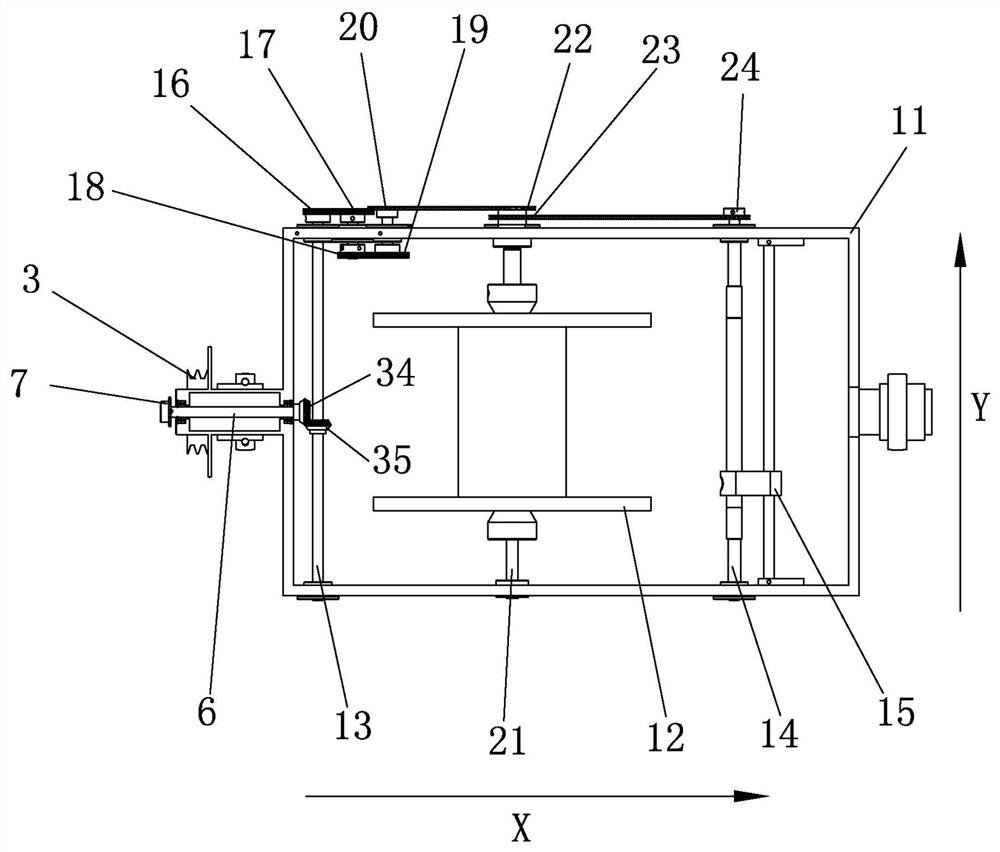

[0022] refer to Figure 1 to Figure 5 , an embedded stranding machine with a compact structure, which is characterized in that it includes a stranding wire take-up mechanism, and the stranding wire take-up mechanism includes a mounting frame 1, a stranding rotor 11 and a winding mechanism; The left and right sides are respectively installed on the mounting frame 1 through the X-direction first stranded wire shaft 2 and the second wire stranded wire shaft 10; 2 is a hollow shaft, and a speed regulating shaft 6 is coaxially installed in the first stranded wire shaft 2; the inner end of the first stranded wire shaft 2 is fixedly connected with the stranded wire rotor 11, and the outer end is connected with a power motor 4; The winding mechanism includes a Y-direction transmission shaft 13, a winding shaft 21 and a spool 14. The transmission shaft 13, the winding shaft 21 and the spool 14 are linked by a transmission mechanism. The transmission shaft 13, the winding shaft 21 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com