Automatic snow removal cable for cold and cold mountainous areas

A technology for cables and mountainous areas, which is applied in the field of automatic snow removal cables in alpine mountainous areas. It can solve the problems of inconvenient use, inconvenient control, inconvenient snow removal in sections, etc., and achieve the effect of avoiding sliding and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

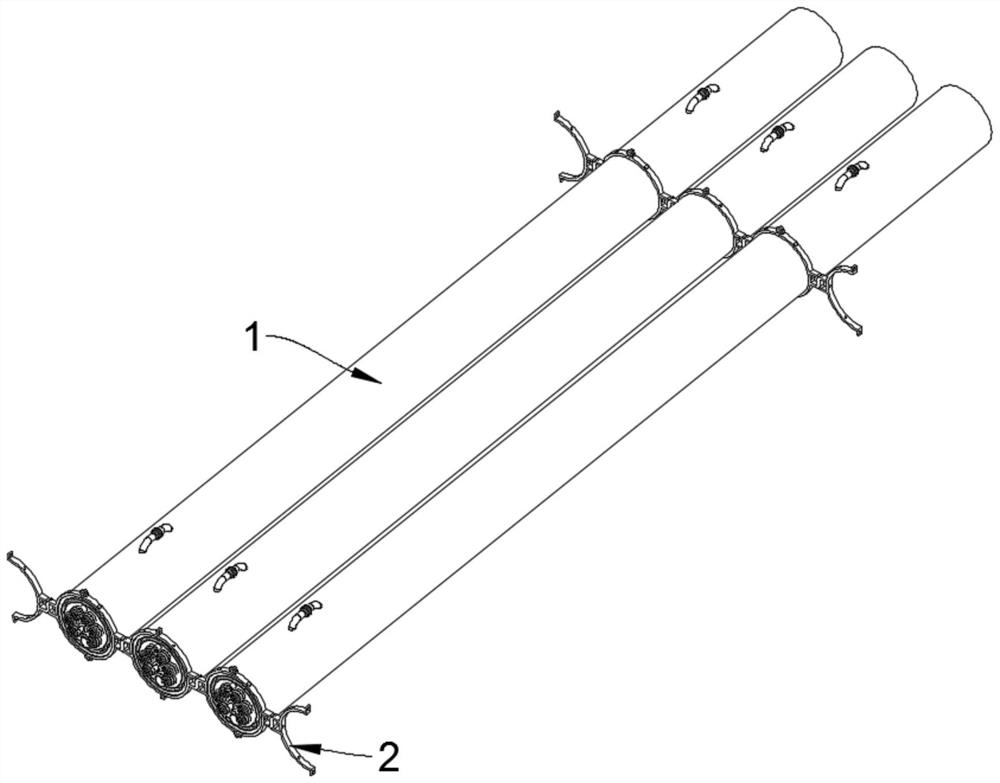

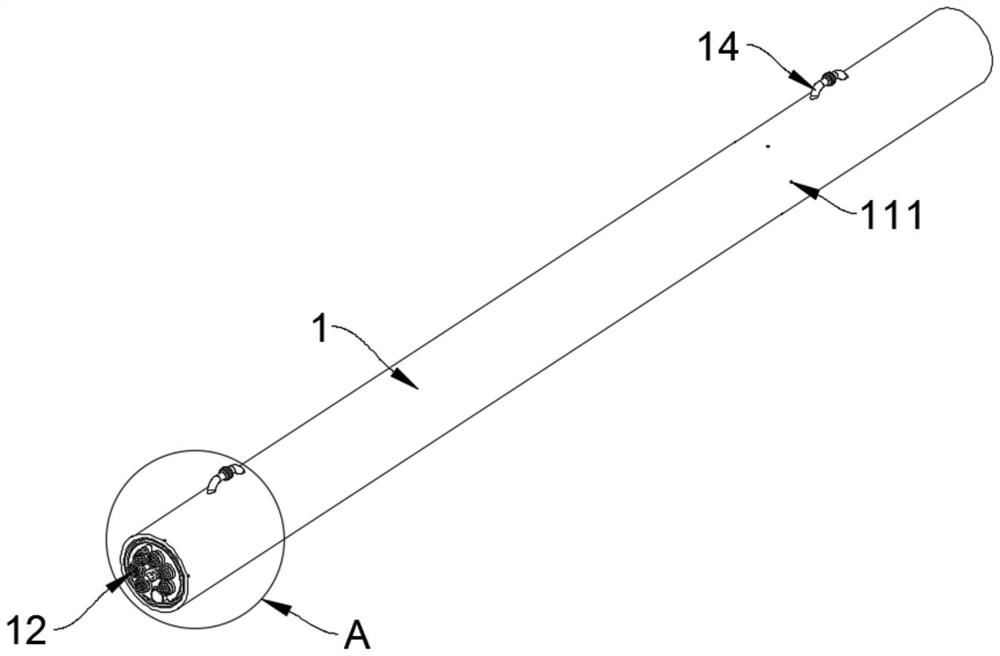

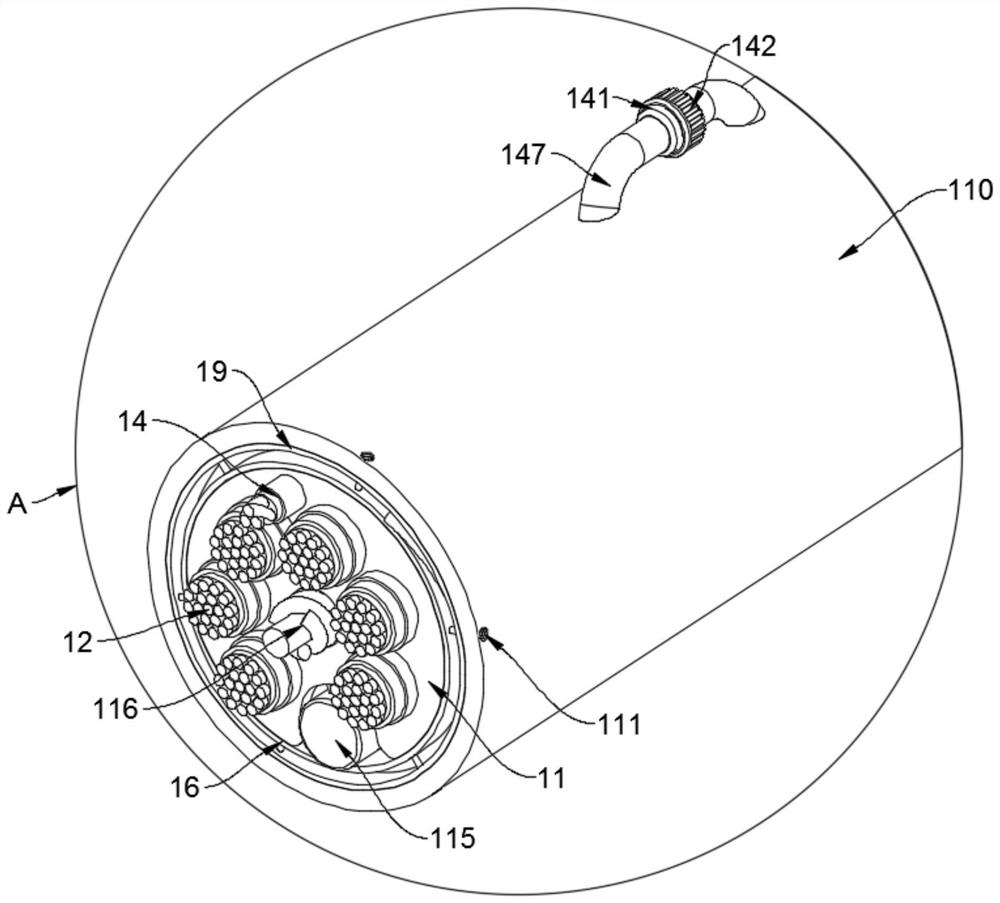

[0024] see Figure 1-9 As shown in the figure, an automatic snow removal cable for alpine mountains includes a cable 1 and a connector 2, and the cables 1 are assembled through the connector 2, so that a row is formed between the cables 1. The cable 1 includes an inner frame 11, and the inner frame The inner two sides of the inner frame 11 are evenly plugged with the main conductor 12, the inner frame 11 is a sheet-like structure, and the mica powder 13 is filled between the inner frame 11, the upper end of the inner frame 11 is inserted with the auxiliary conductor 14, the main conductor 12 and The auxiliary conductors 14 are all wrapped between the mica powders 13 , and the main conductors 12 and between the main conductors 12 and the auxiliary conductors 14 are isolated by the mica powders 13 , and the two sides of the inner skeleton 11 are evenly opened with first plugs The main conductor 12 is inserted into the first insertion hole 1111, the upper end of the inner frame 1...

Embodiment 2

[0027] see Figure 1-9 As shown in the figure, an automatic snow removal cable for alpine mountains includes a cable 1 and a connector 2, and the cables 1 are assembled through the connector 2, so that a row is formed between the cables 1. The cable 1 includes an inner frame 11, and the inner frame The inner two sides of the inner frame 11 are evenly plugged with the main conductor 12, the inner frame 11 is a sheet-like structure, and the mica powder 13 is filled between the inner frame 11, the upper end of the inner frame 11 is inserted with the auxiliary conductor 14, the main conductor 12 and The auxiliary conductors 14 are all wrapped between the mica powders 13 , and the main conductors 12 and between the main conductors 12 and the auxiliary conductors 14 are isolated by the mica powders 13 , and the two sides of the inner skeleton 11 are evenly opened with first plugs The main conductor 12 is inserted into the first insertion hole 1111, the upper end of the inner frame 1...

Embodiment 3

[0030] see Figure 1-9 As shown in the figure, an automatic snow removal cable for alpine mountains includes a cable 1 and a connector 2, and the cables 1 are assembled through the connector 2, so that a row is formed between the cables 1. The cable 1 includes an inner frame 11, and the inner frame The inner two sides of the inner frame 11 are evenly plugged with the main conductor 12, the inner frame 11 is a sheet-like structure, and the mica powder 13 is filled between the inner frame 11, the upper end of the inner frame 11 is inserted with the auxiliary conductor 14, the main conductor 12 and The auxiliary conductors 14 are all wrapped between the mica powders 13 , and the main conductors 12 and between the main conductors 12 and the auxiliary conductors 14 are isolated by the mica powders 13 , and the two sides of the inner skeleton 11 are evenly opened with first plugs The main conductor 12 is inserted into the first insertion hole 1111, the upper end of the inner frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com