Production process of photosensitive monomer material

A technology of photosensitive monomer and production process, applied in the direction of photosensitive materials for opto-mechanical equipment, etc., can solve the problems of inconvenience for large-scale mass production of enterprises and high price of polymer materials, achieve low production cost and improve molding processing performance. , the effect of good photosensitive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

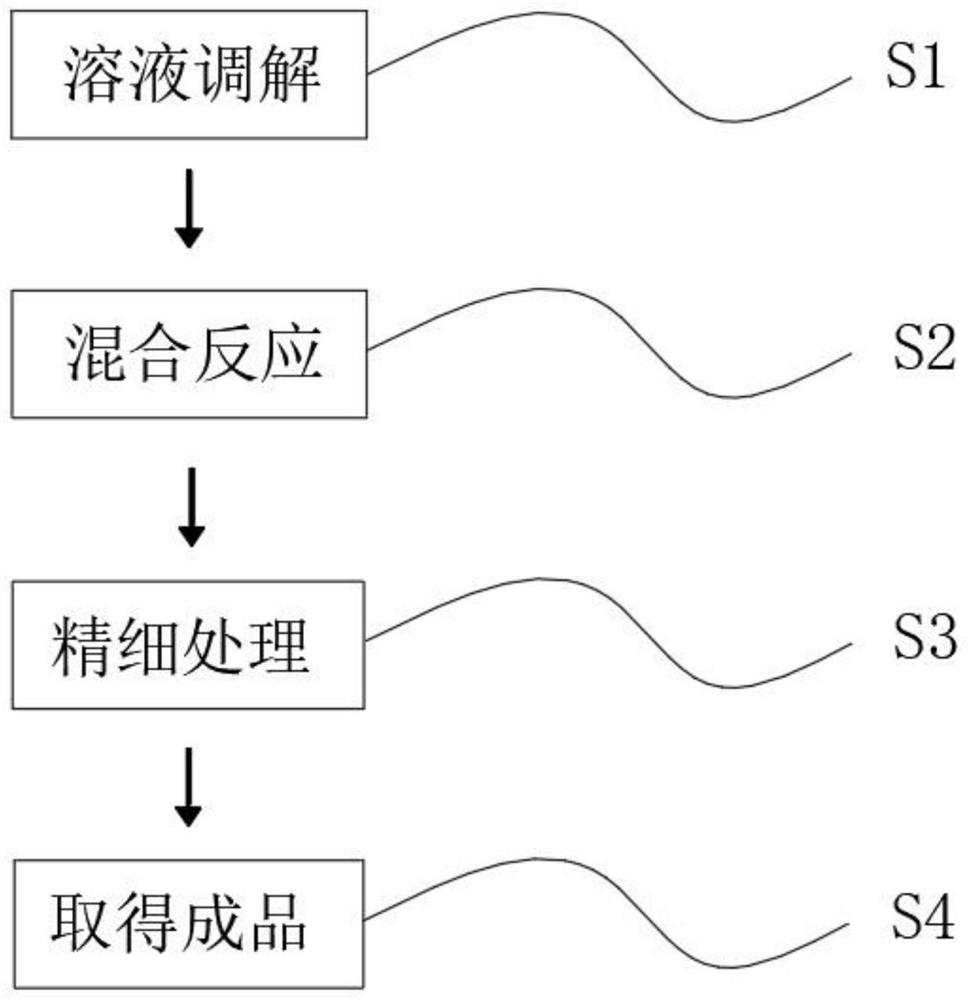

[0022] Example 1, please refer to figure 1 , the present invention provides a technical scheme: the production process of the photosensitive monomer material, comprising the following steps:

[0023] S1: Solution adjustment, first take deionized water and photosensitive resin, dilute to 155ml / l working solution when using, then measure pH with acidity meter, then adjust pH, then take acrylamide and diacetone acrylamide, after obtaining the acrylamide and diacetone acrylamide in conditioned deionized water:

[0024] S2: Mixing reaction, then weigh the initiator and add it into the reaction kettle, and gradually increase the temperature of the reaction kettle itself, and keep it for 4 hours. After the maintenance, the initiator is added to the reaction kettle again, and the polymerization operation is carried out for 10 hours to obtain the photosensitive polymer:

[0025] S3: Fine treatment, then add defoaming agent to the reaction kettle, and continuously defoaming the solutio...

Embodiment 2

[0035] Example 2, please refer to figure 1 , the present invention provides a technical scheme: the production process of the photosensitive monomer material, comprising the following steps:

[0036] S1: Solution adjustment, first take deionized water and photosensitive resin, dilute to 120ml / l working solution when using, then measure pH with acidity meter, then adjust pH, then take acrylamide and diacetone acrylamide, after obtaining acrylamide and diacetone acrylamide in conditioned deionized water:

[0037] S2: Mixing reaction, then weigh the initiator and add it to the reaction kettle, and gradually increase the temperature of the reaction kettle itself, and keep it for 3 hours. After the maintenance, the initiator is added to the reaction kettle again, and the polymerization operation is carried out for 8 hours to obtain the photosensitive polymer:

[0038] S3: Fine treatment, then add defoaming agent to the reaction kettle, and continuously defoaming the solution in th...

Embodiment 3

[0048] Example three, please refer to figure 1 , the present invention provides a technical scheme: the production process of the photosensitive monomer material, comprising the following steps:

[0049] S1: Solution adjustment, first take deionized water and photosensitive resin, dilute to 200ml / l working solution when using, then measure pH with acidity meter, then adjust pH, then take acrylamide and diacetone acrylamide, after obtaining the acrylamide and diacetone acrylamide in conditioned deionized water:

[0050] S2: Mixing reaction, then weigh the initiator and add it to the reaction kettle, and gradually increase the temperature of the reaction kettle itself, and keep it for 4 hours. After holding, the initiator is added to the reaction kettle again, and the polymerization operation is carried out for 8 hours to obtain the photosensitive polymer:

[0051] S3: Fine treatment, then add defoaming agent to the reaction kettle, and continuously defoaming the solution in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com