Blowout prevention device and method for oil well

A technology for blowout prevention devices and oil wells, which is applied in wellbore/well valve devices, earthwork drilling, wellbore/well components, etc. It can solve problems such as high safety risks, difficult operation, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

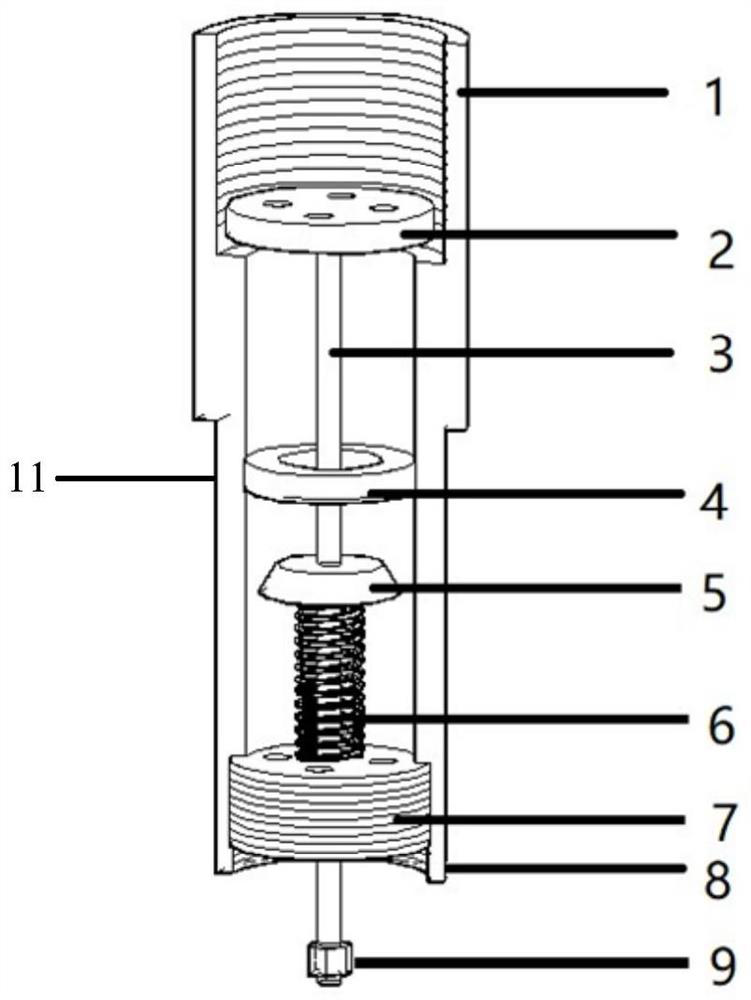

[0033] In order to make the objectives, technical solutions and advantages of the present application clearer, the embodiments of the present application will be further described in detail below with reference to the accompanying drawings.

[0034] It should be noted that, in the process of describing the oil well blowout prevention device and method provided by the embodiments of the present application, the words "top", "bottom", "upper" and "lower" are figure 1 For reference, when the oil well blowout preventer or method provided by the embodiments of the present application is used in different scenarios, the meanings of "top", "bottom", "upper" and "lower" will also change accordingly.

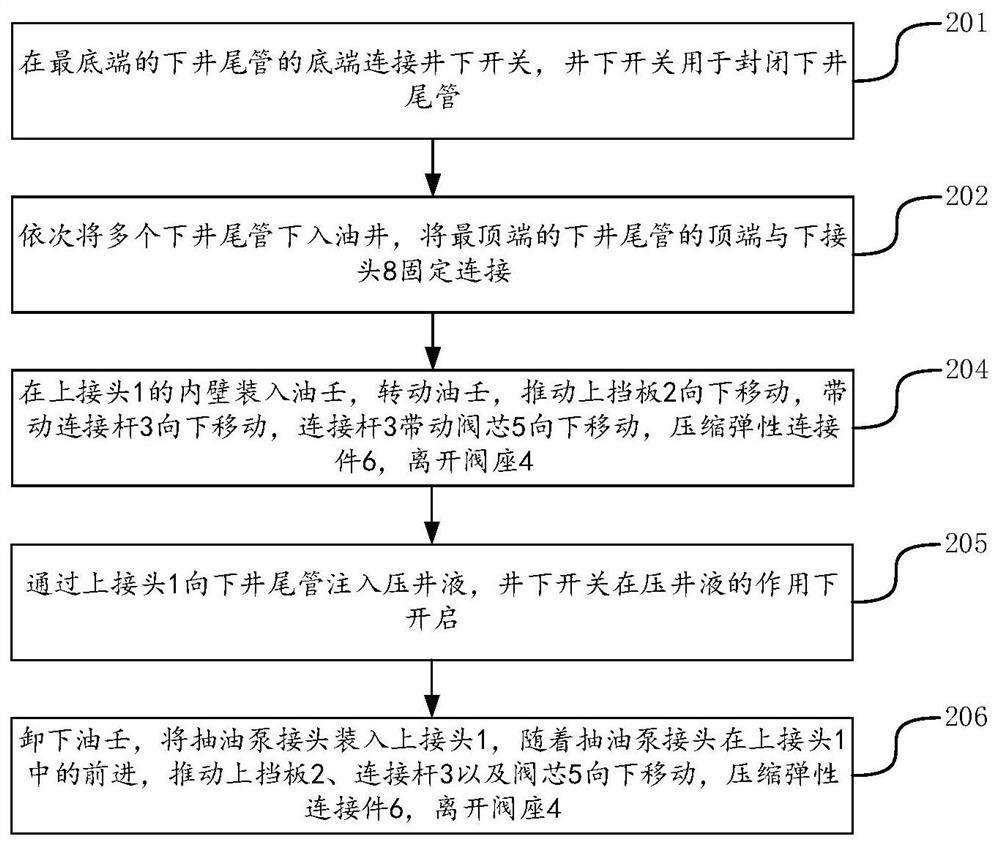

[0035] The present application provides a method for running a liner under pressure in an oil well, due to the effect of the pressure in the well, the well fluid is uncontrollably sprayed out along the inner cavity of the oil pipe, causing environmental pollution, bringing about great hid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com