Blowout control tubing head and oil and gas wellhead device

A wellhead device and tubing head technology, which is applied in wellbore/well parts, earthwork drilling, sealing/packing, etc., and can solve the problems that the tubing head cannot prevent blowout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

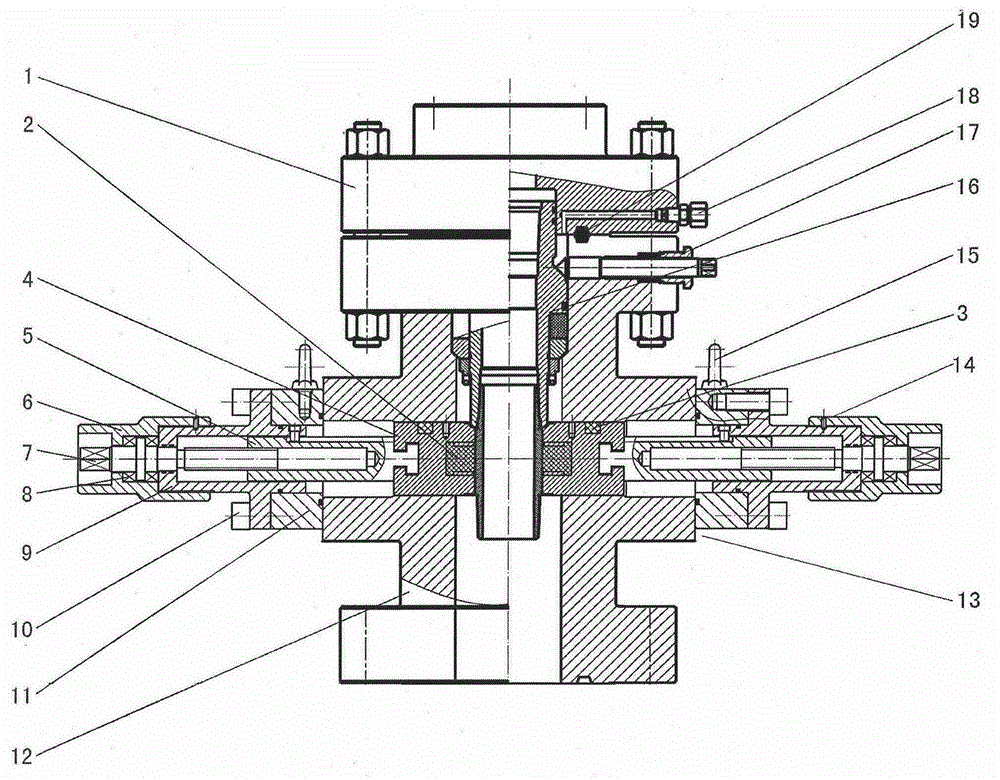

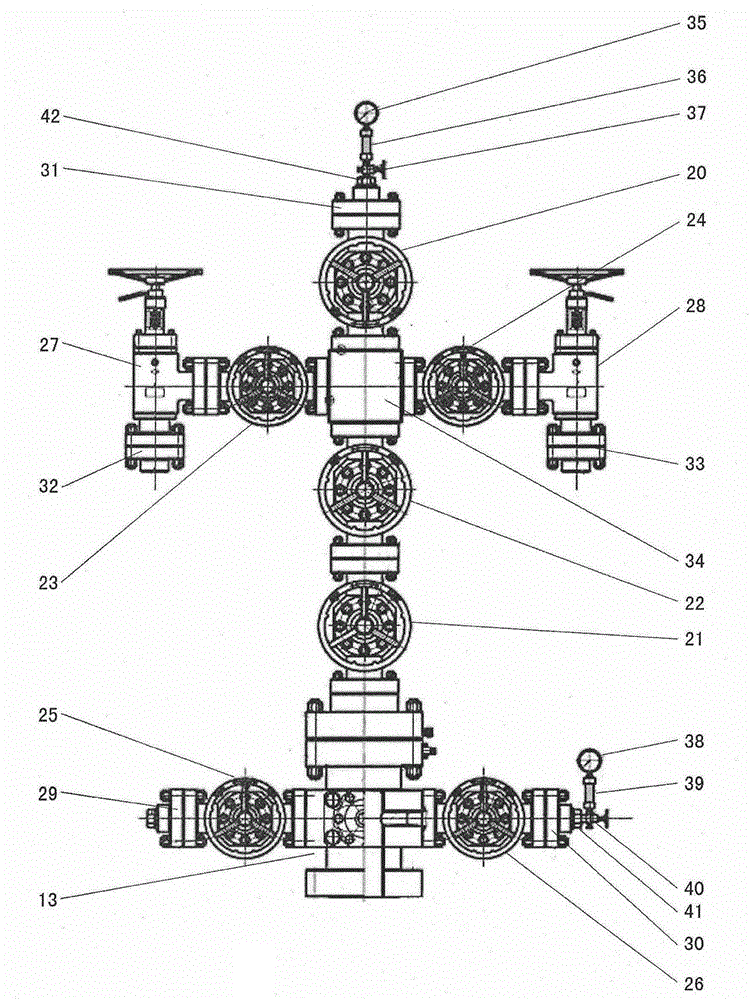

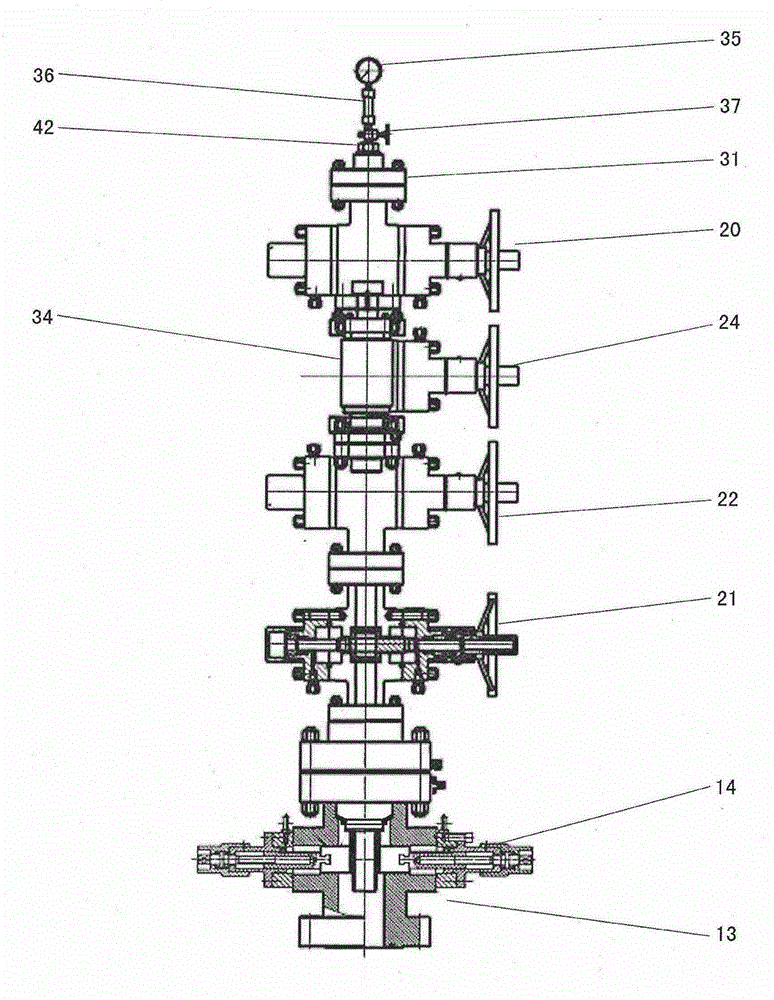

[0010] refer to figure 1 , figure 2 , image 3 Make the invention.

[0011]A blowout-proof oil pipe head and an oil-gas wellhead device thereof, which include a blowout-proof oil pipe head and an oil-gas wellhead equipped with a blowout-proof oil pipe head, and a manual blowout prevention mechanism is arranged on the blowout-proof oil pipe head. The blowout-proof tubing head is mainly composed of a tubing hanger 16, a housing 12, and a manual ram blowout-preventing assembly 14. The blowout-proof oil pipe head includes two manual ram blowout preventer assemblies, and the two manual ram blowout preventer assemblies cooperate with each other to form a structure of a pair of manual ram blowout preventer assemblies. The manual blowout prevention mechanism is an integral manual blowout prevention structure formed by the mutual cooperation and connection of the housing and a pair of manual ram blowout prevention assemblies. The blowout-proof tubing head also includes an upper fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com