A compound metal material sealing inner blowout prevention tool

A technology of composite metal materials and internal blowout prevention, which is applied in sealing/packing, wellbore/well parts, earthwork drilling and production, etc., to achieve the effect of fast processing, simple and reasonable structure, and precise clinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

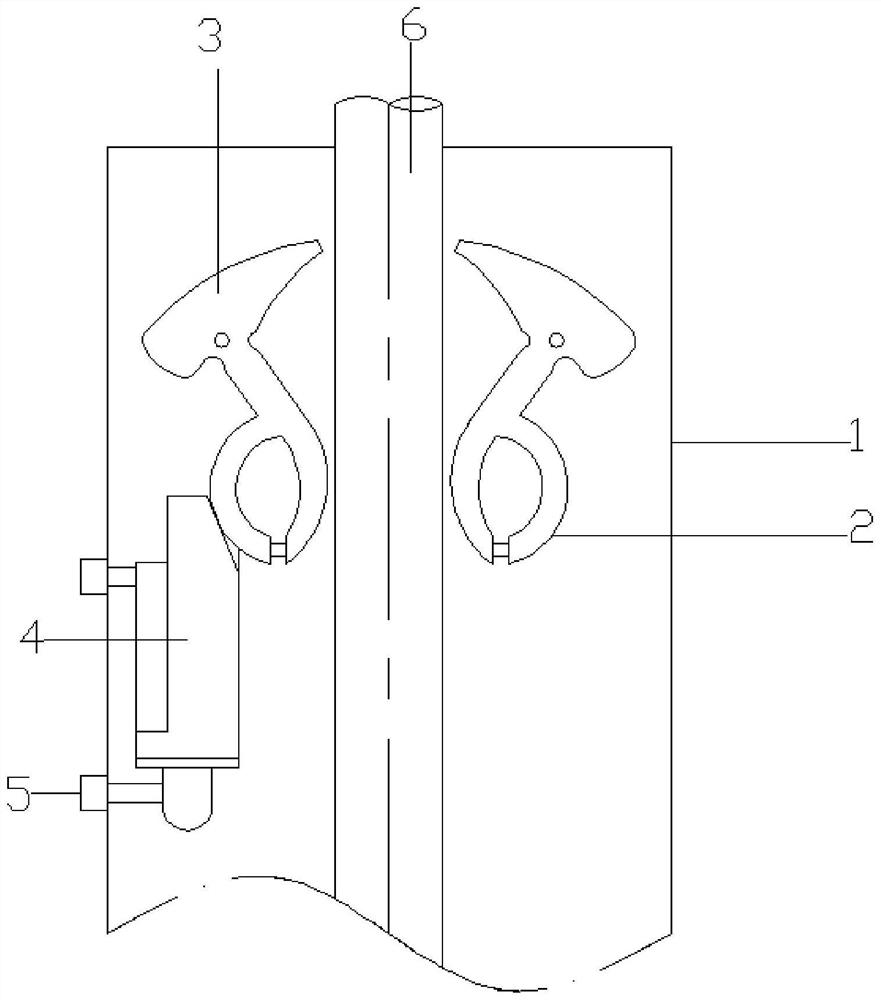

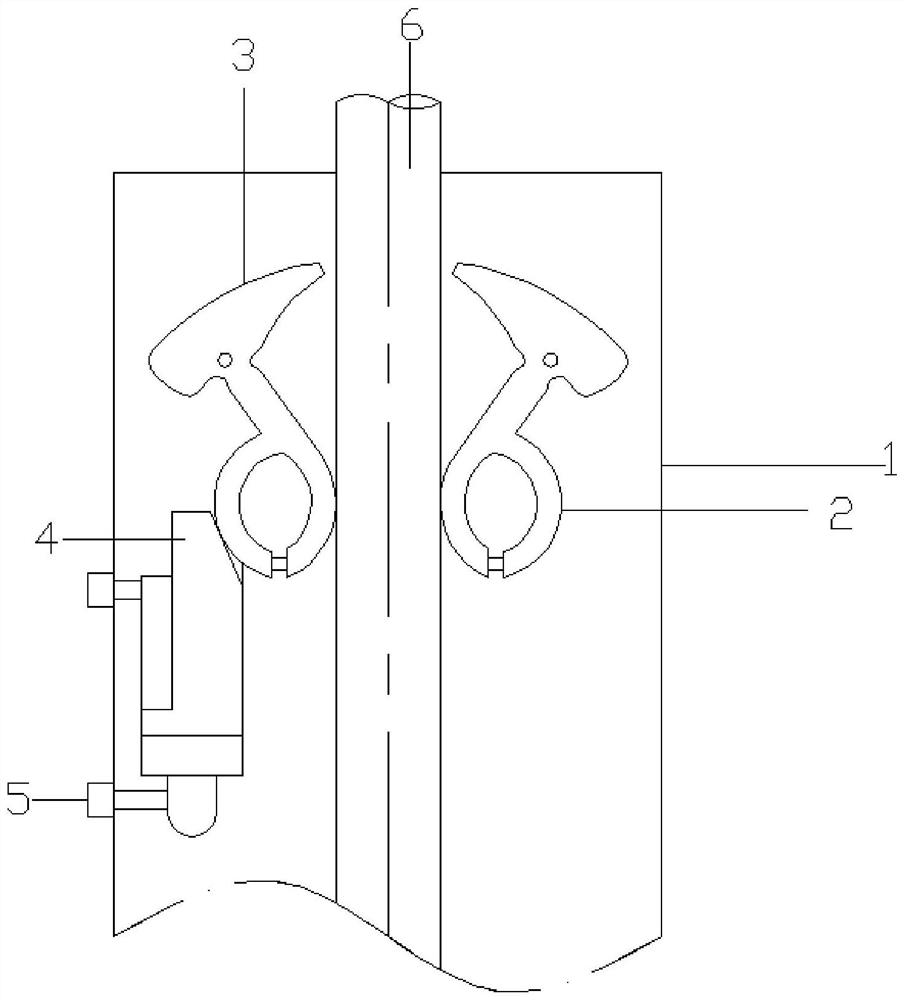

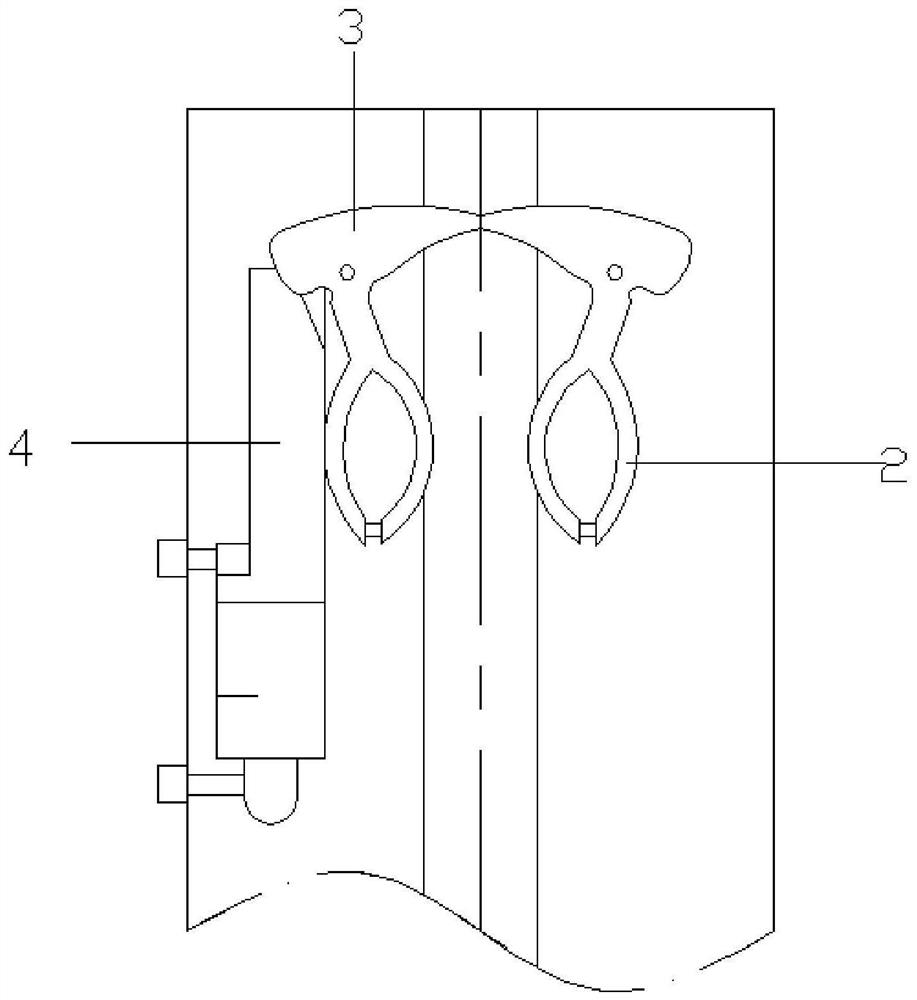

[0056] In practical applications, the user pushes the slider 4 to move upward through the hydraulic oil inlet and outlet port 5 and squeezes the second deformation part 22, wherein the elastic deformation part 222 in the second deformation part 22 is deformed, and the elastic deformation part 222 is deformed through transmission. The force convex head 223 squeezes the extruded sealing part 221, and the extruded sealing part 221 deforms to the side of the drill string 6, squeezes and hugs the drill string 6 to seal and realize blowout prevention, as attached image 3 As shown; the slider 4 continues to push upwards under the action of the oil inlet and outlet of the hydraulic oil inlet and outlet 5, wherein the first deformation part 21 is deformed, the sealing guide bowl 31 of the second sealing blowout prevention part 3 guides and moves, and the slider 4 moves and pushes The sealing guide bowl 31 moves and hugs tightly to realize blowout prevention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com