Airflow preventing device used for oil-gas pipeline welding

A technology for oil and gas pipelines and inflatable devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as outflow, and achieve the effect of no need to stop production for maintenance, realize pressure operation, and realize remote control or wireless control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

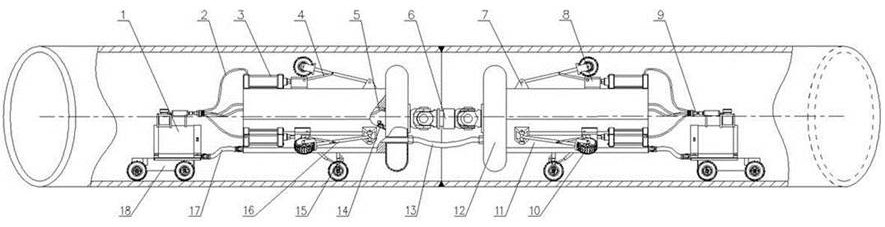

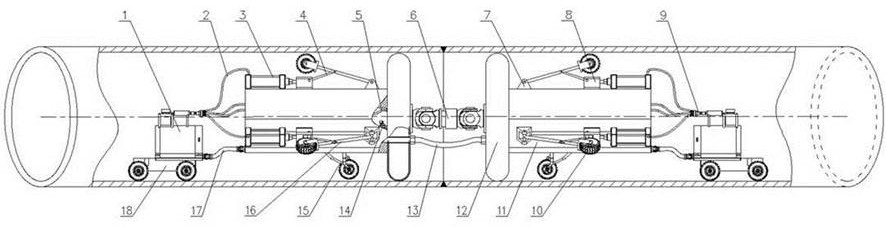

[0013] Such as figure 1 and figure 2 , an anti-airflow device for oil and gas pipeline welding, mainly composed of an inflator 1, a cylinder inflation line 2, a cylinder 3, a sliding support shaft 4, an airbag inflation line 5, a universal joint 6, a fixed hinge seat 7, and a sliding hinge seat 8. Composed of multi-way joint 9, centering wheel 10, box body 11, air bag 12, ventilation hose 13, air bag release valve 14, load-bearing wheels 15, fixed support shaft 16, traction hinge 17 and tractor 18, it is characterized in that : the structure of the anti-airflow device is symmetrical about the universal joint 6; the inflation device 1 is installed on the tractor 18, and the cylinder 3 is inflated through the cylinder inflation pipeline 2, and the airbag 12 is inflated through the airbag inflation pipeline 5; the said Cylinder 3, sliding support shaft 4, fixed hinge seat 7, sliding hinge seat 8, centering wheel 10 and fixed support shaft 16 are all installed on the casing 11; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com