Industrial robot remote monitoring and data processing system

A data processing system and industrial robot technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of image data processing errors, inability to apply precise robots, and insufficient use of a large amount of historical data to reduce huge losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solutions and beneficial effects of the present invention clearer, preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

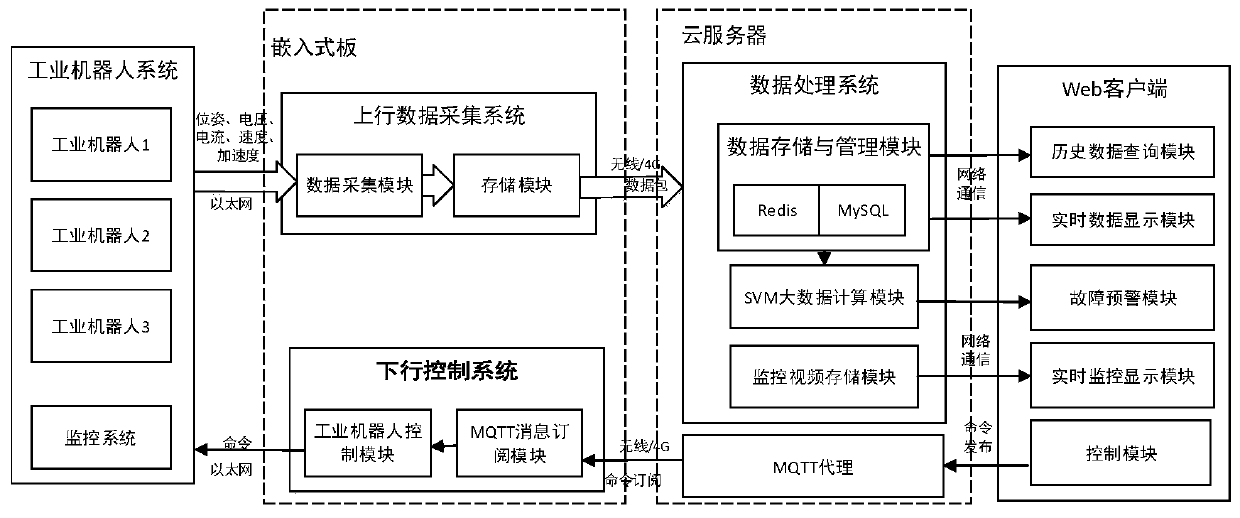

[0028] An industrial robot remote monitoring and data processing system, as attached figure 1As shown, it is composed of industrial robot system, uplink data acquisition system, downlink control system, data processing system, Web client and MQTT agent. The industrial robot system is composed of UR5 industrial robot, ABB IRB120 industrial robot and Haikang monitoring camera. Uplink The data acquisition system and downlink control system are located in the TI Cortex-A8AM335X embedded board, the onboard Linux-arm system, the data processing system and the MQTT agent are located in the cloud server, and the industrial robot system is connected to the embedded board through industrial Ethernet to realize data interaction. The embedded board is remote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com