Method and system for preparing red mud-biochar composite catalyst and purifying tar

A composite catalyst and biocoke technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of sintering of metal active sites, poor catalyst stability, catalytic Low efficiency and other problems, to achieve the effect of slowing down sintering and agglomeration, improving quality and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

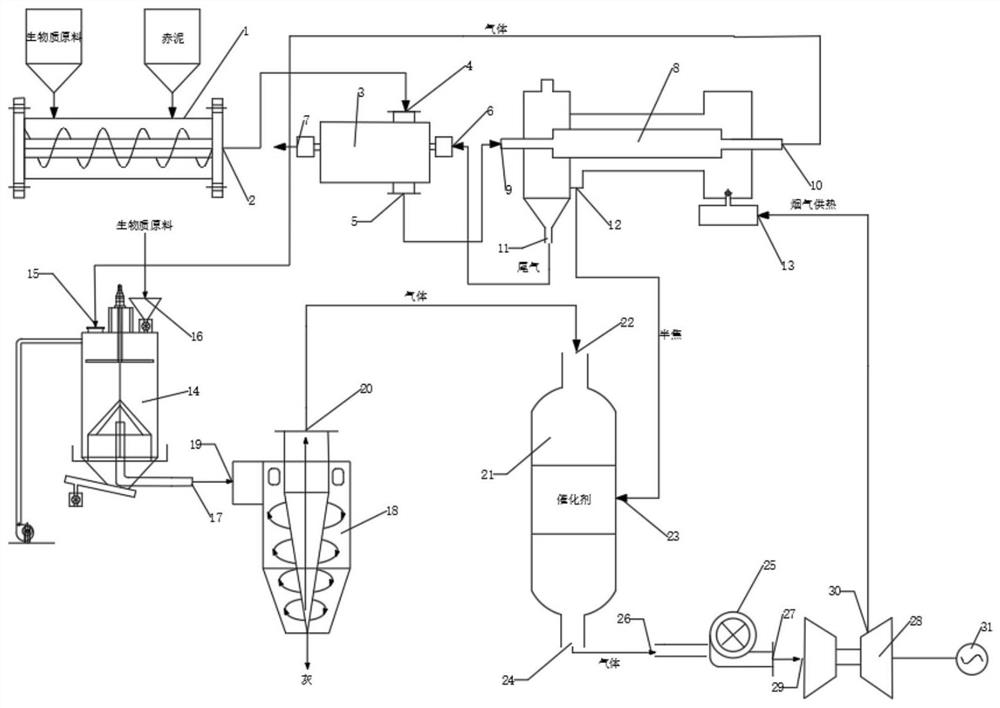

[0031] A system for preparing a red mud-biocoke composite catalyst and tar purification includes: a mixer 1, a drum dryer 3, a rotary furnace 8, a downdraft gasifier 14, a cyclone dust collector 18, and a fixed bed reformer 21. Induced draft fan 25, gas turbine 28, generator 31;

[0032] The outlet 2 of the mixer 1 is connected to the material inlet 4 of the drum dryer 3, the material outlet 5 of the drum dryer 3 is connected to the material inlet 9 of the rotary furnace 8, and the pyrolysis volatile matter outlet 10 of the rotary furnace 8 is connected to the downdraft gas The gas inlet 15 of the gasifier 14 is connected, the gas outlet 17 of the downdraft gasifier 14 is connected to the gas inlet 19 of the cyclone 18, the gas outlet 20 of the cyclone 18 is connected to the gas inlet 22 of the fixed bed reformer 21, The gas outlet 24 of the fixed bed reformer 21 is connected to the inlet 26 of the induced draft fan 25, the gas outlet 27 of the induced draft fan 25 is connecte...

Embodiment

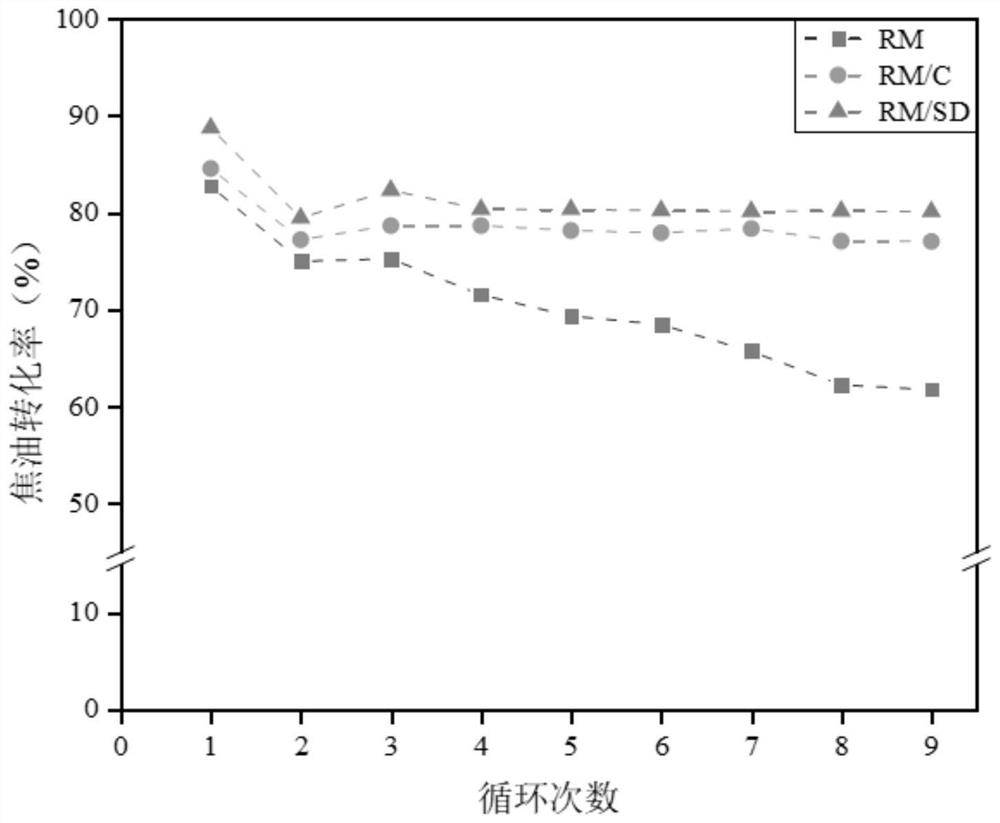

[0035] Red mud and wood chips were mixed and stirred at a ratio of 1:1, dried at 105 °C for 24 h, and then subjected to carbothermic reduction (in situ pyrolysis) under an inert nitrogen atmosphere for 1 h to obtain a red mud-biocoke composite The catalyst, in order to embody the innovative point of the present invention, also adopts wood chips pyrolysis coke and red mud to be mixed and then pyrolyzed, and the prepared catalyst is a red mud-biocoke catalyst; Mainly present Fe 0 In addition, the surface area of the red mud-biocoke composite catalyst obtained by the method of the present invention reaches 99.56 m 2 / g, while the specific surface area of the red mud / biocoke catalyst obtained after pyrolysis coke and red mud is directly mixed and pyrolyzed is 53.16m 2 / g, indicating that the catalyst obtained in the present invention significantly improves the pore structure of the catalyst. In addition, the purification and removal effects of red mud (RM), red mud / biocoke (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com