Water-based drilling fluid composition and water-based drilling fluid

A technology for water-based drilling fluid and composition, applied in the field of water-based drilling fluid composition and water-based drilling fluid, can solve problems such as wellbore instability, achieve the effects of increasing drilling speed, excellent performance, and promoting wellbore stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

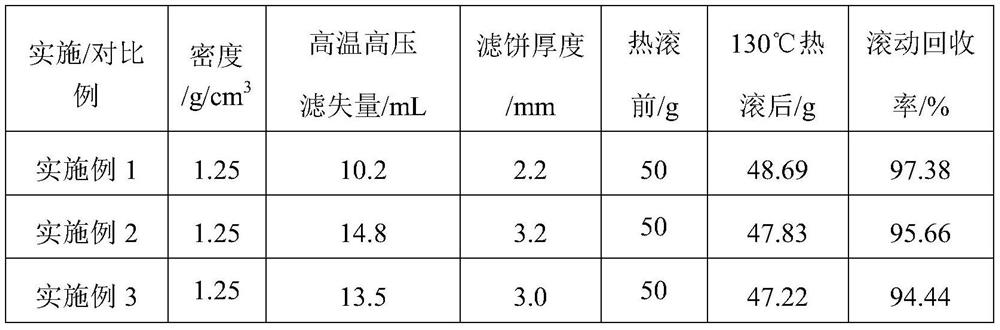

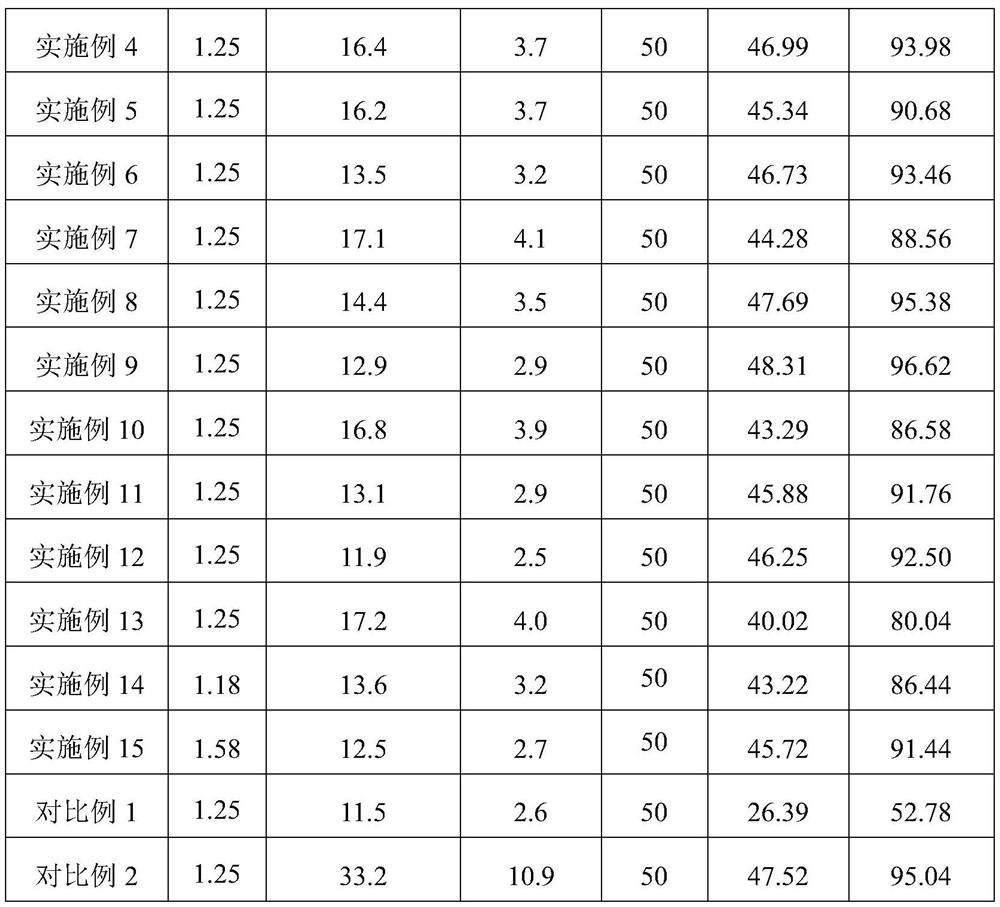

Examples

preparation example Construction

[0025] The preparation of the above-mentioned nano-silica blocking agent can refer to the technology of silane coupling agent and polymerized monomer in the prior art to modify the surface of inorganic nanoparticles, in order to reduce the cost of nano-silica blocking agent, and Make the obtained nano-silica plugging agent more suitable for the water-based drilling fluid of the present application, preferably adopt the following preparation method to obtain the nano-silica plugging agent:

[0026] (1) put 4-10 parts by weight of nano-silicon dioxide powder in a 100°C vacuum drying oven to dry to constant weight, and dry the dried nano-silicon dioxide powder and 3-6 parts by weight of silane coupling agent It is sequentially added to 80-120 parts by weight of absolute ethanol, and the mixture is dispersed in a supersonic emulsification disperser for 1-1.5 hours.

[0027] (2) Transfer the mixed solution prepared in step (1) into a three-necked flask, continue to flow nitrogen at...

Embodiment 1

[0046] Preparation of nano-silica plugging agent:

[0047] (1) put 4 parts by weight of nano-silicon dioxide powder (20nm) in a 100°C vacuum drying oven and dry to constant weight, and dry the nano-silica powder after drying and 10 parts by weight of vinyl tri(β) -Methoxyethoxy)silane was sequentially added to 80 parts by weight of absolute ethanol, and the mixture was dispersed in a ultrasonic emulsification disperser for 1.5h.

[0048] (2) The mixed solution prepared in step (1) was transferred into a three-necked flask, and nitrogen was continuously passed through at 70° C. for 10 hours, and the reaction product was purified and dried with acetone.

[0049] (3) in 100 parts by weight of deionized water, successively add the isopropanol of 1 weight part, the methyl methacrylate of 2 weight parts, the obtained emulsifier solution is stirred for 8 minutes at light speed, and the emulsion is transferred to four in the flask.

[0050] (4) The reaction product dried in step (2)...

Embodiment 2

[0060] The difference between Example 2 and Example 1 is that the particle size of the nano-silica powder is 10 nm, and a water-based drilling fluid is finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com