Bimetal oxide modified boron fuel and preparation method thereof

A bimetallic oxide, fuel technology, applied in offensive equipment, climate sustainability, explosives processing equipment, etc., can solve the problem of further improvement of ignition and combustion performance, to improve ignition and combustion performance, improve ignition performance, Effect of low initial oxidation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

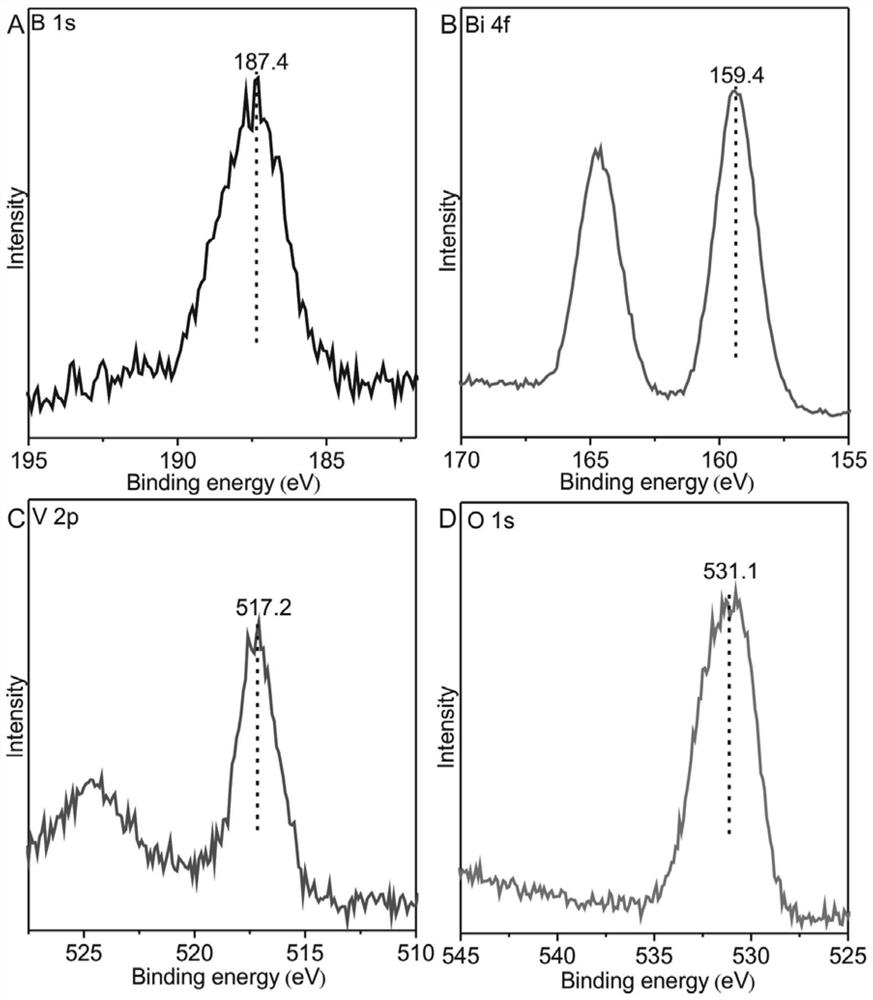

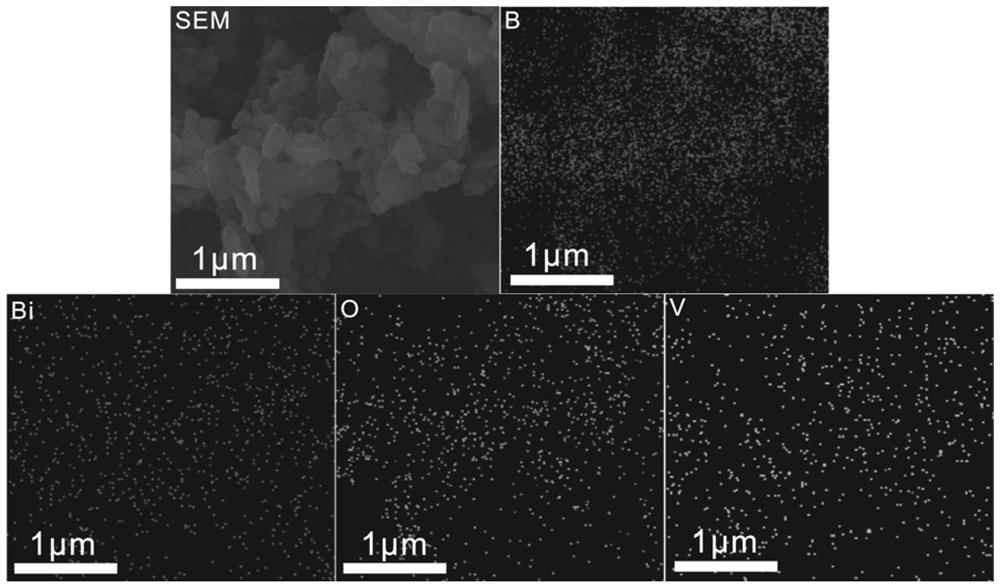

[0067] The present embodiment provides a method for preparing a bimetallic oxide modified boron fuel, which adopts an impregnation-precipitation deposition method to perform bimetallic oxide modification on the surface of boron powder to form a bimetallic oxide modified boron fuel;

[0068] The bimetallic oxide is a composite binary bimetallic oxide of bismuth oxide and vanadium oxide;

[0069] The impregnation-precipitation deposition method is as follows: first, the solution of pentavalent vanadium salt is used as the impregnation solution, and the boron powder particles are completely infiltrated, and then dried and calcined to obtain the boron fuel loaded with vanadium oxide; 3 It is a bismuth source, and NaOH is used as a precipitant to precipitate on the surface of the vanadium oxide-loaded boron fuel to obtain a precipitated intermediate product, and the precipitated intermediate product is calcined and deposited to finally obtain a vanadium oxide-loaded boron fuel for d...

Embodiment 2

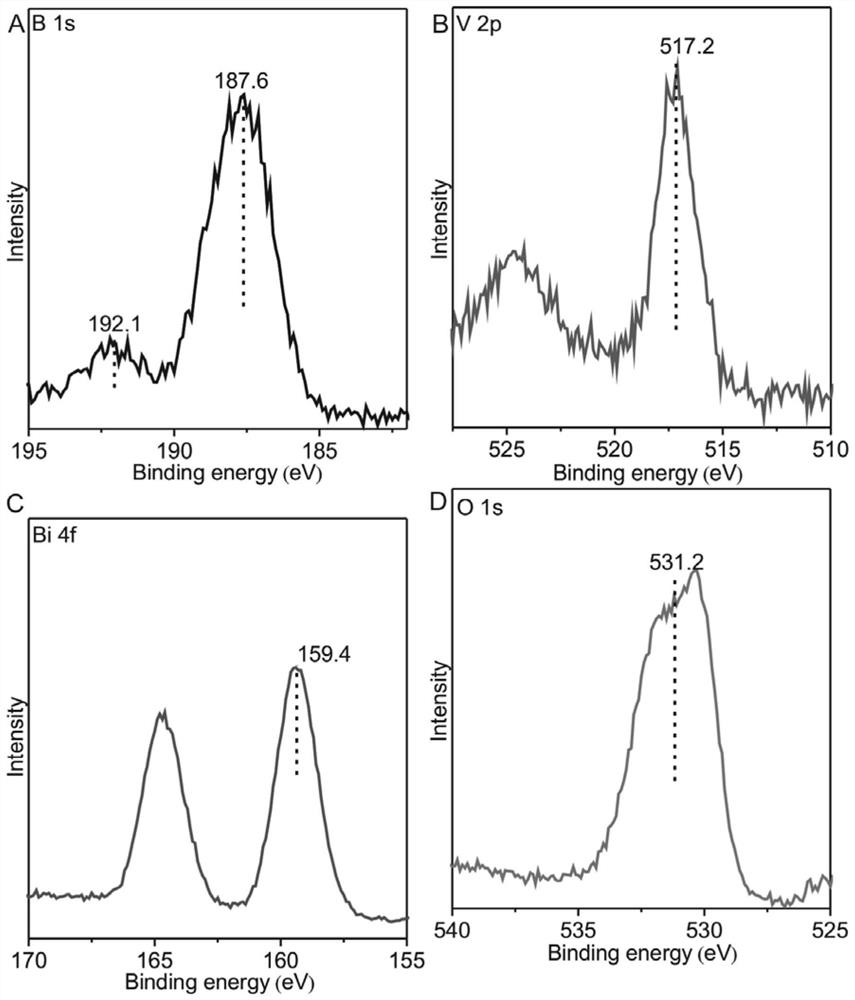

[0084] This embodiment provides a method for preparing a double metal oxide modified boron fuel, which adopts a precipitation deposition-impregnation method to modify the surface of the boron powder with double metal oxide to form a double metal oxide modified boron fuel;

[0085] The bimetallic oxide is a composite binary bimetallic oxide of bismuth oxide and vanadium oxide;

[0086] The precipitation deposition-impregnation method is: firstly with BiCl 3 It is a bismuth source, and NaOH is used as a precipitant to precipitate on the surface of the boron powder to obtain a precipitation intermediate product, and the precipitation intermediate product is calcined and deposited to obtain a boron fuel for depositing bismuth oxide; The bismuth oxide-deposited boron fuel particles are completely infiltrated, dried and calcined, and finally the vanadium oxide-loaded bismuth oxide-deposited boron fuel is obtained, that is, the bimetallic oxide modified boron fuel is prepared.

[00...

Embodiment 3

[0105] In this example, the combustion performance test of bimetallic oxide modified boron fuel is given. The test method of combustion performance is as follows: take an appropriate amount of bimetallic oxide modified boron fuel sample in the sample stage of the TG-DSC instrument, set the heating rate It is 10℃ / min, and the test temperature range is 50-1000℃. The exothermic peak temperature of the double metal oxide modified boron fuel prepared by the invention is advanced to 525-498° C., which is 150-200° C. earlier than that of pure boron powder.

[0106] Specifically, an appropriate amount of bimetallic oxide-modified boron fuel sample was taken in the sample stage of the TG-DSC instrument, and the combustion of the boron powder-supported bismuth oxide composite was carried out by thermogravimetry and differential calorimetry (TG-DSC). The performance was tested, the heating rate was 10°C / min, and the test temperature range was 50-1000°C. The exothermic peak temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com