Steel bar cutting equipment and control method thereof

A technology for cutting equipment and steel bars, which is applied in the field of steel bar cutting equipment and its control. It can solve problems such as damage to steel bar cutting equipment, splashing of cement blocks, and easy adhesion of cement to steel bars, so as to improve expression ability and clustering performance. , the effect of improving the accuracy of judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

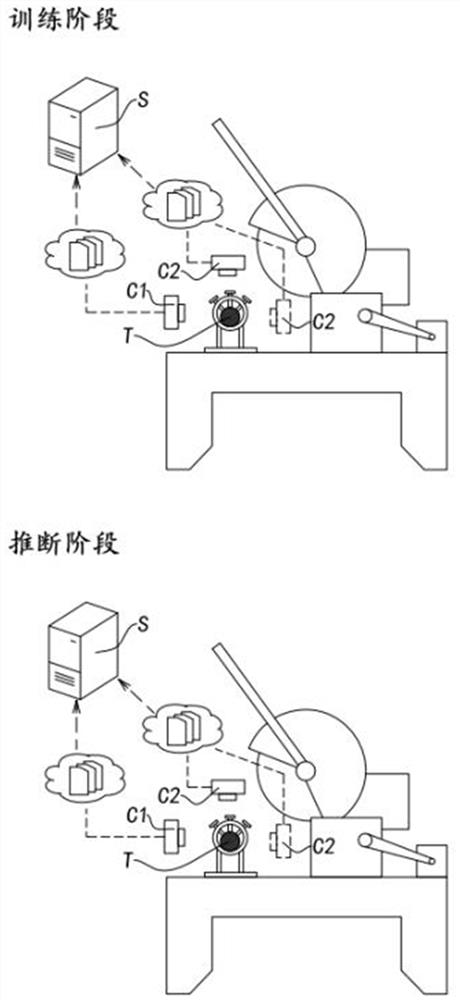

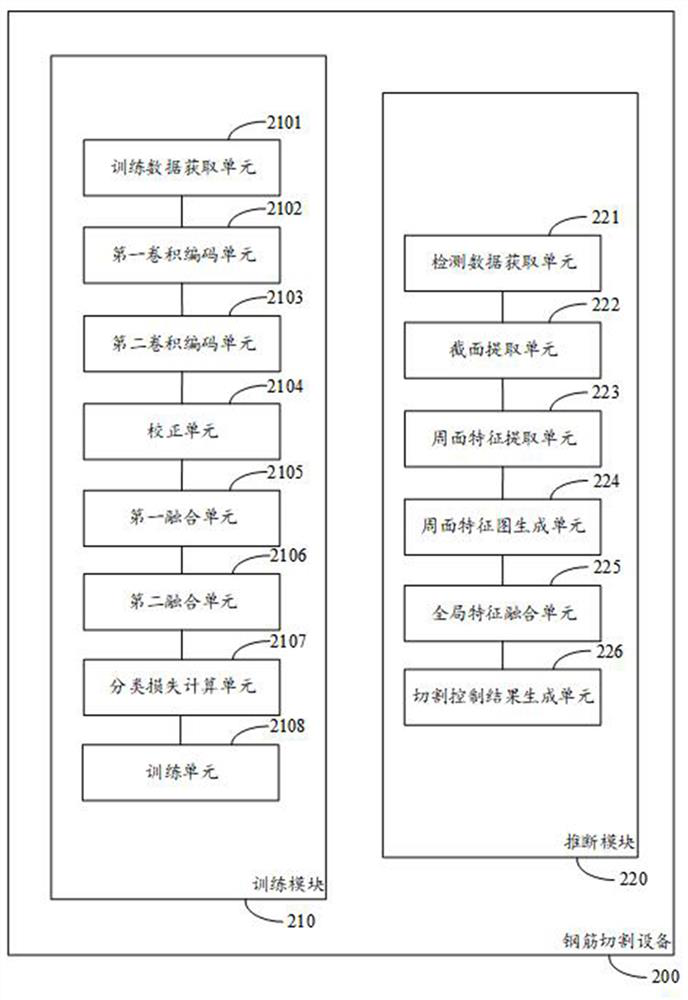

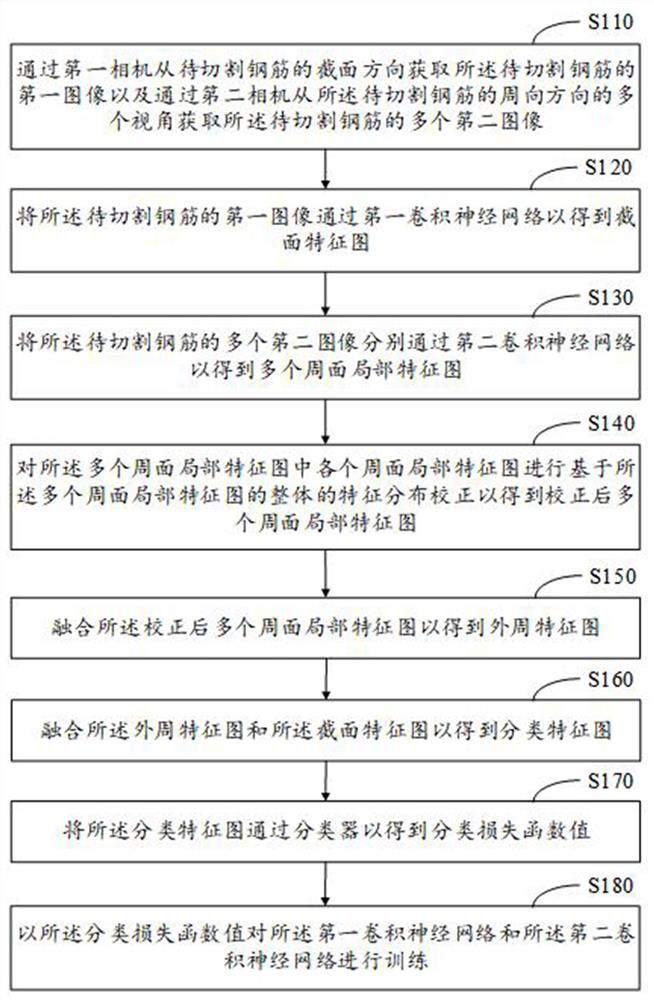

[0015] Hereinafter, exemplary embodiments according to the present application will be described in detail with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present application, rather than all the embodiments of the present application, and it should be understood that the present application is not limited by the example embodiments described herein.

[0016] Scenario overview

[0017] As mentioned above, when building houses and building foundations, steel bars are used to build shelves. The steel bars serve as a temporary support and are not consumables and can be reused. However, during construction, cement and other objects are easily attached to the steel bars. When cutting steel bars with cement attached with steel bar cutting equipment, if the cement on the surface of the steel bars is not cleaned, it will cause damage to the steel bar cutting equipment, and the cut cement blocks will splash an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com