Device for producing chloroquine phosphate and preparation process

A technology of chloroquine phosphate and a production device, which is applied in the directions of resisting vector-borne diseases, separation methods, filtration and separation, etc., can solve problems such as difficulty in concentrating pot and drying, affecting crystal quality, etc., to improve efficiency, improve preparation quality, reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

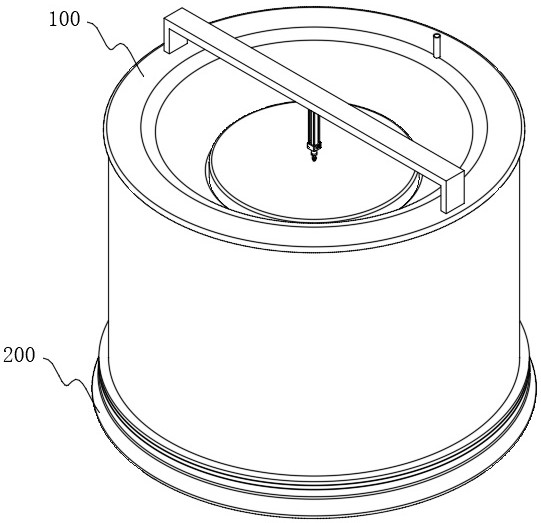

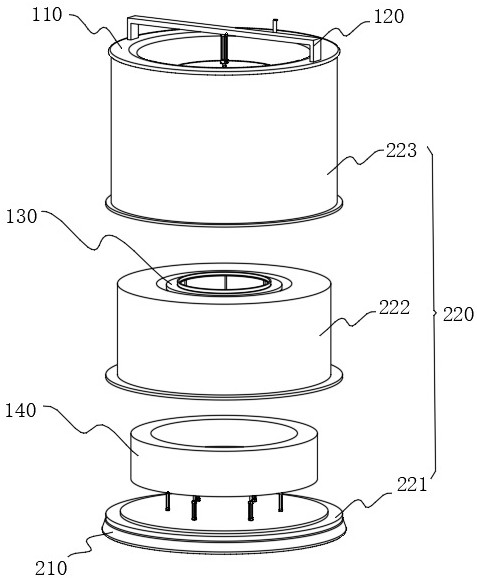

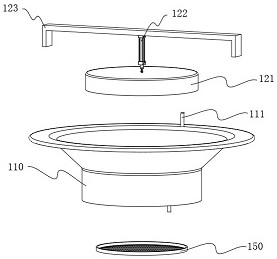

[0053] see Figure 1-Figure 3 As shown, the press-down assembly 120 includes a pressure plate 121, a first hydraulic rod 122 is arranged on the top of the pressure plate 121, a bracket 123 is arranged at the top of the first hydraulic rod 122, and the first hydraulic rod 122 is fixedly connected to the decolorizing pot 110 through the bracket 123. In addition, A filter element 150 is arranged between the decolorization pot 110 and the concentration pot 130 . In this embodiment, the filter element 150 is a filter screen, and the piston rod of the first hydraulic rod 122 is fixedly connected to the pressure plate 121 .

[0054] During preparation, first the first hydraulic rod 122 works to push the pressure plate 121 down through the piston rod until the top surface of the pressure plate 121 is lower than the top edge of the part where the decolorization pot 110 and the pressure plate 121 are attached. An injection cavity is formed between the top of the plate 121, purified wate...

Embodiment 2

[0057] Considering that the top of the platen 121 is in a horizontal state, the mixed solution attached to the outer wall of the platen 121 is not easy to flow down under the action of gravity, which often causes part of the mixed solution to adhere to its outer wall, thus causing waste. Please refer to Figure 5 As shown, this embodiment discloses another embodiment of the decolorizing pot 110 and the pressure plate 121. The top of the decolorizing pot 110 expands outward to form an expansion edge 112, and at this time, the pressure plate 121 moves down to a position where it fits with the inner wall of the decolorizing pot 110. That is, an injection cavity is formed between the outer wall of the pressure plate 121 and the inner wall of the expansion edge 112 at this time, and then the purified water and the crude chloroquine phosphate are put into the injection cavity, and activated carbon is added for decolorization. When the pressure plate 121 is lifted, the decolorized The...

Embodiment 3

[0059] Considering that the pressure plate 121 will continue to press down, there will be a pressure effect. If the pressure in the concentration pot 130 is controlled by this pressure, the efficiency of crystallization will be greatly improved. Therefore, this embodiment discloses another working mode of the filter element 150, please see Image 6 As shown, the filter element 150 is composed of a filter screen and an outer edge, the outer edge is fitted with the inner wall of the top opening of the concentrating pot 130, and the bottom of the outer edge is annularly provided with a plurality of elastic telescopic rods 151, so as to ensure that the outer edge is not affected by the After force, it can be reset. The specific telescopic rod 151 includes an inner rod and an outer rod, and a spring is arranged between the inner rod and the outer rod. Please refer to Figure 7 As shown, a pressing plate 1211 is provided at the bottom of the pressing plate 121, and the outer diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com