Solar cell and texturing cleaning method thereof

A technology of solar cells and solar panels, applied in the field of solar cells, can solve the problems affecting the efficiency of cells, uneven distribution of suede surface, and reduced lifetime of minority carriers, and achieve the effects of enhancing light trapping effect, reducing surface area, and improving lifetime of minority carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

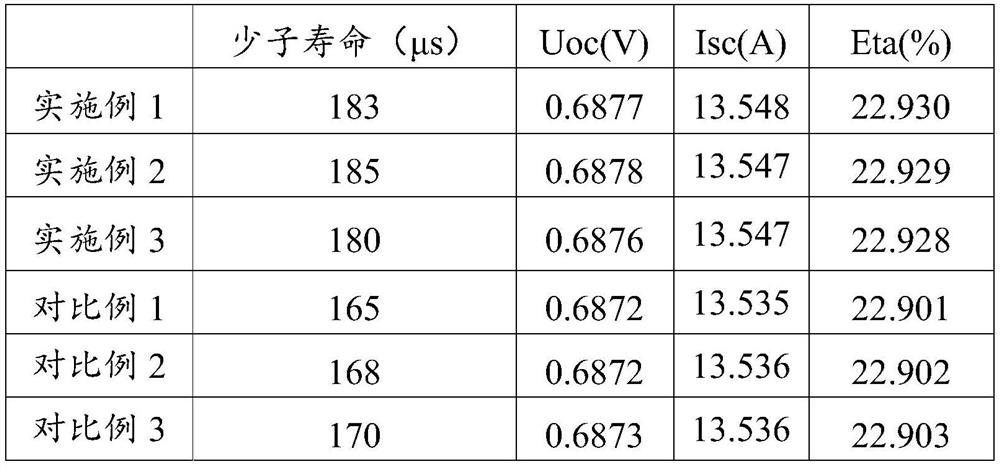

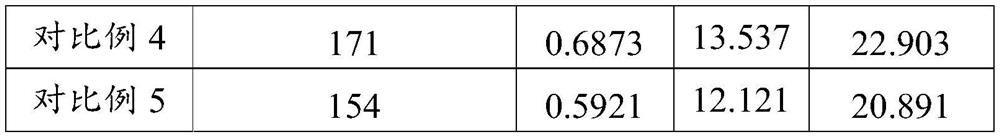

Examples

Embodiment 1

[0061] This embodiment provides a method for making and cleaning solar cells for texturing:

[0062] S1. Remove the contaminants on the surface of the solar cell panel to obtain a first solar cell panel.

[0063] S2, using the first alkali texturing solution at 70°C to perform the first alkali texturing treatment on the first solar cell panel for 300s to obtain a second solar cell panel;

[0064] The first alkaline texturing solution includes a first texturing agent, KOH and deionized water, and the mass ratio of the first texturing agent, KOH and deionized water is 0.7:7:100;

[0065] The first texturing agent comprises in parts by weight: 2 parts of sodium lignosulfonate, 0.002 parts of tartaric acid, 0.003 parts of boric acid and 100 parts of water.

[0066] S3, using the second alkali texturing solution at 70°C to perform the second alkali texturing treatment on the second solar cell panel for 180s to obtain a third solar cell panel;

[0067] The second alkaline texturin...

Embodiment 2

[0075] This embodiment provides a method for making and cleaning solar cells for texturing:

[0076] S1. Remove the contaminants on the surface of the solar cell panel to obtain a first solar cell panel.

[0077] S2, using the first alkali texturing solution at 70°C to perform the first alkali texturing treatment on the first solar cell panel for 300s to obtain a second solar cell panel;

[0078] The first alkaline texturing solution includes a first texturing agent, KOH and deionized water, and the mass ratio of the first texturing agent, KOH and deionized water is 0.7:7:100;

[0079] The first texturing agent comprises in parts by weight: 3 parts of sodium lignosulfonate, 0.005 part of tartaric acid, 0.001 part of boric acid and 100 parts of water.

[0080] S3, using the second alkali texturing solution at 70°C to perform the second alkali texturing treatment on the second solar cell panel for 180s to obtain a third solar cell panel;

[0081] The second alkaline texturing ...

Embodiment 3

[0089] This embodiment provides a method for making and cleaning solar cells for texturing:

[0090] S1. Remove the contaminants on the surface of the solar cell panel to obtain a first solar cell panel.

[0091] S2, using the first alkali texturing solution at 70°C to perform the first alkali texturing treatment on the first solar cell panel for 300s to obtain a second solar cell panel;

[0092] The first alkaline texturing solution includes a first texturing agent, KOH and deionized water, and the mass ratio of the first texturing agent, KOH and deionized water is 0.7:7:100;

[0093] The first texturing agent includes in parts by weight: 1 part of sodium lignosulfonate, 0.001 part of tartaric acid, 0.005 part of boric acid and 100 parts of water.

[0094] S3, using the second alkali texturing solution at 70°C to perform the second alkali texturing treatment on the second solar cell panel for 180s to obtain a third solar cell panel;

[0095] The second alkaline texturing so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com