Flexible sodium ion capacitor electrode material

A capacitor electrode, sodium ion technology, applied in the direction of hybrid capacitor electrodes, capacitors, electrolytic capacitors, etc., can solve the problem of easy powdering of metal bismuth, achieve the best electrical conductivity and mechanical properties, simplify the process flow, and avoid structure powdering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Preparation of nano-bismuth / carbon nanotube two-dimensional thin film anode

[0058] Step 1: Dissolve sodium dodecyl sulfate in 500 mL of deionized water, keeping the concentration of the solution at 1.4 mgmL −1 , and stir with a magnetic stirrer for 30 min.

[0059] Step 2: Add carbon nanotubes to the sodium dodecyl sulfate solution in step 1 at a mass ratio of carbon nanotubes: sodium dodecyl sulfate = 1:2, stir with a magnetic stirrer for 2 h, and then mix The mixed solution was sonicated for 1 h to obtain a carbon nanotube dispersion; the carbon nanotube parameters used in this step were single-walled carbon nanotubes with a length of 10-30 μm.

[0060] Step 3: Use Bi(NO 3 ) 3 ·5H 2 Bi(NO 3 ) 3 ·5H 2 O, add it to the carbon nanotube dispersion obtained in step 2, stir with a magnetic stirrer for 4 h, and then sonicate the mixed solution for 40 min to obtain Bi(NO 3 ) 3 ·5H 2 O / carbon nanotube dispersion.

[0061] Step 4: Place the dispersion obtained i...

Embodiment 2

[0073] The only difference between Example 2 and Example 1 is that the instantaneous heating treatment time is 20 s.

Embodiment 3

[0075] The only difference between Example 3 and Example 1 is that the instantaneous heating treatment time is 25 s.

[0076] The performances of the electrode materials and capacitors prepared in Examples 1, 2, and 3 were tested. The test method for the electrochemical performance of the electrode material is as follows: (1) The electrochemical performance of each embodiment is tested by using a button-type CR2025 battery system (using the Xinwei battery test system, the voltage range is selected as 0.1-3.5 V, the current density is 0.1-5 A g −1 ); (2) assemble the flexible sodium ion capacitor in a glove box using a vacuum plastic bag, and the test conditions are the same as step (1).

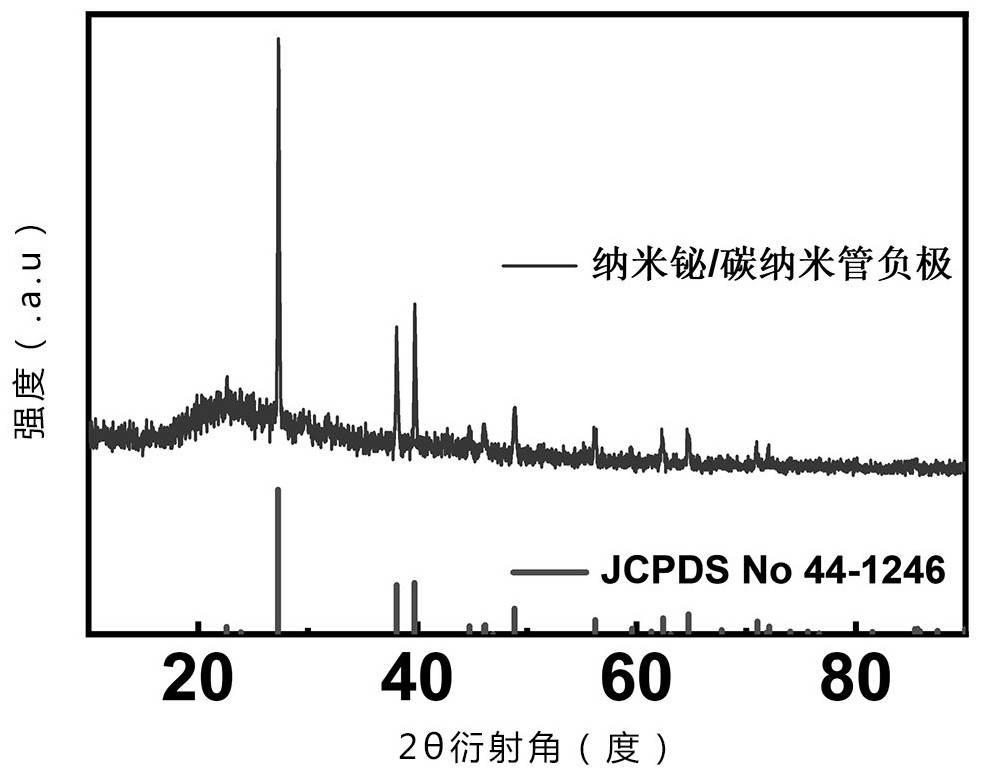

[0077] 1. X-ray diffraction analysis

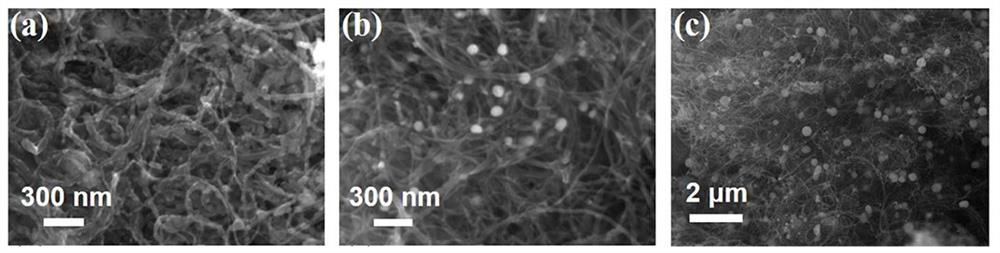

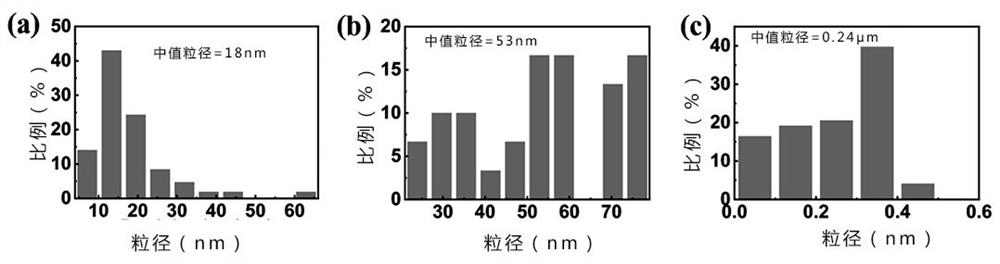

[0078] X-ray diffraction analysis was carried out to the negative electrode material prepared in Example 1, and the results were as follows figure 1 shown. figure 1 This is the X-ray diffraction pattern of the nano-bismuth / carbon nanotube negative el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com