Water lubricated bearing dynamic electromagnetic loading force multi-parameter optimization control system and control method

A technology of water-lubricated bearings and control systems, applied in the general control system, control/regulation system, adaptive control, etc., can solve problems such as unresolved and stable loading force, achieve memory saving, increase stiffness, and expand application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

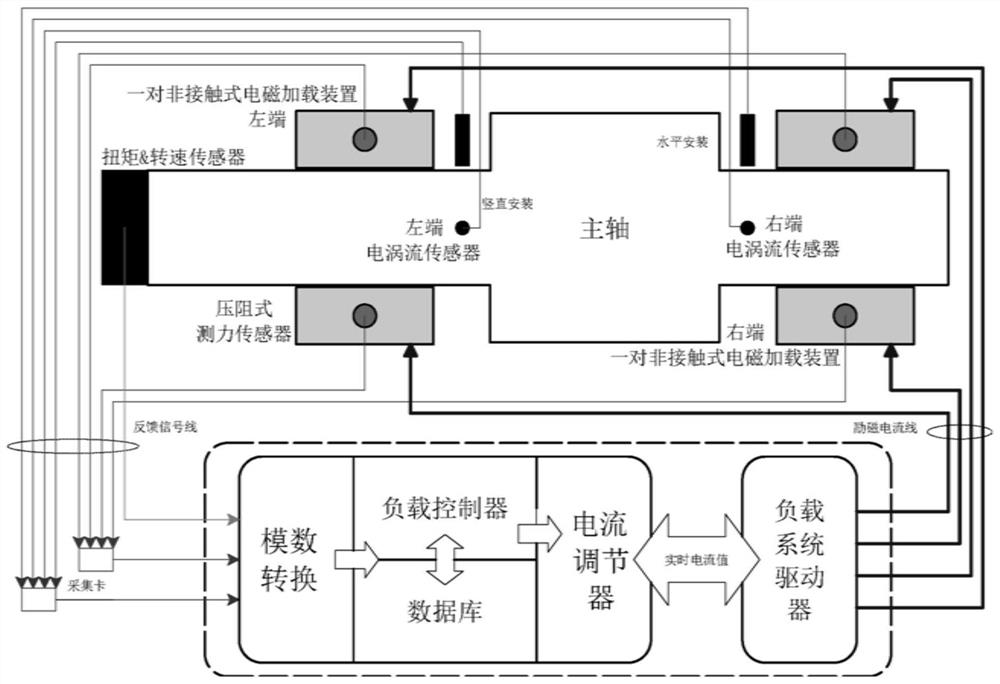

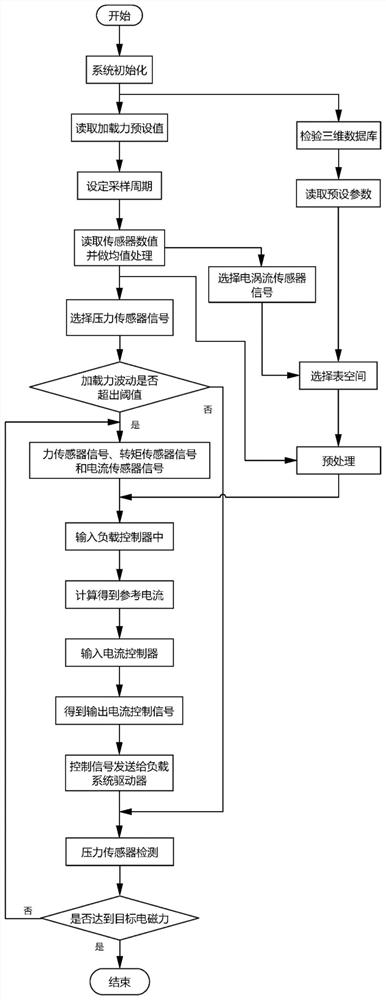

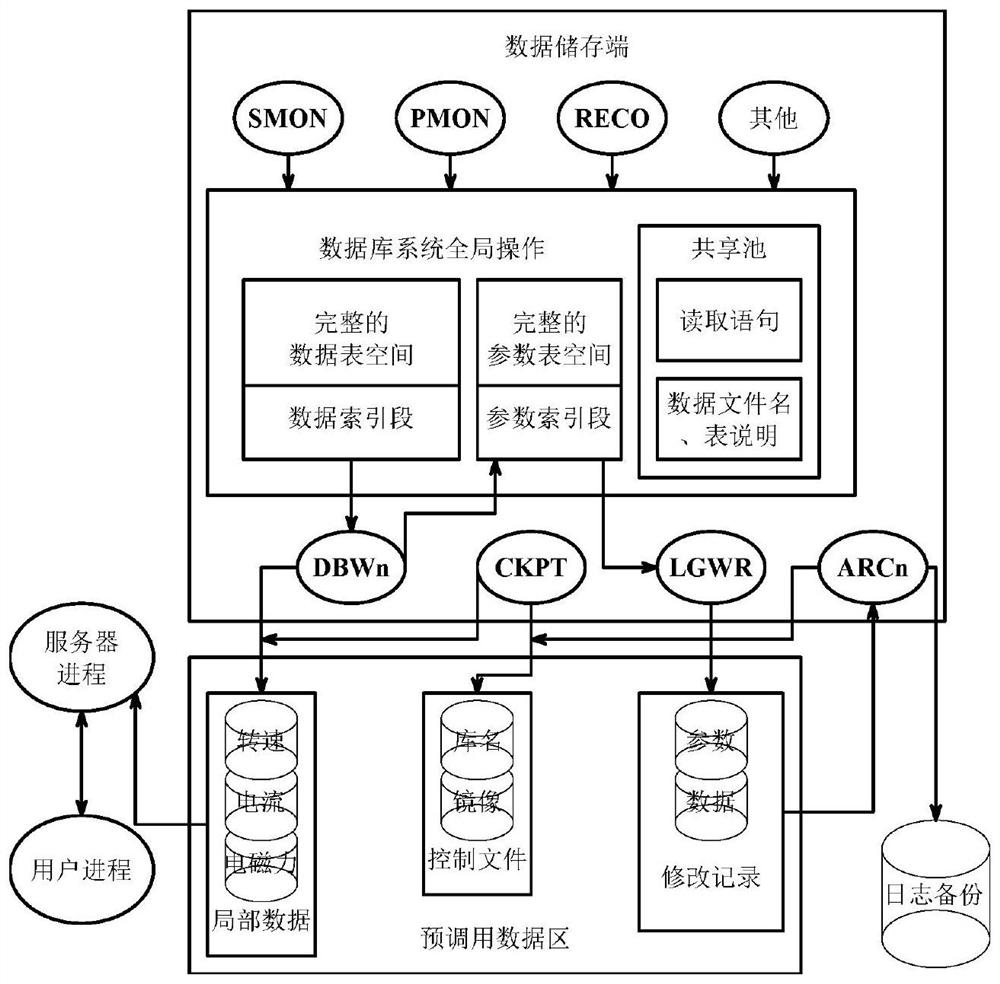

Method used

Image

Examples

Embodiment

[0128] According to the multi-parameter optimization control method of the dynamic electromagnetic loading force of the water lubricated bearing in this embodiment, the target loading force is set, the readings of the torque speed sensor, the piezoresistive load cell, the two pairs of eddy current sensors and the load system controller are collected and the signals are transmitted To the load controller, the load controller reads the sensor readings and performs average processing respectively to obtain the average value of the loading force measurement of the piezoresistive load cell signal. Excitation current measurement average value of the current sensor signal Average value of the speed measurement of the torque speed sensor signal Determine whether the non-contact electromagnetic loading force matches the set value. If it matches, each sensor will continue to repeat the above process; block, the load controller adopts the three-dimensional data path tracking algorith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com