Light-modulated micro-ring resonant cavity and preparation method thereof

A technology of micro-ring resonator and light modulation, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of high process precision, complexity, inability to reconstruct or modify, etc. Simple, Highly Integrated Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

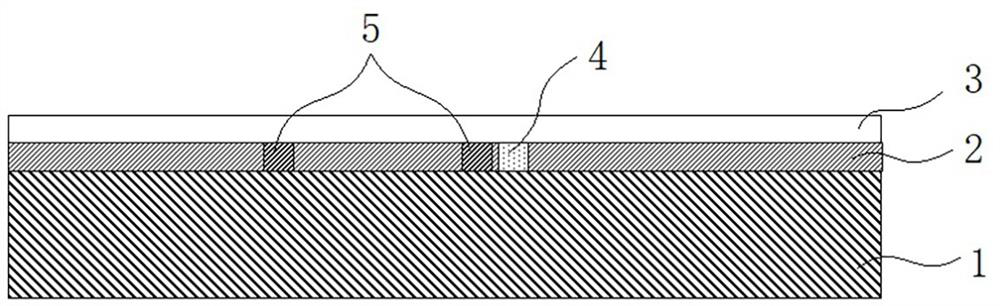

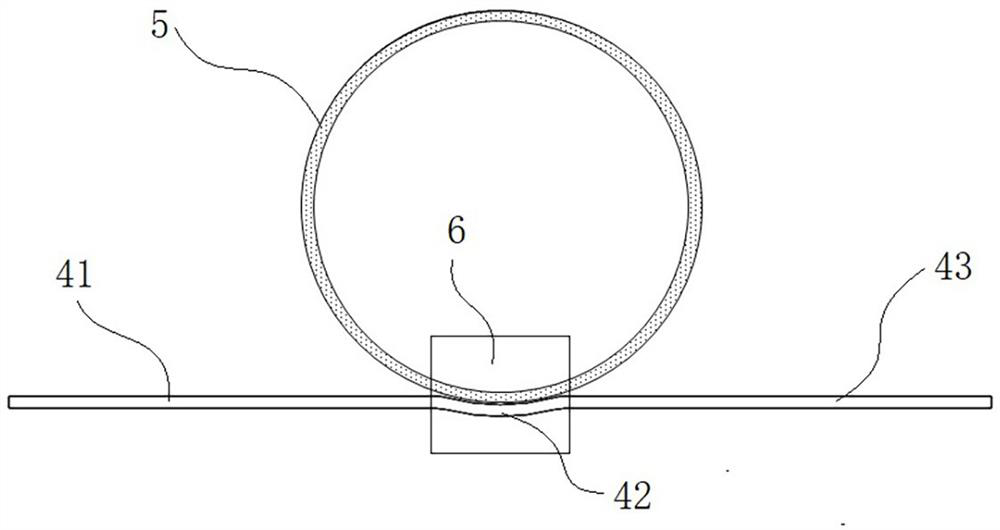

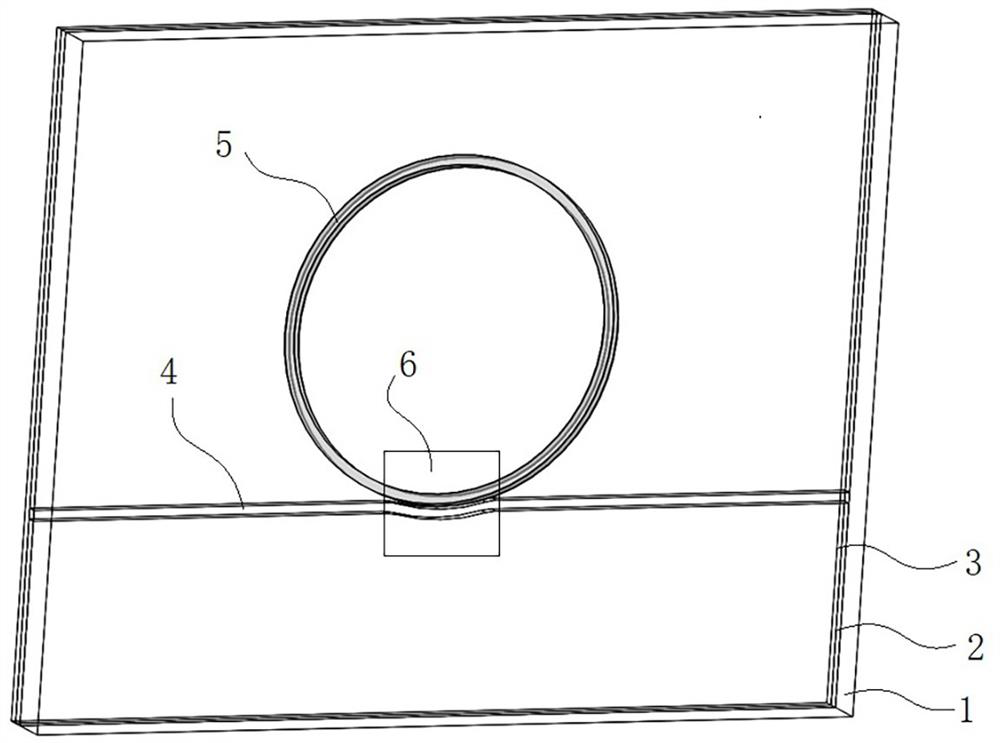

[0038] like Figures 1 to 4 As shown in the figure, an optically modulated microring resonator includes a base layer 1, a microring resonator layer and a cladding film layer in order from bottom to top; a straight busbar waveguide is engraved on the phase change material film 2 by continuous laser direct writing 4 and the annular waveguide 5, the straight busbar waveguide 4 and the annular waveguide 5 are coupled through the coupling region 6. In the present invention, the micro-ring resonator is arranged on the phase-change material film 2, and the micro-ring can be fabricated on the material film by laser by using the material with phase-change characteristics that has a different refractive index from the raw material after being excited by an external excitation signal. The resonant cavity, the material film with the phase change characteristic can realize the reversible change of the crystalline state and the amorphous state under the excitation of the external excitation...

Embodiment 2

[0047] This embodiment provides a method for preparing a light-modulated microring resonator, including the following steps:

[0048] S1. Select the substrate plated with the phase change material film 2 and the cladding film 3 as the base;

[0049] S2. the substrate described in S1 is cleaned;

[0050] S3. Using the external excitation signal to act on the sample, the phase change material film 2 is crystallized according to the structure pattern of the microring resonant cavity to describe the structure of the microring resonant cavity; the phase change material film 2 is excited externally Under the action of signal excitation, the phase transition state of the stress position can be changed; the phase change material film 2 is in an amorphous state without being excited by an external excitation signal, and can be converted from an amorphous state under the excitation of an external excitation signal. Transform into a crystalline state; by adjusting the energy density of ...

Embodiment 3

[0054] This embodiment provides a method for reconstructing a microring resonator. On the basis of Embodiment 2, when the structure of the prepared microring resonator needs to be reconstructed, a femtosecond laser is used to reconstruct the prepared microring resonating cavity. The crystallized region is de-crystallized, and then step S3 in Example 1 is repeated to realize the reconstruction of the microring resonant cavity structure. Specifically include:

[0055] Replace the processing laser used in Example 1 with a femtosecond laser with high energy; use a fixture to fix the sample to be processed (the microring resonator prepared in Example 1) on the working distance plane of the objective lens, and move the displacement The stage aligns the sample marks to ensure that the sample position is in the same position twice;

[0056] Input the structure pattern of the microring resonator to be reconstructed into the control program of the laser processing platform. First, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com