Spring needle mounting and positioning structure for chip testing equipment

A chip testing, installation and positioning technology, applied in measuring devices, parts of electrical measuring instruments, measuring electricity, etc., can solve problems such as short-circuit links, blockages, increase the complexity of the pogo pin welding process, and reduce production conditions. , avoid positioning problems, improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

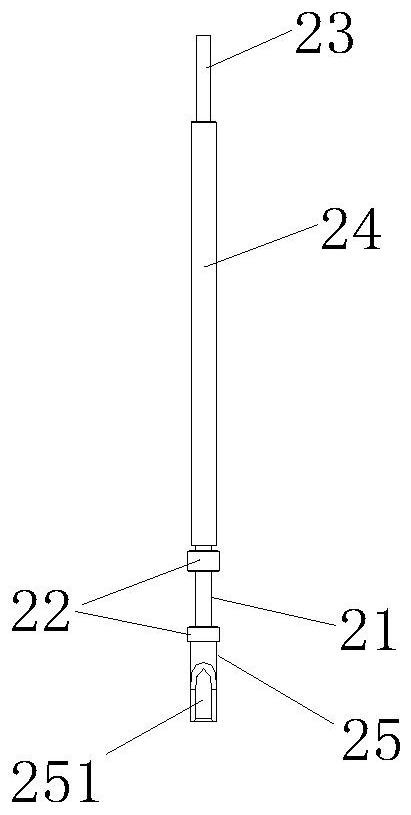

[0040] Example 1, attached figure 1It is a schematic structural diagram of the pogo pin 2 in the patented structure of the present invention, which consists of four parts, a tail structure 25, a sleeve 24, a probe head 23 and a spring (not shown in the figure), and the spring is installed inside the sleeve 24. , in contact with the bottom of the probe head 23; the tail structure 25 and the sleeve 24 are connected together by a round riveting point; the spring is loaded into the sleeve 24 and can be freely compressed in the sleeve 24; the head of the probe head 23 It is relatively thin, protrudes from the outside of the sleeve 24, and the bottom is thicker. It is installed inside the sleeve 24. The bottom of the probe head 23 is in contact with the spring, and the connection between the thickness of the probe head 23 forms a step. When the mouth is closed, the crimped edge is pressed on the step of the probe head 23, so that the probe head 23 is enclosed in the sleeve 24, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com