Welding strain gauge curing device and process

A welding strain and curing device technology, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of no clear operating instruments and methods, and achieve the effects of improving measurement performance, convenient use, and improving specifications and standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

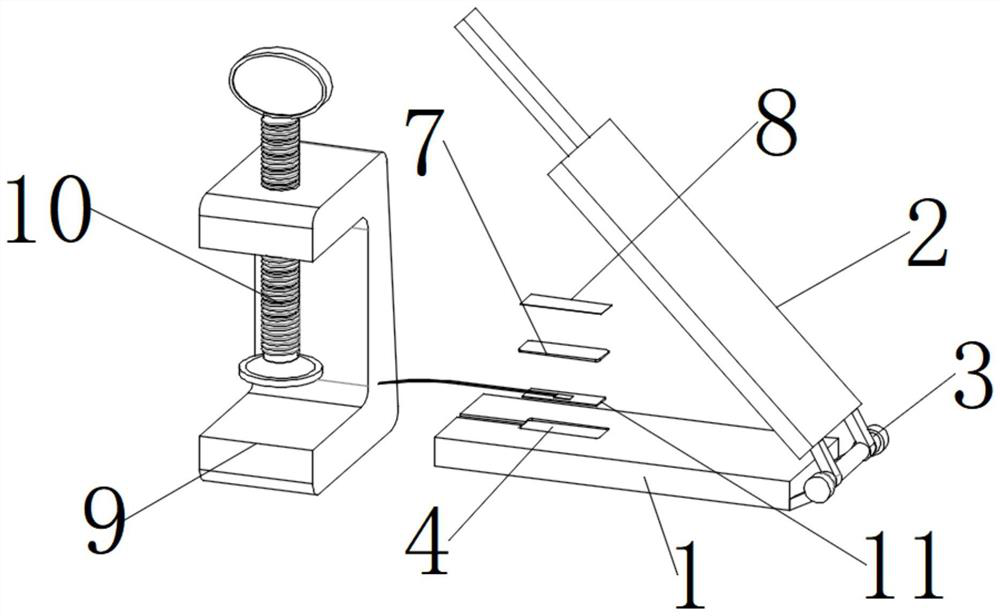

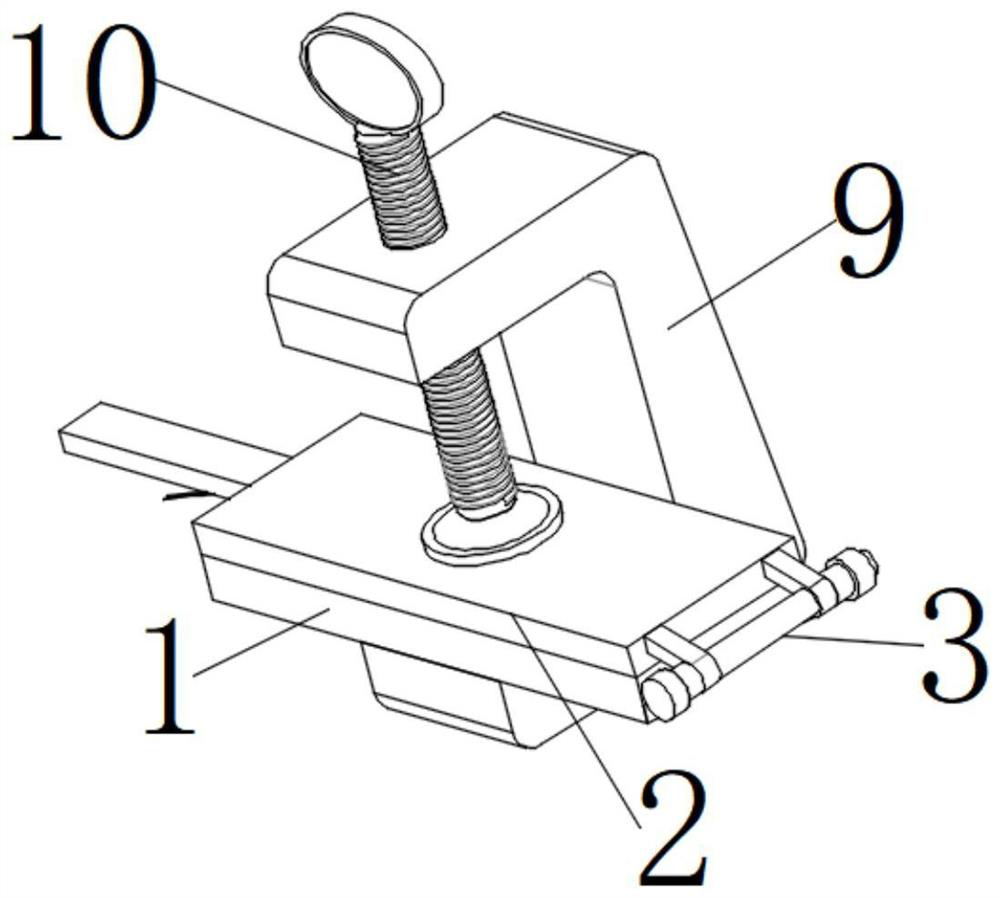

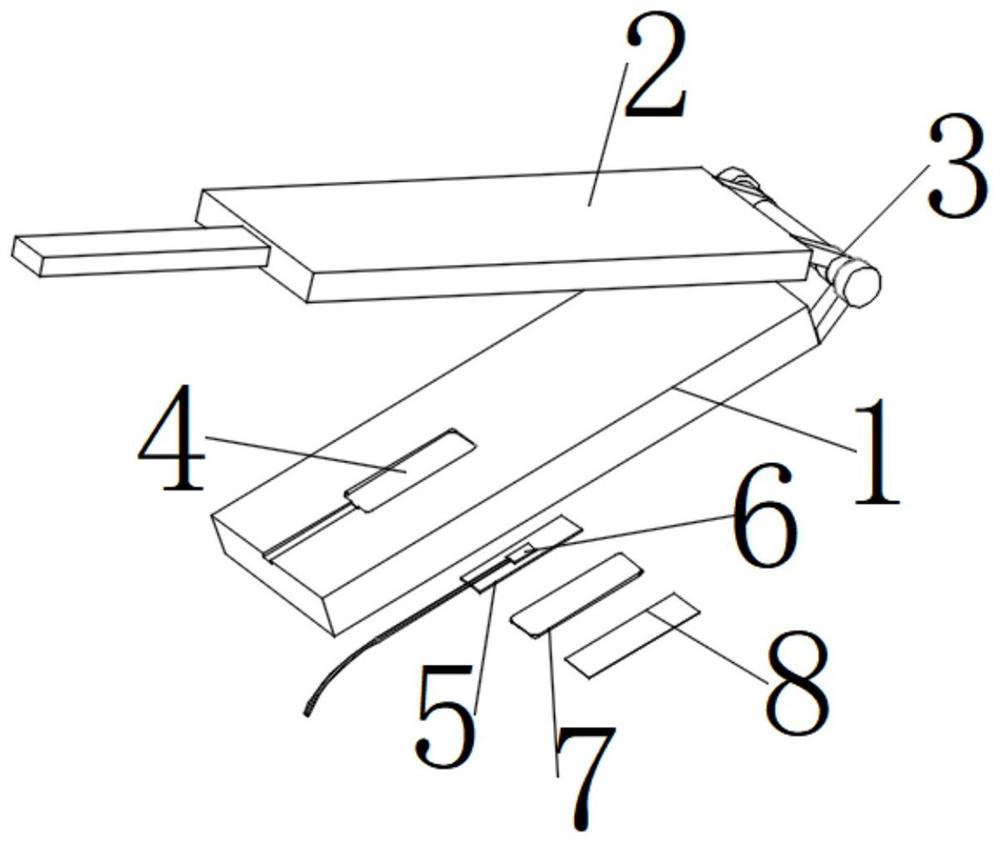

[0033] like Figure 1-3 As shown in the figure, the embodiment of the present invention provides a welding strain gauge curing device, including a welding strain gauge clamping template and a pressure pedestal. Rotating around the axis, it is very convenient to open and close, so that the lower bottom plate 1 and the upper top plate 2 fit tightly when they are attached. The size of 4 is consistent with the size of the welding strain gauge 11, and grooves 4 of different sizes and shapes can be engraved on the same lower bottom plate 1. The groove 4 is processed by the engraving process, and the welding strain gauge 11 is placed inside the groove 4. , the welding strain gauge 11 includes a thin stainless steel substrate 5, a resistance strain gauge sensing element 6, and the resistance strain gauge sensing element 6 is fixed and connected to the thin stainless steel substrate 5 by a long-term high-performance two-component epoxy resin adhesive H-610 , the upper surface of the w...

Embodiment 2

[0036] The key to the pressure curing process is the reasonable control of pressure, temperature and time.

[0037] The welding strain gage curing process includes the following steps:

[0038] S1. Placement

[0039] Paste the resistance strain gauge sensing element 6 on the thin stainless steel substrate 5, place the preliminarily bonded thin stainless steel substrate 5 and the resistance strain gauge sensing element 6 in the groove 4, and place a layer of polytetrafluoroethylene on the top. Film 7, then install the plastic groove substrate 8, and attach the lower bottom plate 1 and the upper top plate 2, and place them on the U-shaped platform 9;

[0040] S2. Perform initial solidification

[0041] By rotating the pressurizing threaded rod 10, the pressure is increased to make the pressure reach 0.1-0.3MPa, and then the device is put into a temperature box, the temperature is 120 ° C, and the temperature is kept for two hours;

[0042] S3. Subsequent processing

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com