Cotton fabric printing, dyeing and desizing pretreatment equipment and pretreatment process

A cotton fabric and pretreatment technology, applied in the field of cotton fabric printing, dyeing, desizing pretreatment equipment and pretreatment technology, can solve problems such as unfavorable improvement of desizing process efficiency, weakening of desizing treatment effect, affecting enzyme catalytic activity, etc. The effect of stacking reaction time, improving cleaning effect, and improving padding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

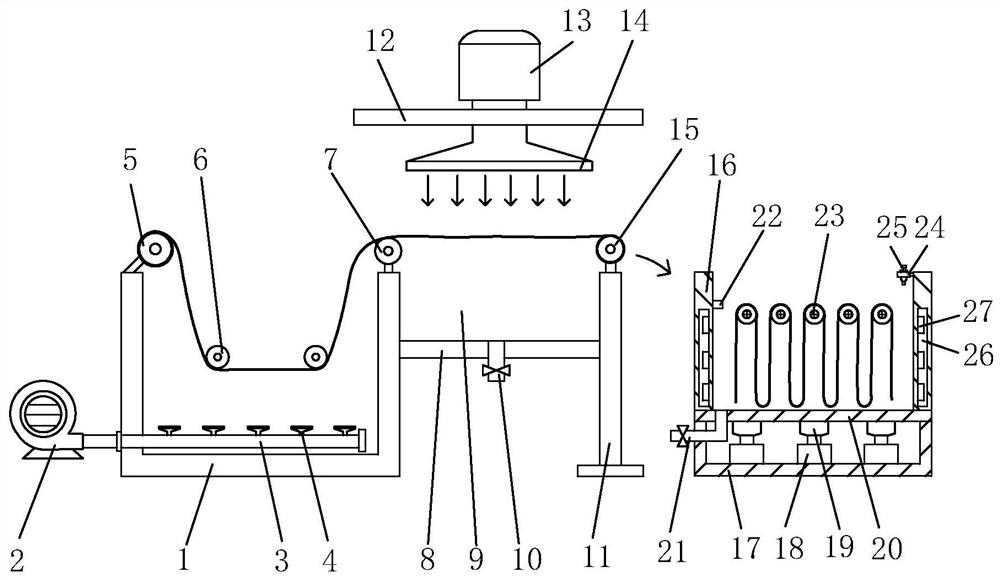

[0028] A cotton fabric printing, dyeing and desizing pretreatment equipment, such as figure 1 As shown, it includes a pre-washing box 1, and the pre-washing box 1 contains warm water for pre-washing cotton fabrics.

[0029] In order to improve the pre-cleaning effect of cotton fabrics, the impurities attached to the surface of cotton fabrics can be removed more efficiently. figure 1 As shown, an air passage 3 is horizontally arranged in the bottom of the pre-water washing box 1, the air passage 3 extends to the outside of the pre-water washing box 1 and is connected with a blower 2, and a plurality of suspensions connected to the air passage 3 are arranged on the air passage 3 Sprinkler 4. The blower 2 is used to introduce gas, and the fine air bubbles produced by the suspending nozzle 4 enter the warm water to form an air flotation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com