Method for preparing nano cuprous oxide by using copper-containing waste mobile phone circuit board as raw material

A technology of nano-cuprous oxide and waste printed circuit, which is applied in the field of preparing nano-cuprous oxide, and achieves the effects of high yield, mild reaction process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

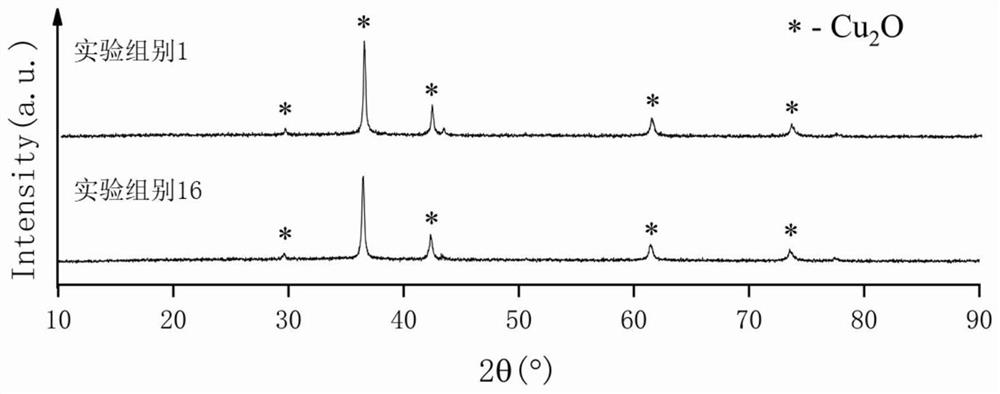

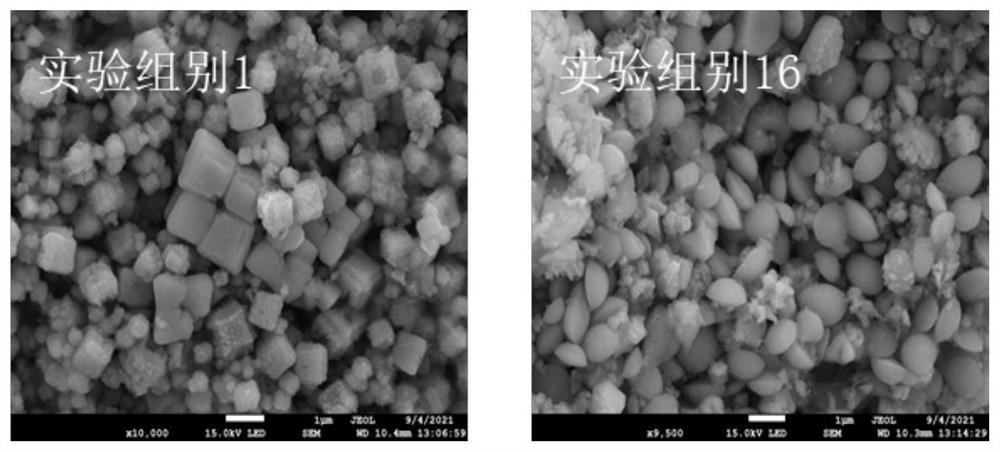

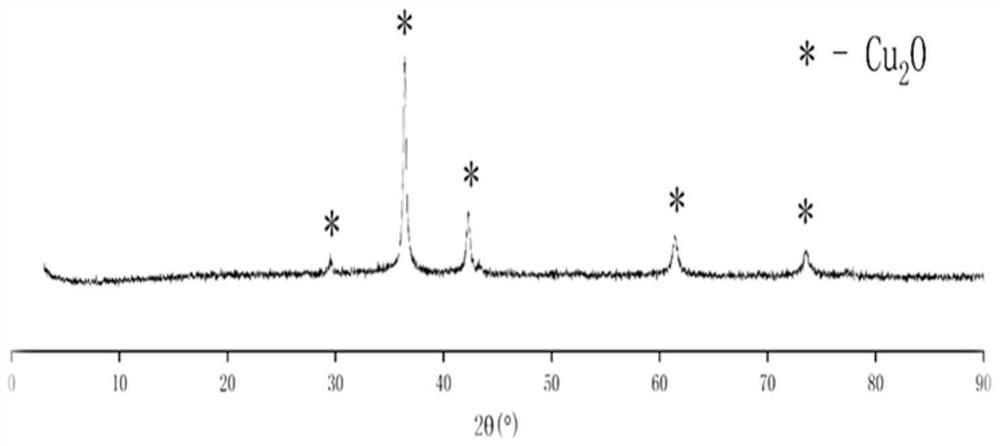

Examples

Embodiment 1

[0028] 1) Simulation experiment design steps:

[0029] Emulsion Membrane Extraction Steps

[0030] 1) Accurately weigh copper nitrate, and use ultrapure water to prepare a simulated solution with a copper content of 1000-5000 ppm for use.

[0031] 2) Take quantitative surfactant Span 80 2-10%, carrier Lix984 2%-10%, liquid paraffin 1-5%, membrane solvent kerosene 75-95ml, mix well, then add an equal volume of 3%-9W% ascorbic acid solution , the emulsification reaction is carried out by high-speed stirring, the rotating speed is 3000-4000r / min, and the stirring time is 10-25min to obtain an emulsion.

[0032] 3) Adjust the pH of the simulated solution to 7-9, add the emulsion, the volume ratio of the emulsion to the simulated solution is 1:3-5, stir rapidly, the rotation speed is 300-400r / min, the stirring time is 5-15min, and then quickly transfer to In the separatory funnel, let stand for stratification, the upper layer is the emulsion after extraction, and the lower layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com