Manufacturing method of double-layer multi-color multi-physical-property foaming product

A technology of foamed products and production methods, which is applied in the field of foamed products, can solve the problems of molds that do not have the ability to exclude air, bulges on the soles, and insufficient hardness, etc., so as to improve the yield of soles, reduce the rate of defective products, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

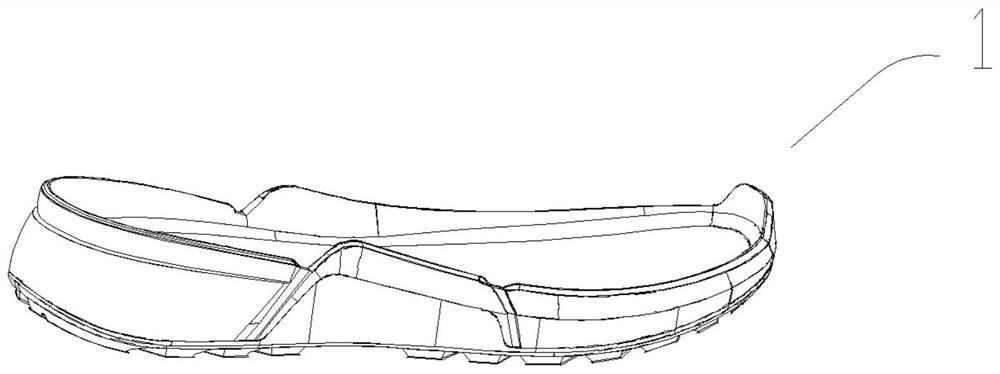

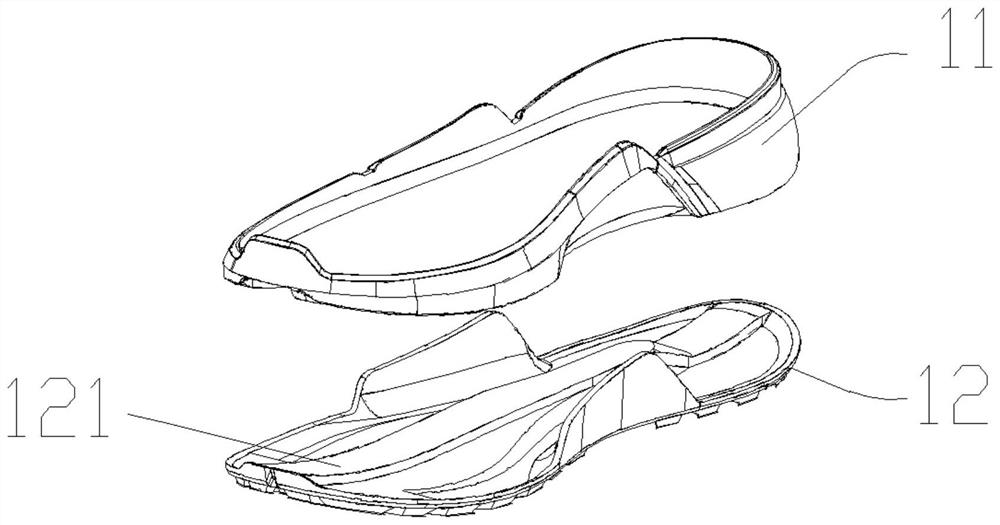

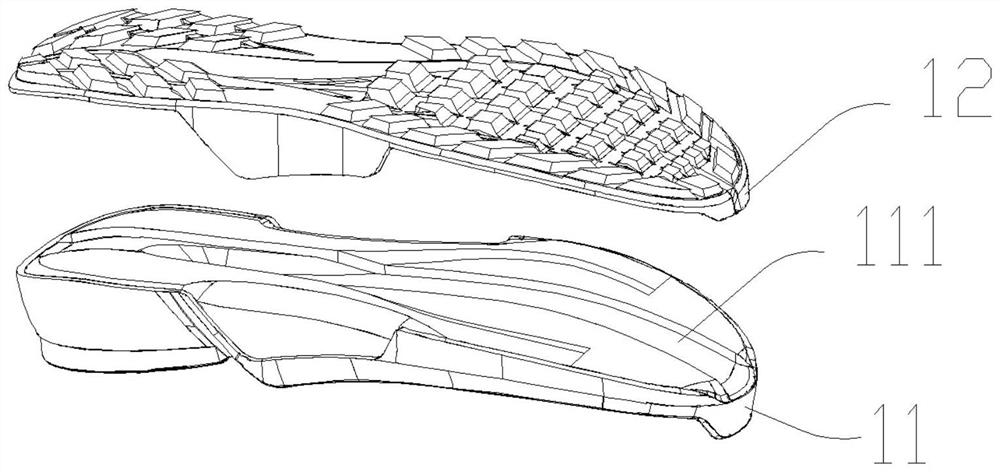

[0027] see Figure 1-4 As shown, the present invention relates to a double-layer multi-color multi-physical foam sole 1, comprising an upper sole 11 and a lower sole 12, a plurality of ventilation holes are distributed on the upper surface of the upper sole 11, and the upper sole 11 and the lower sole 12 12 is made of foam material, the grounding surface of the lower sole 12 is provided with at least one kind of high anti-skid shading structure in rhombus, cross pattern and suction cup pattern, and the upper surface of the lower sole 12 is provided with extending from the forefoot to the heel. The arc-shaped protrusion 121, the lower surface of the upper sole 11 is provided with a slot hole 111 at a position corresponding to the arc-shaped protrusion 121, the slot hole extends along the length direction of the sole, and the depth of the slot hole 111 at the heel position is greater than the depth at the front and rear positions. Large, the slot 111 increases the flexibility of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com