Intelligent welding seam shot blasting machine

A shot blasting machine and shot blasting machine technology, which is applied in abrasive jet machine tools, metal processing equipment, used abrasive processing devices, etc. problems, to achieve the effect of improving shot blasting efficiency and shot blasting effect, improving the degree of intelligence, and improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

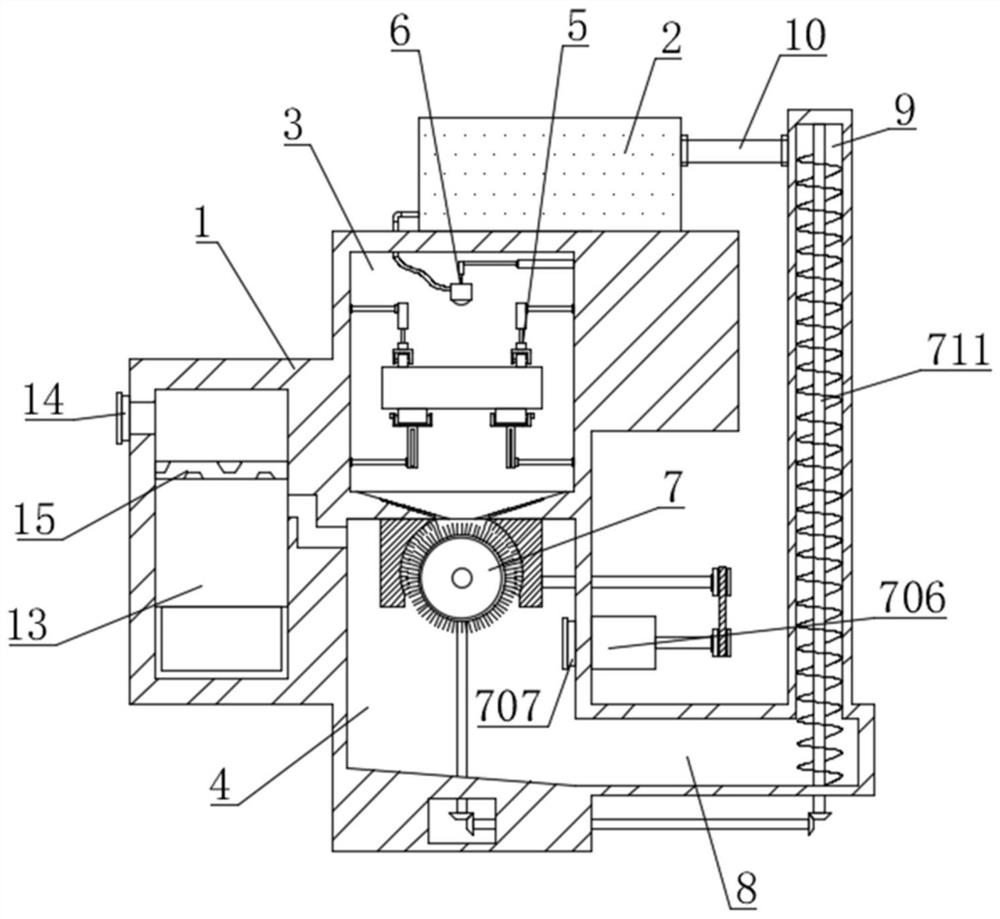

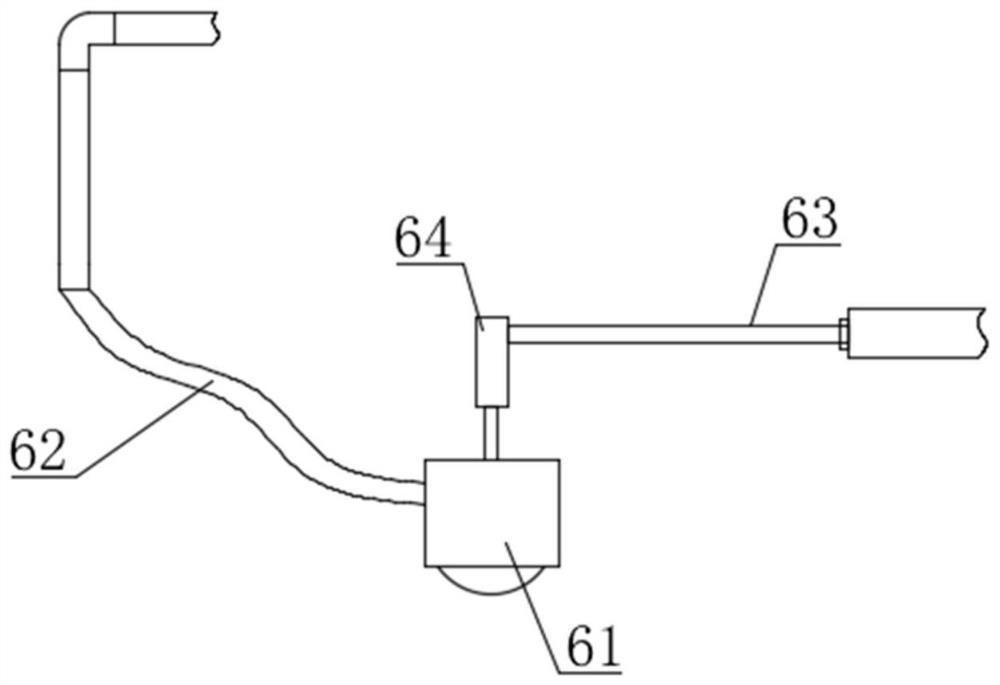

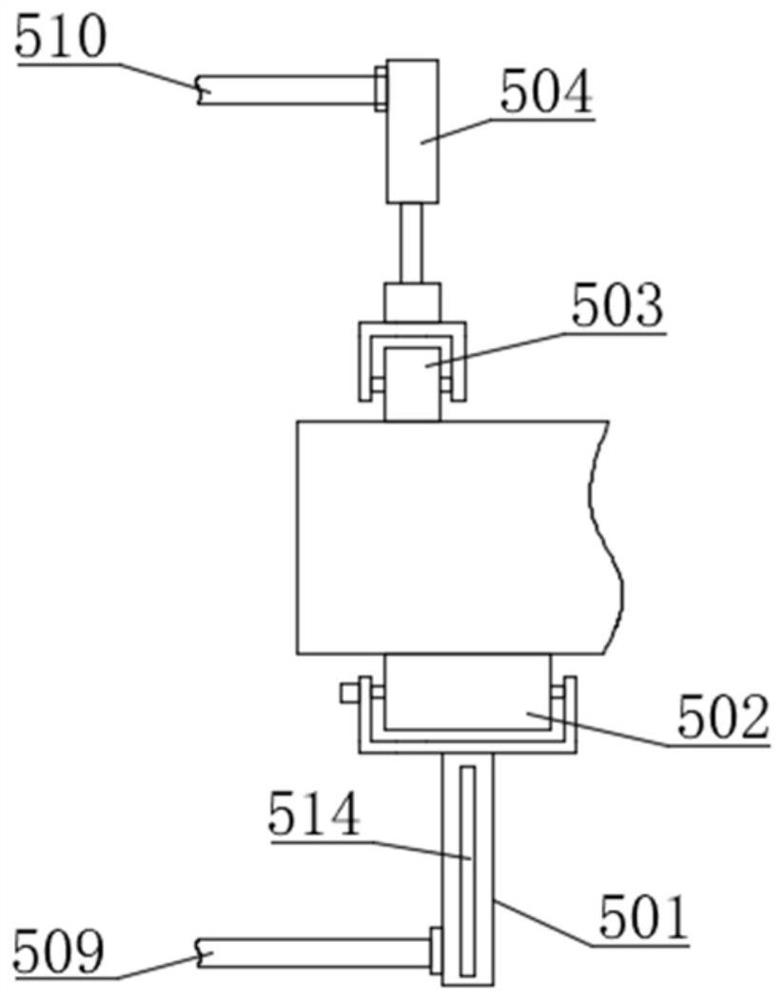

[0048] like Figure 1-9 As shown in the figure, an intelligent weld shot blasting machine proposed by the present invention includes a shot blasting machine body 1, the top of the shot blasting machine body 1 is fixedly installed with a shot blasting box 2 by bolts, and the shot blasting box 2 stores a shot blasting machine. The shot blasting machine body 1 is provided with a shot blasting room 3 and a clean room 4, and the shot blasting room 3 is located above the clean room 4 and communicated with it through the lower hopper 11, and the lower hopper 11 is provided with a feeding plate 12. The shot blasting chamber 3 is provided with a shot blasting device 6. Specifically, the shot blasting device 6 includes a shot blasting head 61, a lateral push rod 63 and a lifting push rod 64. The lateral push rod 63 is arranged in the shot blasting chamber 3, and the The push rod 64 is connected to the horizontal push rod 63 and the shot peening head 61 , and the shot peening head 61 and...

Embodiment 2

[0055] like Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that a control panel is installed on the shot blasting machine body 1, and the control panel includes a data acquisition unit, a processor, a material removal analysis unit, a diagnosis adjustment unit and an intelligent control unit; The collection unit collects the clearing data, and sends the clearing data to the processor; wherein, the clearing data includes the pressure value of the receiving plate 12 (the pressure value is the weight of the pellets carried above the receiving plate 12, which is determined by the It is detected by the gravity sensor) and the ejection speed value of the shot blasting machine 6 (the ejection speed value is the ejection speed of the shot material during shot blasting, which is detected by the ejection speed sensor), and the processor generates a clearing analysis signal of the returned material, and the The clearing analysis signal and clearing data a...

Embodiment 3

[0062] like Figure 10 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the control panel further includes a diagnosis and adjustment unit, and the data acquisition unit collects the diagnosis data, and sends the diagnosis data to the processor; wherein, the diagnosis data includes a shot blasting machine. The throwing distance value of 6 and the injection speed value of the shot blasting machine 6; the processor generates the adjustment analysis signal of the shot blasting machine, and sends the adjustment analysis signal and the diagnosis data to the diagnosis analysis unit; the diagnosis analysis unit is used for adjustment analysis, adjustment The analysis process is as follows:

[0063] Step X1: Receive the throw distance value of the shot blasting wheel 6, and mark the throwing distance value of the shot blasting wheel 6 as PJZ; wherein, the throwing distance value of the shot blasting wheel 6 represents the distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com