Novel mixer suitable for mixing high-viscosity fluid

A fluid mixing and mixer technology, used in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of high cost, high pressure drop, long time and channel length, etc., to increase disturbance and reduce flow resistance. , the effect of lengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: CFD calculation simulates the effect of mixer baffle cycle number N on mixing

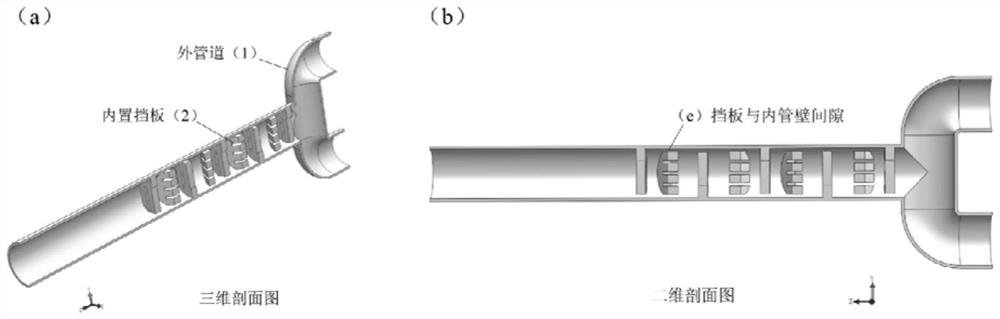

[0031] like Figure 1 to Figure 3 As shown, the novel mixer suitable for mixing high viscosity fluids includes an outer pipe 1 and a "comb"-shaped built-in baffle 2 located in the outer pipe; the outer pipe 1 includes two inlets, an outlet and a mixing channel. .

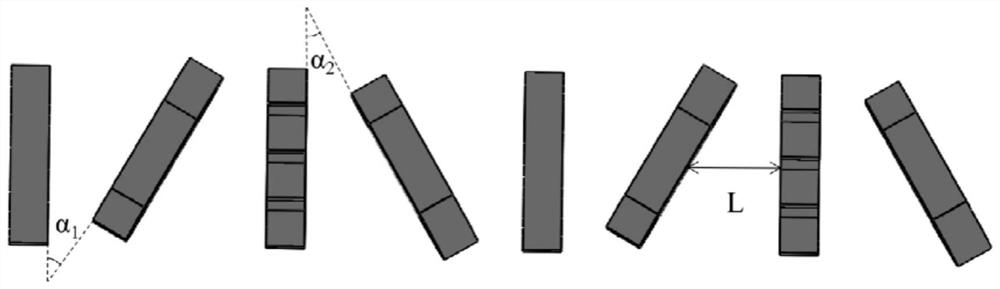

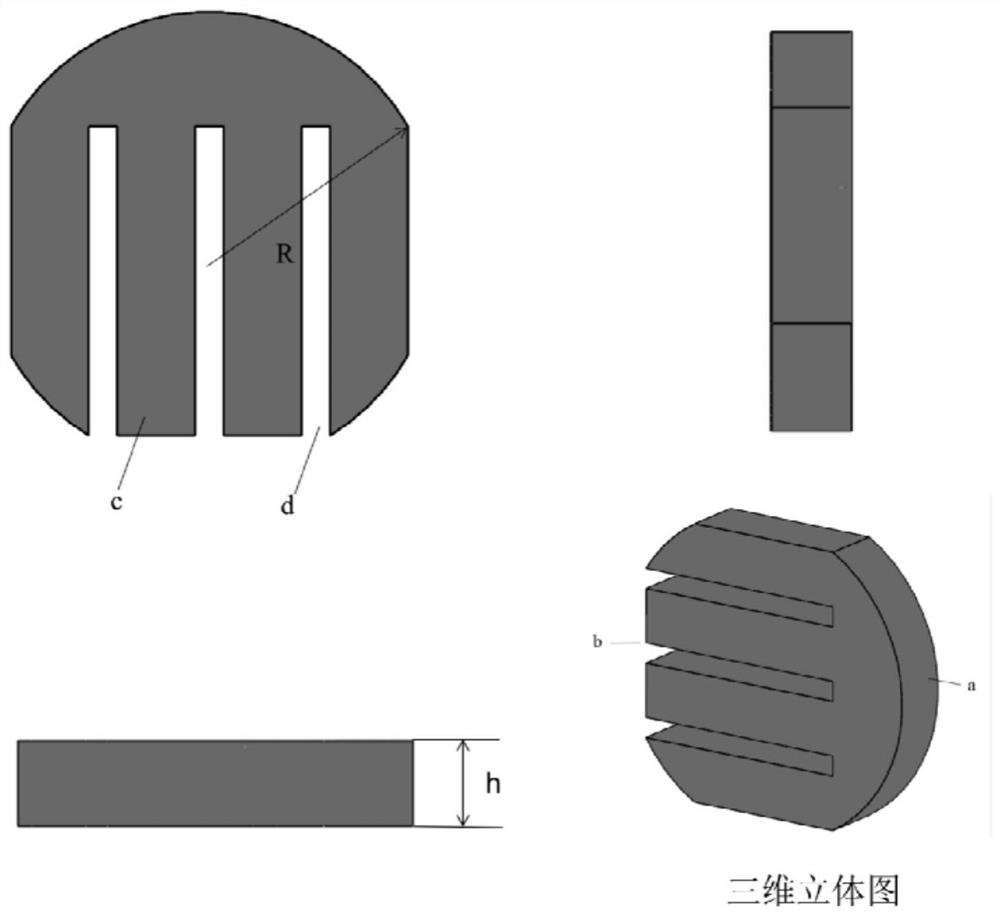

[0032] Among them, the built-in baffles 2 are arranged periodically along the axial direction of the pipeline, and the two sides of each baffle are fixedly connected with the inner wall of the mixing channel; The other side is provided with a comb-tooth-shaped through groove;

[0033] figure 1 A schematic cross-sectional view of the mixer structure is given, in which (a) is a three-dimensional cross-sectional view of the mixer, and (b) is a two-dimensional cross-sectional view of the mixer.

[0034] figure 2 A top view of the periodic arrangement of the built-in baffles 2 is given. The mixing channel is arranged ...

Embodiment 2

[0037] Example 2: Application of Reactor—CFD Computational Simulation to Prepare Biodiesel

[0038] Select the size of the reactor: the outer diameter is 17mm, the inner diameter is 16mm, the length of the mixing channel is 250mm, the built-in "comb" baffle has 4 comb teeth, the length of the comb teeth is 11mm, the width is 1mm, and the thickness is 4mm. The radius of one side of the arc is 8mm, the baffle spacing is 2.5mm, ∠α 1 =∠α 2 =30°, the number of baffle periods is 3. The mixer was numerically calculated with ANSYS software, and the three-dimensional model of the mixer was imported into fluent in Workbench for simulation. Under the condition of Reynolds number Re=81.4, the density of soybean oil is selected as 894.1kg·m -3 , the density of methanol is 755kg m -3 , the diffusion coefficients are both 8.13×10 -10 m 2 ·s -1 , the viscosity is 17.5mPa s, the inlet flow velocity is 0.05m s -1 . Get the mixed effect diagram as Figure 5 (a), the mixing efficiency at ...

Embodiment 3

[0039] Example 3: Application of Reactor—CFD Computational Simulation to Prepare Biodiesel

[0040] Select the size of the reactor: the outer diameter is 17mm, the inner diameter is 16mm, the length of the mixing channel is 250mm, the built-in "comb" baffle has 4 comb teeth, the length of the comb teeth is 11mm, the width is 1mm, and the thickness is 4mm. The radius of one side of the arc is 8mm, the baffle spacing is 2mm, ∠α 1 =∠α 2 =30°, the number of baffle periods is 3. The mixer was numerically calculated with ANSYS software, and the three-dimensional model of the mixer was imported into fluent in Workbench for simulation. Under the condition of Reynolds number Re=8.6, the density of soybean oil is selected as 894.1kg·m -3 , the density of methanol is 755kg m -3 , the diffusion coefficients are both 8.13×10 -10 m 2 ·s -1 , the viscosity is 200mPa s, the inlet flow velocity is 0.06m s -1 . Get the mixed effect diagram as Figure 5 (b), calculate the mixing effici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com