Super-hydrophobic coating based on compounding of carbon nano tube and silicon dioxide and preparation method of super-hydrophobic coating

A technology of super-hydrophobic coating and silicon dioxide, applied in the direction of coating, etc., can solve the problems of high energy consumption, difficulty in removing ice layer, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix 60 parts of solvent, 1 part of dispersant, and 10 parts of fluorosilicone resin, and use zirconium dioxide as grinding beads to carry out sand grinding at room temperature for 5 minutes;

[0028] (2) adding 1 part of hydrophobic carbon nanotubes and 5 parts of hydrophobic nano-silicon dioxide to the mixed solution obtained in (1), and continued sanding for 10 min at room temperature;

[0029] (3) filter out the sand-milled slurry to obtain a filtrate;

[0030] (4) The filtrate is coated on the surface of the material, and after being placed at room temperature for 30 minutes, a composite superhydrophobic coating of hydrophobic nano-silica and hydrophobic carbon nanotubes can be obtained.

Embodiment 2

[0032] (1) Mix 70 parts of solvent, 2 parts of dispersant, and 15 parts of fluorosilicone resin, and use zirconium dioxide as grinding beads to carry out sand grinding at room temperature for 8min;

[0033] (2) adding 3 parts of hydrophobic carbon nanotubes and 10 parts of hydrophobic nano-silicon dioxide to the mixed solution obtained in (1), and continuing sand grinding for 15min at room temperature;

[0034] (3) filter out the sand-milled slurry to obtain a filtrate;

[0035] (4) The filtrate is coated on the surface of the material, and after standing at room temperature for 40 min, a composite superhydrophobic coating of hydrophobic nano-silica and hydrophobic carbon nanotubes can be obtained.

Embodiment 3

[0037] (1) Mix 80 parts of solvent, 5 parts of dispersant, and 20 parts of fluorosilicone resin, and use zirconium dioxide as grinding beads to carry out sand grinding at room temperature for 10 minutes;

[0038] (2) adding 5 parts of hydrophobic carbon nanotubes and 20 parts of hydrophobic nano-silicon dioxide to the mixed solution obtained in (1), and continuing sand grinding at room temperature for 20min;

[0039] (3) filter out the sand-milled slurry to obtain a filtrate;

[0040] (4) The filtrate is coated on the surface of the material, and after being placed at room temperature for 50 min, a composite superhydrophobic coating of hydrophobic nano-silica and hydrophobic carbon nanotubes can be obtained.

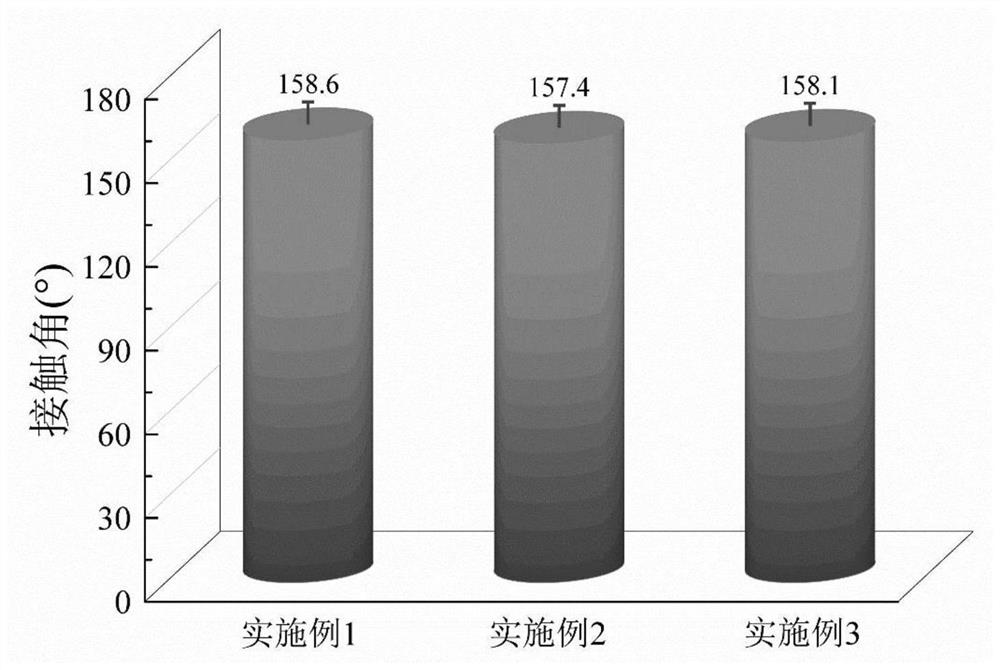

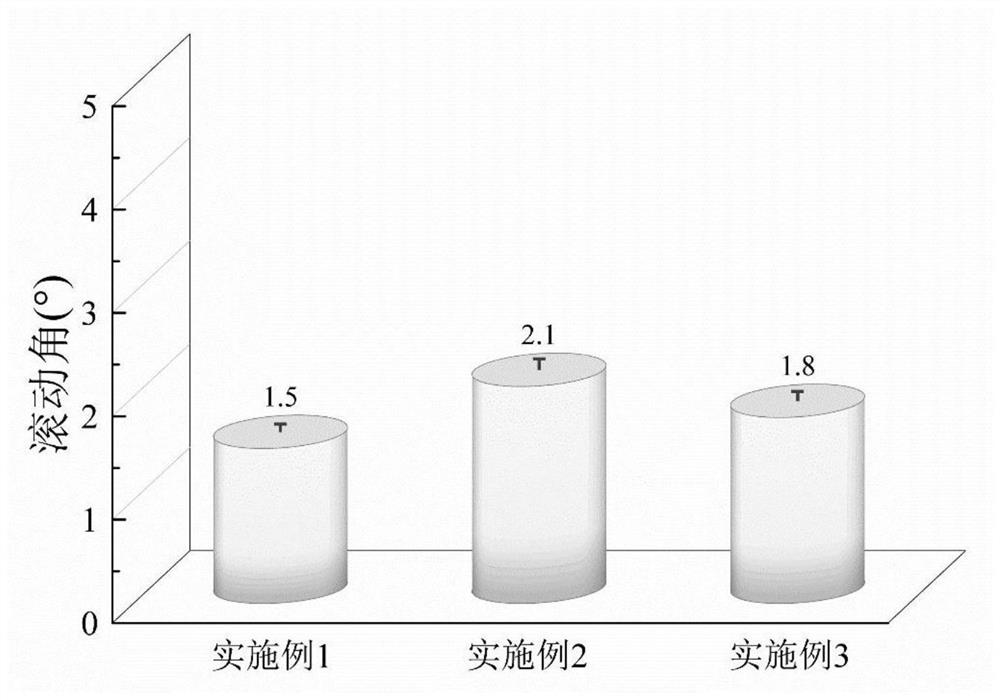

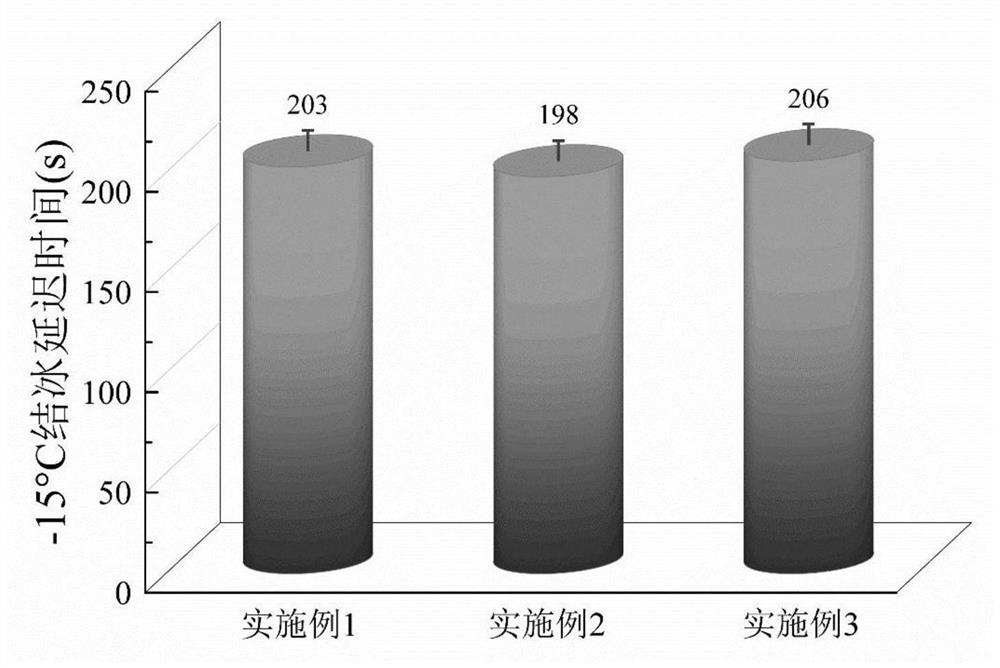

[0041] It can be seen from the data in the figure that the coating prepared by the present invention has good superhydrophobicity, can significantly prolong the freezing time, and has low ice layer adhesion, indicating that it has good anti-icing / deicing performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com