Breakdown voltage testing device for lithium ion battery diaphragm

A lithium-ion battery, breakdown voltage technology, applied in the direction of material breakdown voltage, measuring device casing, testing dielectric strength, etc., can solve the problems of unfavorable disassembly work, difficult disassembly, easy to drop and close, etc., to ensure the stability of opening , Improve the flexibility of use and prevent the effect of self-closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

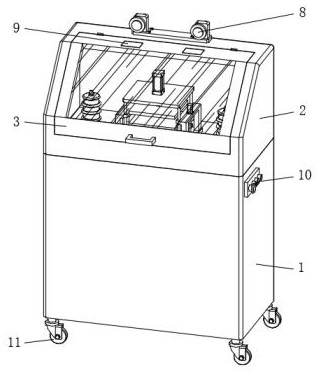

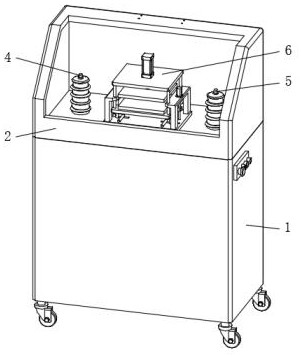

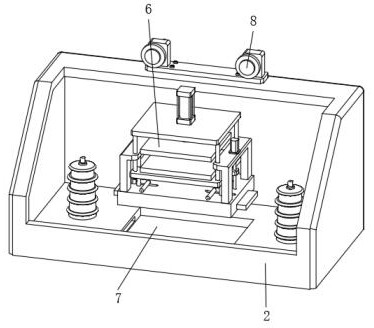

[0031] like Figure 1-Figure 8 As shown, a breakdown voltage test device for a lithium ion battery diaphragm includes a base 1, a test box 2 is arranged on the upper end of the base 1, and a protective cover 3 is connected to the test box 2, and a first test box 2 is installed inside the test box 2. Terminal 4, and a second terminal 5 is arranged inside the test box 2, an adsorption plate 9 is fixedly installed on the protective cover 3, an installation groove 7 is opened at the inner bottom end of the test box 2, and the inner bottom end of the test box 2 is provided with a mounting groove 7. There is an installation structure 6, a fixing frame 8 is fixedly installed on the top of the test box 2, the base 1 and the test box 2 are fixedly connected, and a controller 10 is installed on the base 1, and the corners of the lower surface of the base 1 are provided with Universal wheel 11, and the universal wheel 11 and the base 1 are fixedly connected, the controller 10 is provided...

Embodiment 2

[0034] like Figure 1-Figure 8 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is: Figure 4 , 5 , 6, the installation structure 6 includes a clamping frame 601, an adjustment frame 602, a first metal plate 604 and a second metal plate 607, the adjustment frame 602 is installed on the clamping frame 601, and the clamping frame 601 is installed in the test box At the inner bottom end of 2, the first metal plate 604 and the second metal plate 607 are connected to the adjustment frame 602, the installation structure 6 also includes a supporting bottom plate 603, a supporting top plate 605 and a cylinder 606, and the clamping frame 601 is clamped in the installation groove 7 Among them, the first metal pl...

Embodiment 3

[0037] like Figure 1-Figure 8 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the third embodiment and the first embodiment is as follows: Figure 7 , 8 As shown, the fixing frame 8 includes a mounting plate 801 , an adjusting seat 803 and an adsorption member 804 , the adjusting seat 803 is fixedly installed on the mounting plate 801 , and the mounting plate 801 is installed on the top of the test box 2 , and the adsorption member 804 is installed on the adjusting seat 803 Above, the fixing frame 8 also includes mounting bolts 802, the mounting bolts 802 are arranged on the mounting plate 801, and the mounting plate 801 is fixedly installed on the test box 2 through the mounting bolts 802, and the adjusting seat 803 and the adsorption member 804 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com