Zinc oxide antibacterial polypropylene pipeline convenient to connect

An antibacterial polypropylene and zinc oxide technology, applied in the direction of pipeline connection arrangement, pipe/pipe joint/fitting, mechanical equipment, etc., can solve the problems of time-consuming and laborious, inconvenient connection, etc., to improve efficiency, facilitate connection and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

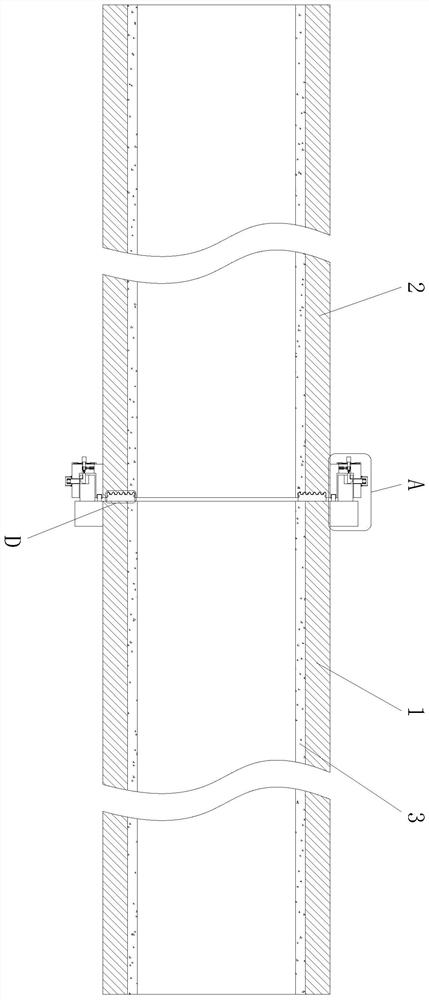

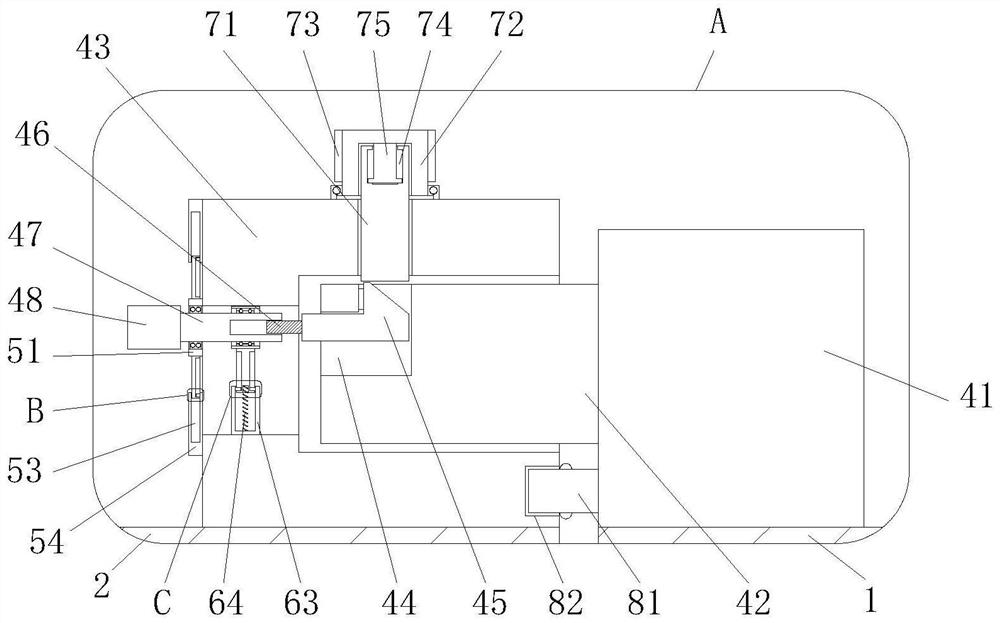

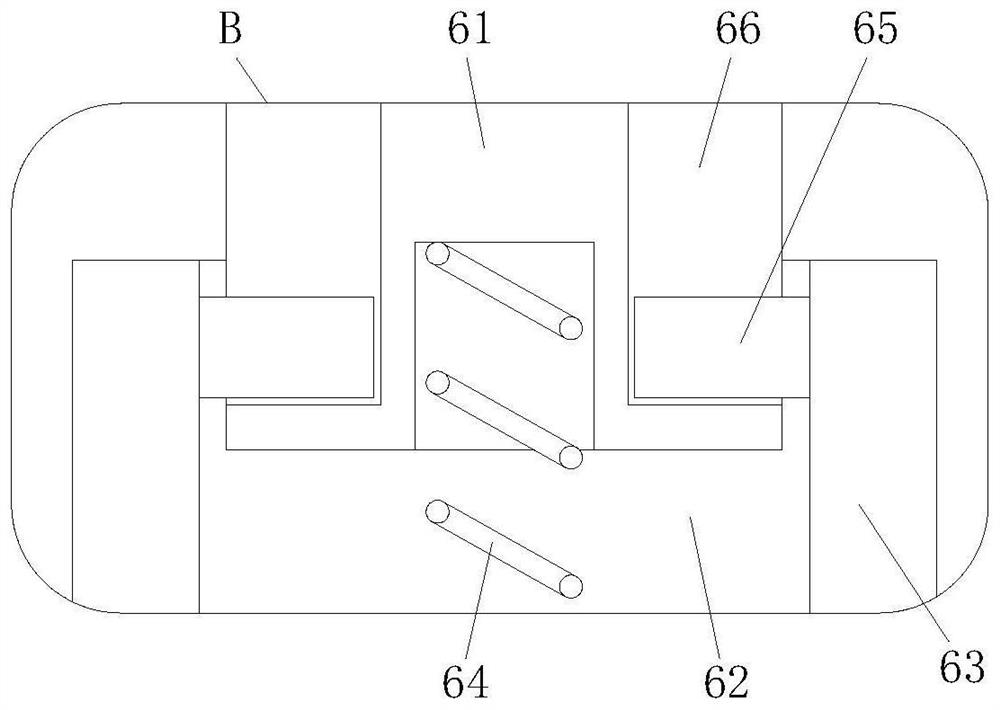

[0029] see Figure 1-7 As shown, a zinc oxide antibacterial polypropylene pipe that is easy to connect includes a first pipe 1, a second pipe 2 and a zinc oxide coating 3; one side of the first pipe 1 is provided with a second pipe 2, and the The inner wall of the first pipe 1 is fixedly connected with a zinc oxide coating 3, and a connecting mechanism 4 is arranged between the first pipe 1 and the second pipe 2; the connecting mechanism 4 includes a fixed block 41, an insert block 42, a connection The seat 43, the connecting groove 44, the connecting block 45, the screw 46, the screw sleeve 47, the reset assembly, the releasing assembly and the sealing assembly, the fixed block 41 is fixedly connected to the two ends of the first pipe 1 close to the second pipe 2 side, The inserting block 42 is fixedly connected with the fixing block 41, and the inserting block 42 is inserted inside the connecting seat 43, and the connecting seat 43 is fixedly connected to the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com