Building wall surface mortar smearing construction process

A construction technology and technology for building walls, applied in the field of mortar application, can solve the problems of time-consuming and labor-intensive manual application, low degree of automation, and affecting work efficiency, and achieve the effects of high degree of automation, improved automation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

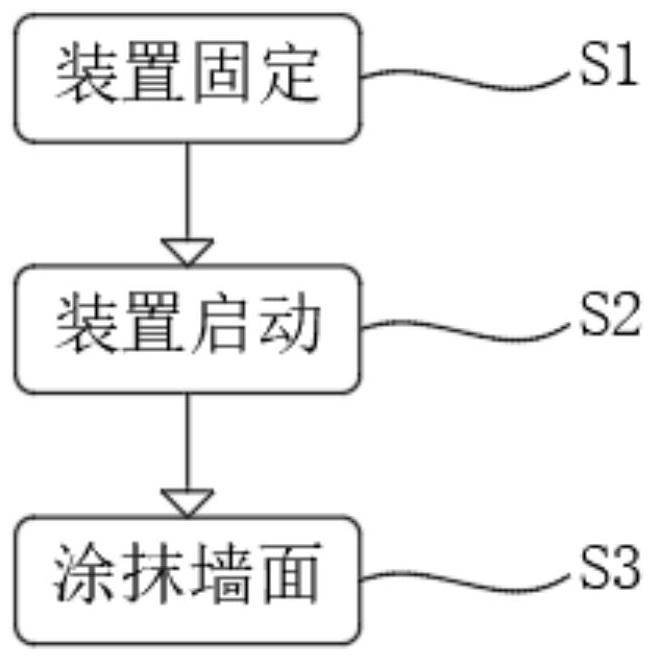

[0033] see Figure 1 to Figure 9 , a construction technique for applying mortar on the surface of a building wall, characterized in that it comprises the following steps;

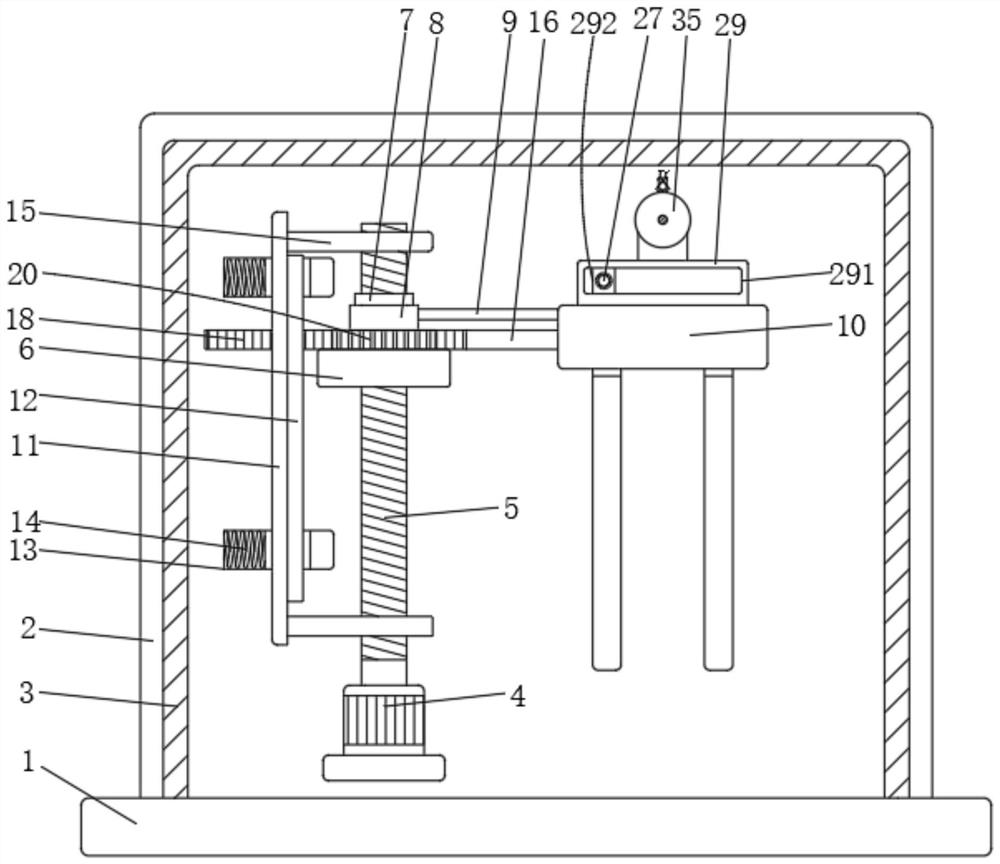

[0034] Step S1, device fixing: move the mortar applicator to a position facing the wall, and fix the base 1;

[0035] see Figure 2 to Figure 9, the mortar applicator includes a base 1, a moving plate 11 and a cylinder 17. The surface of the base 1 is fixed with a fixed plate 2, the surface of the fixed plate 2 is fixedly installed with a motor 4, the output end of the motor 4 is fixed with a threaded rod 5, and the surface of the fixed plate 2 slides A U-shaped plate 10 is connected, and a sleeve block 6 is threadedly connected to the surface of the threaded rod 5 . A connecting block 7 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com