Double-wall steel cofferdam construction method

A technology of double-walled steel cofferdam and construction method, which is applied in basic structure engineering, construction and other directions, can solve the problems of difficult excavation of the bottom layer, complicated operation, low efficiency, etc., to reduce the difficulty of deviation correction operation, simple and convenient assembly operation, and convenient operation. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] A construction method for a double-walled steel cofferdam, comprising the following steps:

[0084] Step 1, after the construction of the pile foundation is completed, the drilling platform is removed.

[0085] Step 2, install the assembly platform on the steel casing.

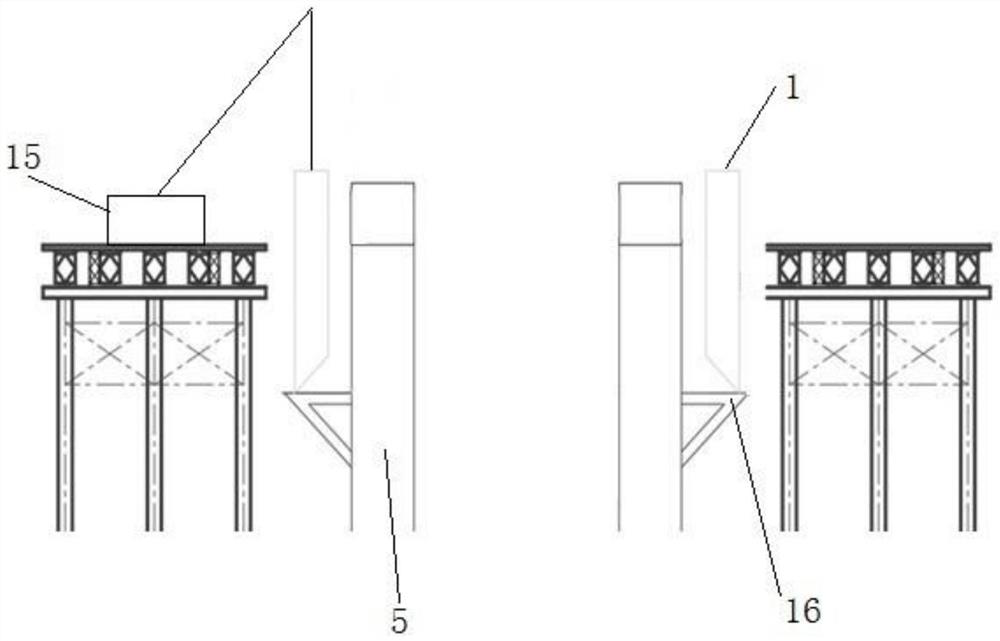

[0086] The nine steel casings 5 are divided into three rows, and three steel casings 5 are evenly distributed in each row in a square distribution. The steel casing includes 4 corner pile steel casings 51 and 4 side middle steel casings 52 and 1 central steel casing. The center of the edge, the center steel guard is located in the center of the square.

[0087] After the assembly platform is installed, the four corner pile steel casings 51 are lengthened.

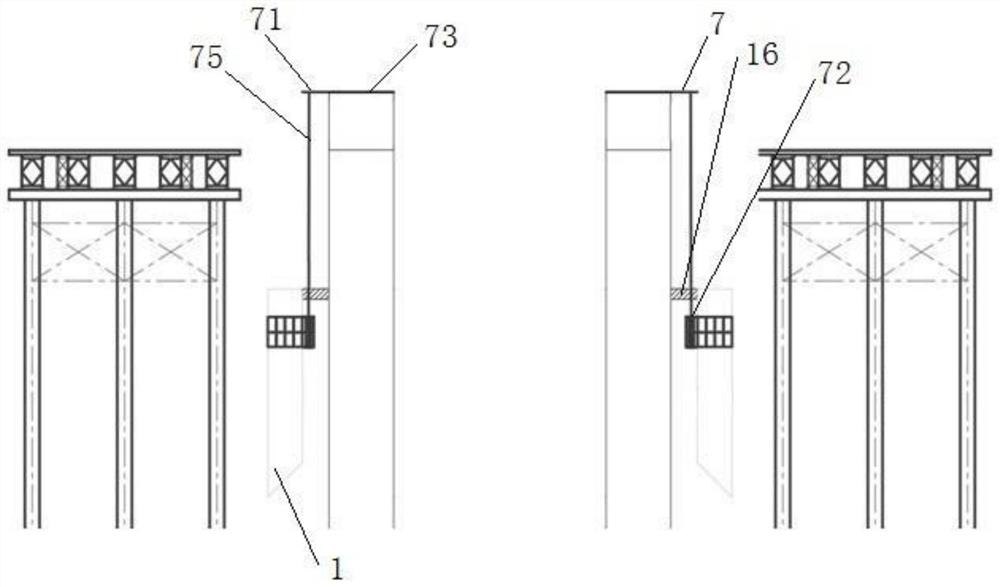

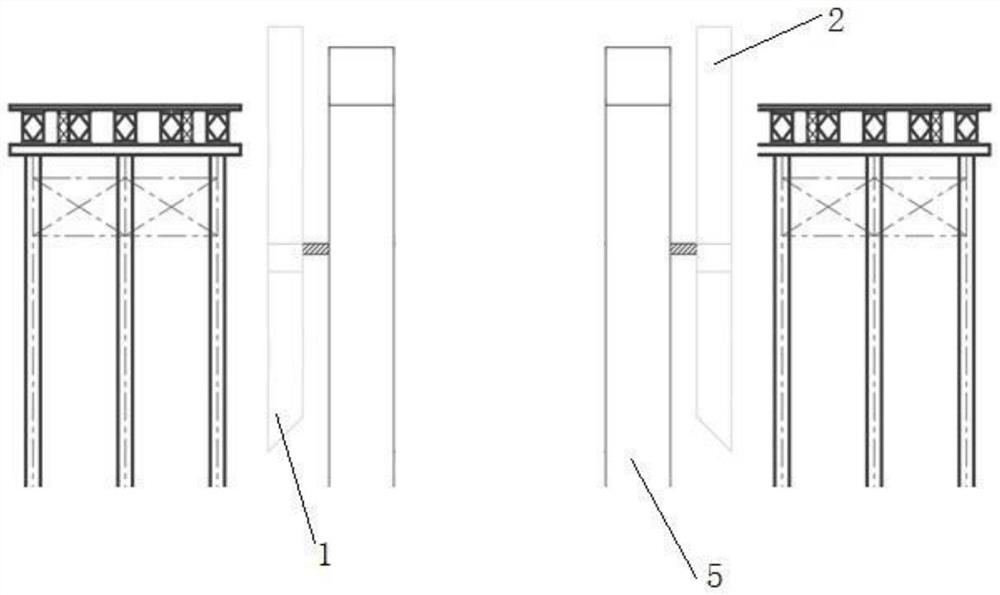

[0088] Step 3: Assembling and lowering the double-walled steel cofferdam.

[0089] The double-walled steel cofferdam includes three sections, and each section of the double-walled steel cofferdam is a square structure composed of 8 side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com