Assistant for continuously reducing flame retardant property of flame-retardant paper

A technology of flame retardant performance and flame retardant paper, applied in papermaking, paper, textiles and papermaking, etc., can solve the problems of reduced combustion performance, reduced combustion performance, crystallization and other problems of flame retardant paper, and achieve enhanced flame retardant performance and flame retardant efficiency. High, improve the effect of related performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

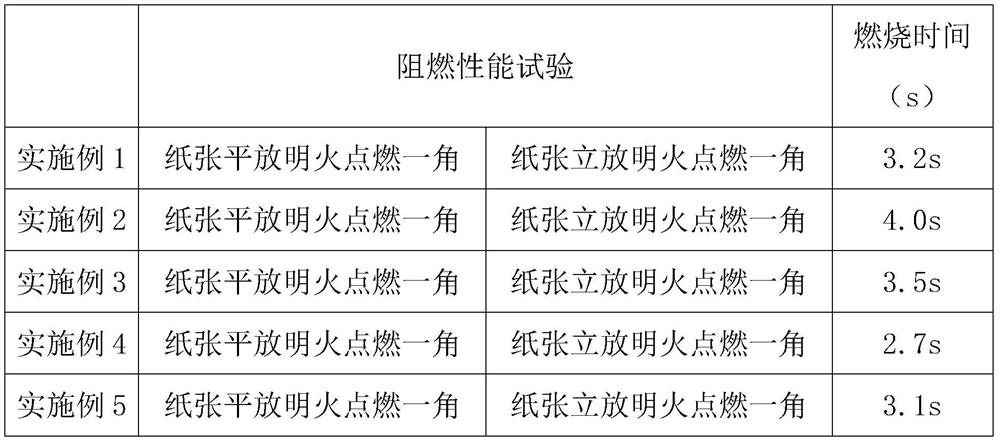

Embodiment 1

[0034] First, the auxiliary agent for the continuous decrease of the flame retardant performance of the flame retardant paper of the present invention is prepared according to the following steps:

[0035] S1: prepare corn gelatinized starch, accurately weigh corn gelatinized starch and LS-2 type anionic starch according to the proportioning, wherein the proportioning is: corn gelatinized starch: LS-2 type anionic starch=7:1;

[0036] S2. Add the above-measured corn gelatinized starch and LS-2 type anionic starch together into a clean container, fully stir to make the corn gelatinized starch and LS-2 type anionic starch completely mixed, and the stirring speed during mixing is 2300rpm , the stirring time is 2h, and then heated to above 80 °C to make it gelatinized to obtain a gelatinized auxiliary;

[0037] S3. Take another clean container, add deionized water and the above gelatinized adjuvant into it, stir to make it fully mixed, and dilute the gelatinized adjuvant to a conc...

Embodiment 2

[0040] First, the auxiliary agent for the continuous decrease of the flame retardant performance of the flame retardant paper of the present invention is prepared according to the following steps:

[0041] S1: prepare corn gelatinized starch, accurately weigh corn gelatinized starch and LS-2 type anionic starch according to the proportioning, wherein the proportioning is: corn gelatinized starch: LS-2 type anionic starch=7:3;

[0042] S2. Add the above-measured corn gelatinized starch and LS-2 type anionic starch together into a clean container, fully stir to make the corn gelatinized starch and LS-2 type anionic starch completely mixed, and the stirring speed during mixing is 2300rpm , the stirring time is 2h, and then heated to above 80 °C to make it gelatinized to obtain a gelatinized auxiliary;

[0043] S3. Take another clean container, add deionized water and the above gelatinized adjuvant into it, stir to mix well, and dilute the gelatinized adjuvant to a concentration o...

Embodiment 3

[0046]First, the auxiliary agent for the continuous decrease of the flame retardant performance of the flame retardant paper of the present invention is prepared according to the following steps:

[0047] S1: prepare corn gelatinized starch, accurately weigh corn gelatinized starch and LS-2 type anionic starch according to the proportioning, wherein the proportioning is: corn gelatinized starch: LS-2 type anionic starch=8:1;

[0048] S2. Add the above-measured corn gelatinized starch and LS-2 type anionic starch together into a clean container, fully stir so that the corn gelatinized starch and LS-2 type anionic starch are completely mixed, and the stirring speed during mixing is 2300rpm , the stirring time is 2h, and then heated to above 80 °C to make it gelatinized to obtain a gelatinized auxiliary;

[0049] S3. Take another clean container, add deionized water and the above gelatinized adjuvant into it, stir to mix well, and dilute the gelatinized adjuvant to a concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap